Electron back-scattering diffraction (EBSD) sample preparation method for cemented carbide powder

A cemented carbide and powder technology, which is applied in the field of cemented carbide powder EBSD sample preparation, achieves the effects of high test repeatability, easy realization, and saving sintering cost and test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

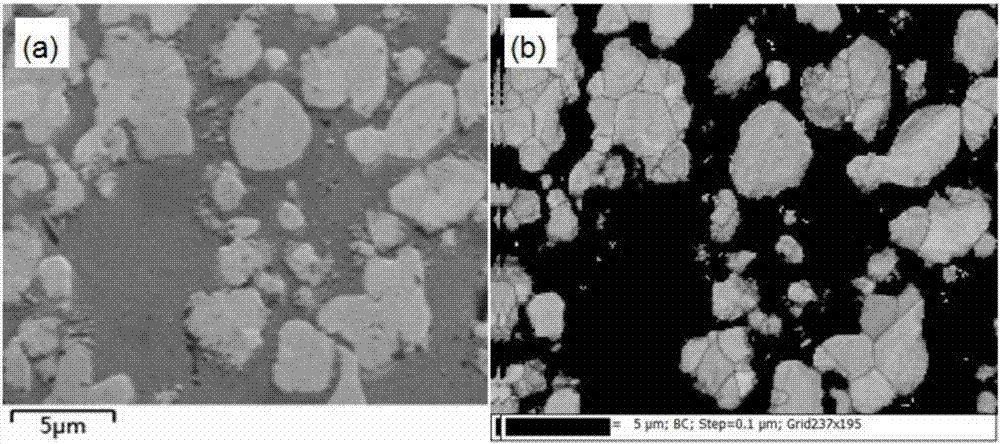

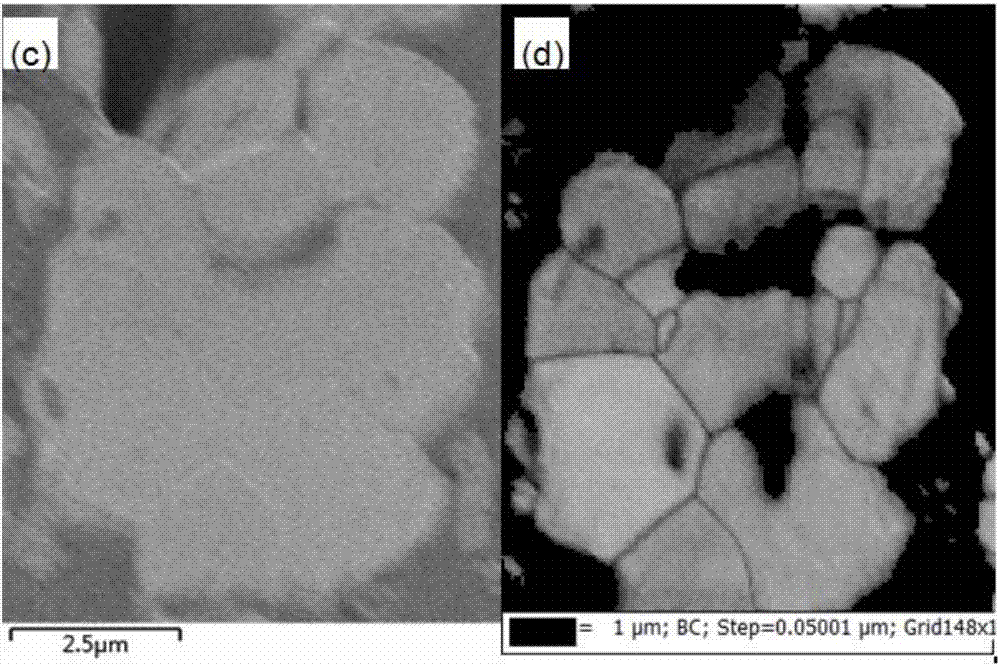

[0061] In the present embodiment, cemented carbide powder takes 5 μm WC raw material powder as an example, selects 5 μm WC raw material powder sample, prepares EBSD sample and tests, the result is as follows figure 1 and figure 2 As shown, the specific steps are:

[0062] Ingredients: Use an electronic balance to weigh 10g each of 5μm WC raw material powder and 200-mesh analytical electrolytic Cu powder (Kermel reagent) at a weight percentage of 1:1, and grind and mix them in a mortar for 30 minutes.

[0063] Compression molding: Struer Citopress-1 mosaic instrument is used to compress the well-proportioned WC / Cu mixed powder, the compression pressure is about 20KN, and the diameter of the compact is 25mm.

[0064] Sintering: Cut a block with a size of about 3mm from the pressed compact and put it into a thermal analyzer DSC Al 2 o 3 Crucible, and then placed on the STA449F3 thermal analyzer support, close the cavity. First vacuumize the cavity, then use Ar protection, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com