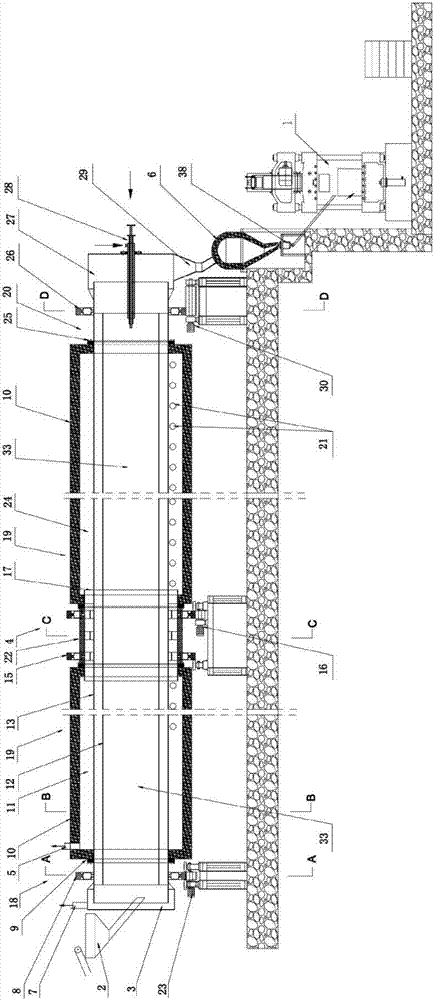

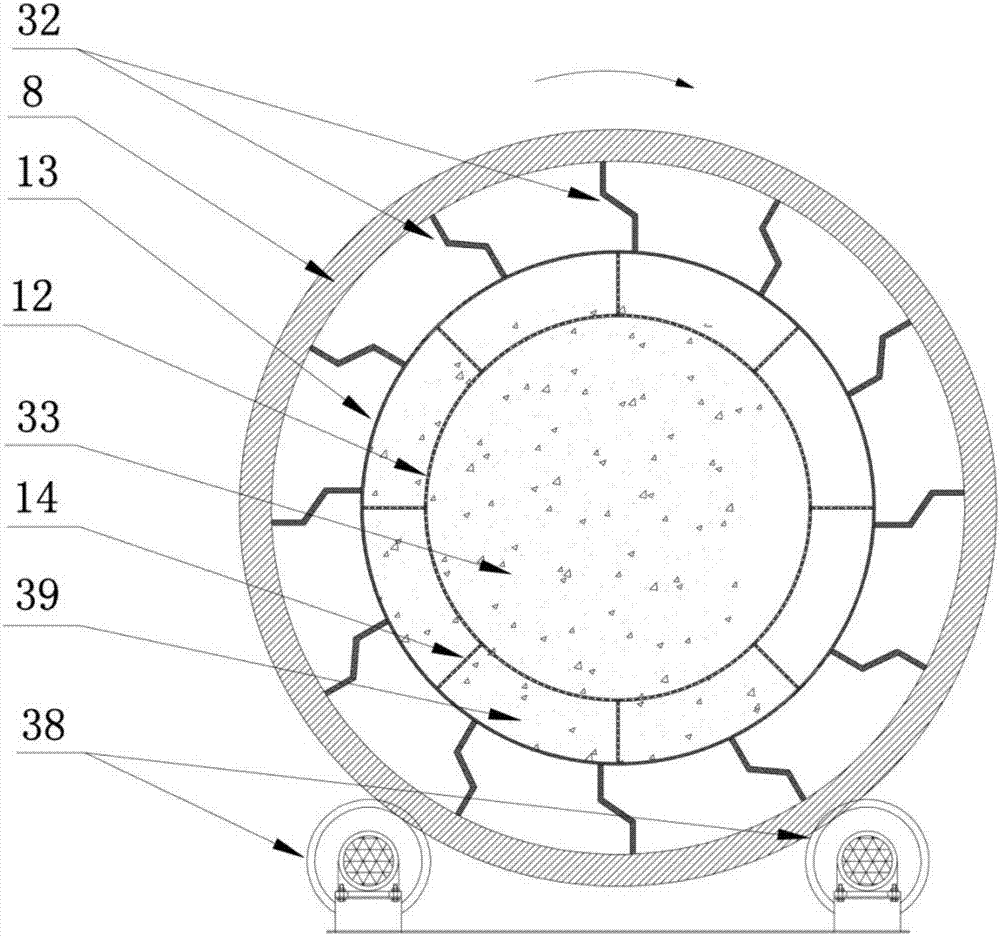

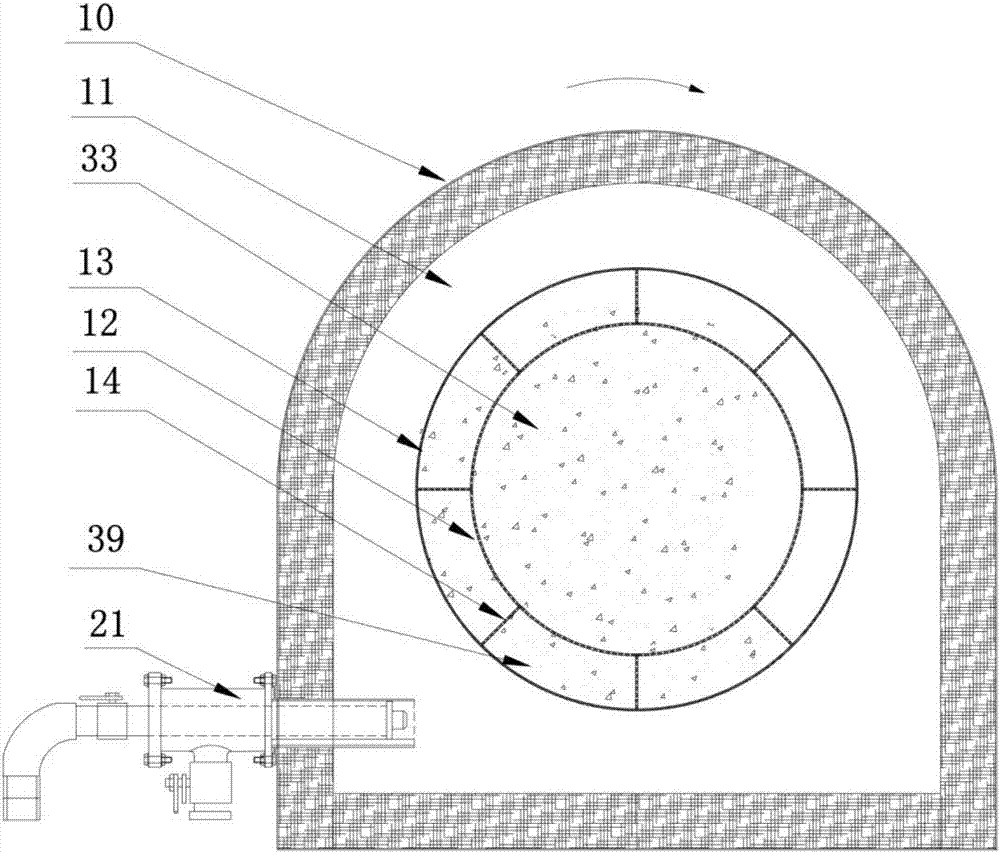

Gas-based DRI (direct-reduced iron) device and rapid iron reduction method

A reduced iron, direct technology, applied in the direction of fluidized bed furnace, furnace, furnace type, etc., can solve the problems of scrap steel backlog, casting difficult to buy, etc., and achieve the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 (secondary reduced iron powder)

[0082]Adopt TFe73.2% ordinary carbon steel oxide scale, grinding fineness to 200 mesh, pass rate 100%; use the gas-based direct reduction iron method device of the present invention, add a flame-trap type rotary reduction kiln with a diameter of ¢159mm×1500mm Inside, silicon carbide rods are used to heat through the flame, and at the center point of the kiln hood, the hydrogen channel of the three-channel spray gun assembly is used to feed H 2 , the pressure is 1200Pa, the reduction temperature is 870°C, after 5 hours of deep reduction, stop heating, H 2 After the pressure was reduced to 400Pa and continued to supply hydrogen for 8 hours, the temperature of the material reached 86°C, the reduced iron powder was taken out, and its indicators were tested, as shown in Table 1.

[0083] Table 1

[0084]

Embodiment 2

[0085] Embodiment 2 (medium and low-end mechanical parts - counterweight iron block)

