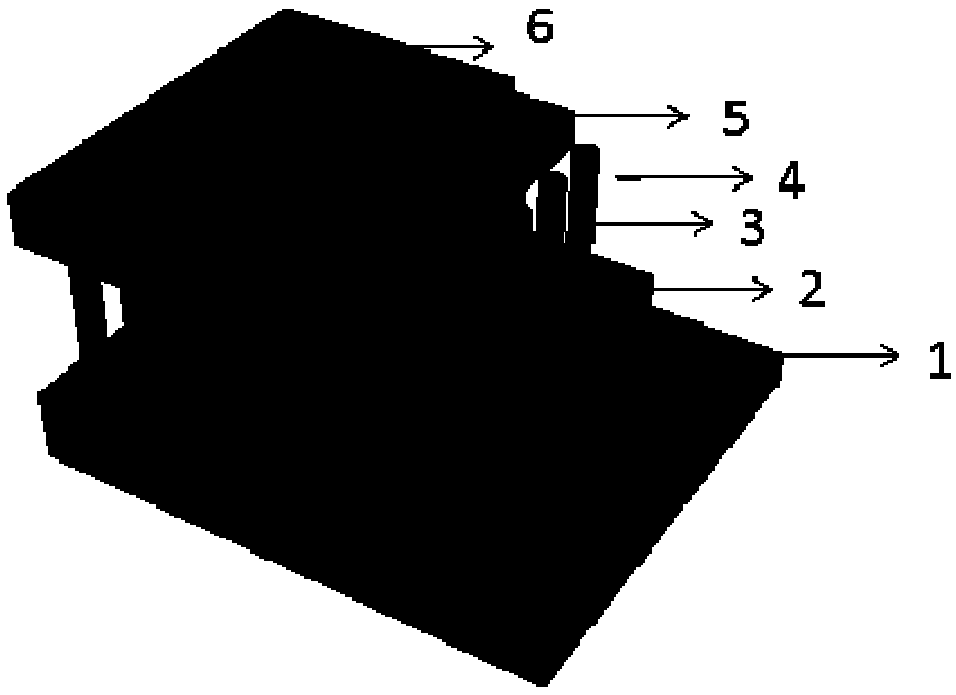

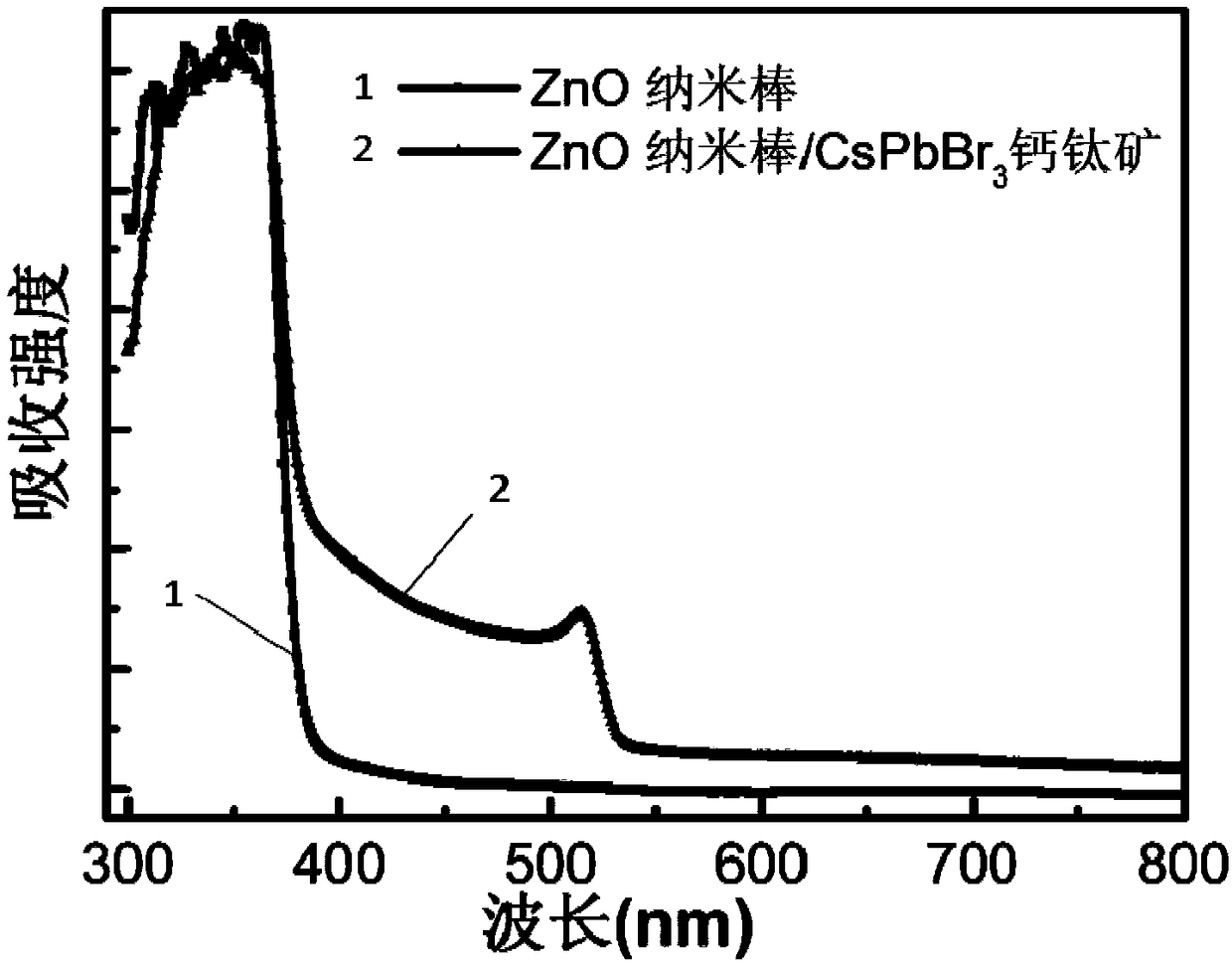

A purely inorganic photodetector based on the zno/cspbbr3/moo3 structure

An inorganic photoelectric and detector technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of limited development, poor stability, etc., and achieve the effect of clear overall structure, high stability, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: 12nm thickness MoO3 Preparation of detectors:

[0041] (1) Ultrasonic the transparent conductive glass FTO with deionized water, acetone, and alcohol for 15 minutes respectively, and then treat it with ultraviolet ozone environment for 30 minutes.

[0042] (2) The ZnO seed layer is prepared by spin coating. Dissolve 1.5M zinc acetate solution in methanol solution and stir for 10 minutes, and spin-coat on FTO at a speed of 5000r / min for 20 seconds. Dry at 100°C for 10 minutes, and then transfer to a horse-boiling furnace for annealing for 2 hours.

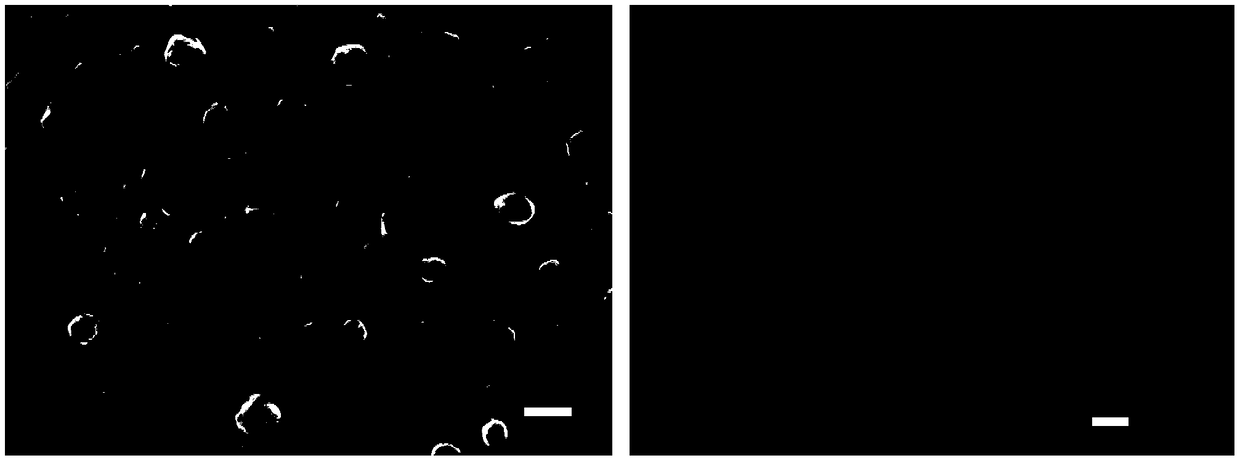

[0043] (3) ZnO nanorods were prepared by water bath method. Add 0.6g polyetherimide (PEI) into 150ml deionized water and stir, then add 50mmol / L zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and 30mmol / L hexamethylenetetramine (C 6 h 12 N 4 ), fully stirred for 30 minutes, put the annealed sample in step (2) into the solution, reacted for 10 minutes at 88.5 degrees, took it out of the solution, and dried t...

Embodiment 2

[0049] Example 2: MoO with different thicknesses 3 Preparation of the detector:

[0050] (1) Ultrasonic the transparent conductive glass FTO with deionized water, acetone, and alcohol for 15 minutes respectively, and then treat it with ultraviolet ozone environment for 30 minutes.

[0051] (2) The ZnO seed layer is prepared by spin coating. Dissolve 1.5M zinc acetate solution in methanol solution and stir for 10 minutes, and spin-coat on FTO at a speed of 5000r / min for 20 seconds. Dry at 100°C for 10 minutes, and then transfer to a horse-boiling furnace for annealing for 2 hours.

[0052] (3) ZnO nanorods were prepared by water bath method. Add 0.6g polyetherimide (PEI) into 150ml deionized water and stir, then add 50mmol / L zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and 30mmol / L hexamethylenetetramine (C 6 h 12 N 4 ), fully stirred for 30 minutes, put the annealed sample in step (2) into the solution, reacted for 10 minutes at 88.5 degrees, took it out of the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com