Method for preparing super-hydrophobic copper coating on surface of aluminum alloy

A technology of aluminum alloy surface and copper coating, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve problems such as peeling and weak bonding, and achieve a wide range of applications, simple process and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0022] (1) Grind the 6061 aluminum alloy sample with metallographic water sandpaper step by step from 300# to 2000#, and ultrasonically clean the polished sample with acetone, absolute ethanol, and deionized water for 5 minutes to remove surface impurities and oil stains ;

[0023] (2) Treat the aluminum alloy sample prepared above in alkaline washing solution (20g / L NaOH aqueous solution) for 5 minutes to further remove impurities and oil stains on the surface, and improve the reactivity of the surface. After taking it out, wash it with a large amount of deionized water Rinse, remove residual alkaline wash, and dry quickly;

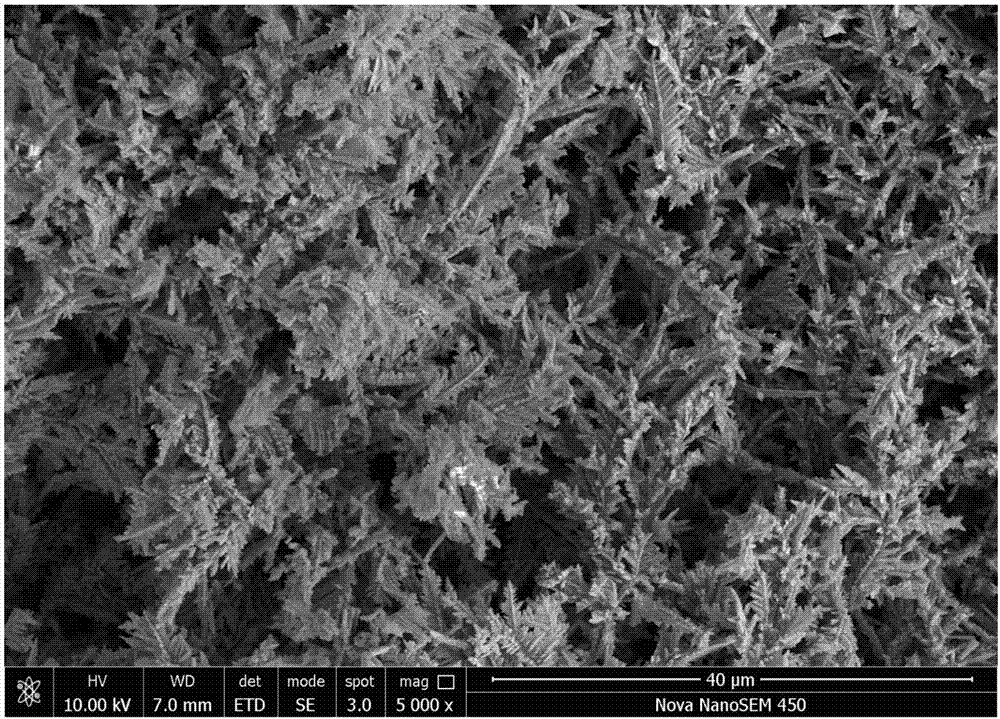

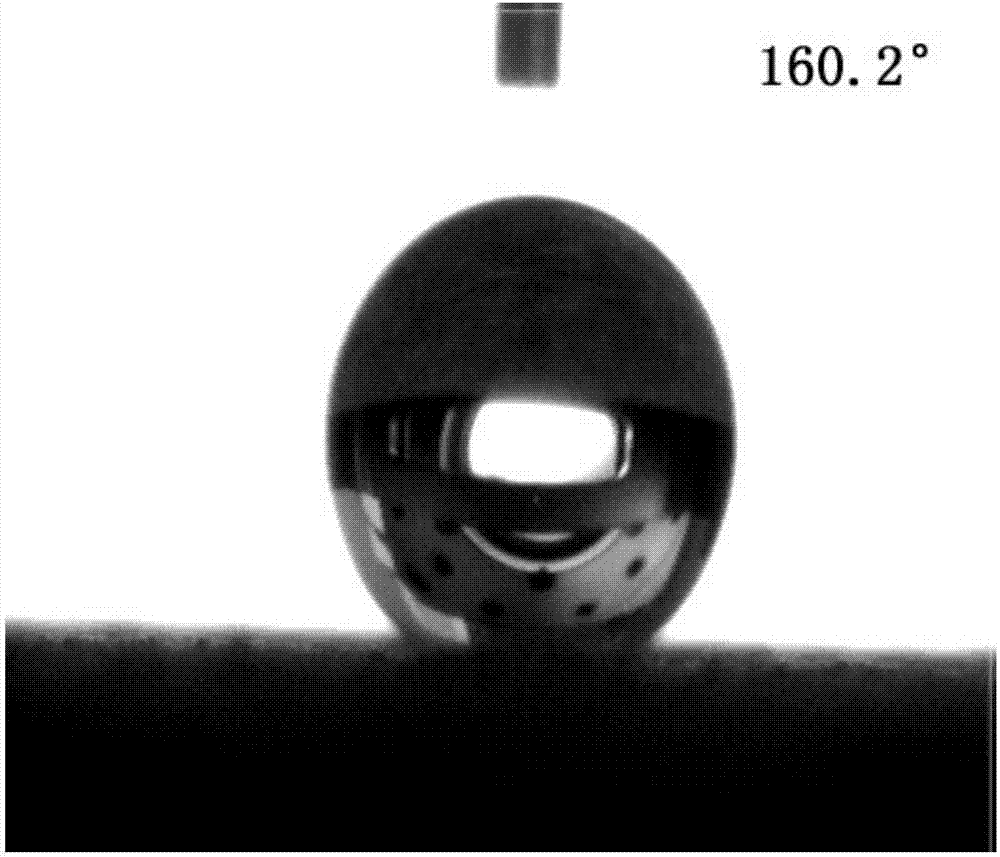

[0024] (3) Put the above-mentioned treated aluminum alloy sample into the CuSO2 sample of 50g / L 4 ·5H 2 O and 5g / L FeCl 3 ·6H 2 The chemical reaction is carried out in the mixed aqueous solution composed of O, and the reaction time is 1min. After the reaction, the sample is placed in a drying oven and dried at 60°C to obtain a copper coating with a f...

specific Embodiment 2

[0027] (1) Polish the pure aluminum sample with metallographic water sandpaper step by step from 300# to 2000#, and ultrasonically clean the polished sample with acetone, absolute ethanol, and deionized water for 6 minutes to remove surface impurities and oil stains;

[0028] (2) Treat the pure aluminum sample prepared above in alkaline washing solution (10g / L NaOH aqueous solution) for 5 minutes to further remove impurities and oil stains on the surface and improve the reactivity of the surface. After taking it out, wash it with a large amount of deionized water Rinse, remove residual alkaline wash, and dry quickly;

[0029] (3) Put the above-mentioned processed pure aluminum sample into the CuSO2 of 25g / L 4 ·5H 2 O and 5g / L FeCl 3 ·6H 2 The chemical reaction is carried out in the mixed aqueous solution composed of O, and the reaction time is 2min. After the reaction, the sample is placed in a drying oven and dried at 80°C to obtain a copper coating with a feather-like mic...

specific Embodiment 3

[0032] (1) Grind the 6061 aluminum alloy sample with metallographic water sandpaper step by step from 300# to 2000#, and ultrasonically clean the polished sample with acetone, absolute ethanol, and deionized water for 8 minutes to remove surface impurities and oil stains ;

[0033] (2) Treat the aluminum alloy sample prepared above in alkaline washing solution (30g / L NaOH aqueous solution) for 5 minutes to further remove impurities and oil stains on the surface and improve the reactivity of the surface. After taking it out, wash it with a large amount of deionized water Rinse, remove residual alkaline wash, and dry quickly;

[0034] (3) Put the above-mentioned processed aluminum alloy sample into the CuSO4 sample of 75g / L 4 ·5H 2 O and 10g / L FeCl 3 ·6H 2 The chemical reaction is carried out in the mixed aqueous solution composed of O, and the reaction time is 2min. After the reaction, the sample is placed in a drying oven and dried at 100°C to obtain a copper coating with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com