[0086] TFe69.68% iron ore powder is used, and the grinding fineness is 200 mesh, and the passing rate is 100%. The air-based direct reduction iron method device of the present invention is used, and a flame-insulated rotary reduction kiln with a diameter of ¢159mm×1500mm is added, and silicon Carbon rods are heated by flame insulation, and water gas (mainly composed of H 2 and CO), the pressure is 1350Pa, the reduction temperature is 990°C, after reduction for 3.2 hours, a small amount of water vapor (saturated steam) is injected into the center point of the kiln head cover for about 0.5 hours through the water vapor channel of the three-channel spray gun assembly; stop Introduce water vapor and stop gas supply, use the hydrogen channel of the three-channel spray gun assembly to continue to inject H 2 , after reducing for 0.5h, stop heating, directly add hot reduced iron powder into the mol...

Embodiment 3

[0090] Embodiment 3 (medium and high-end mechanical parts)

[0091] The ultra-pure iron powder of TFe71.8% is used, and other indicators all meet the requirements of powder metallurgy ultra-pure iron fine powder, and the grinding fineness reaches 200 mesh, and the pass rate is 100%; ¢159mm×1500mm flame-chambered rotary reduction kiln, adopts silicon carbon rods to heat the flame-chambered furnace, and uses the hydrogen channel of the three-channel spray gun assembly to inject H into the central point of the kiln hood. 2 , the pressure is 1250Pa, the reduction temperature is 880°C, after reduction for 3.5 hours, stop adding, directly heat the hot reduced iron powder into the mold of a 1250t hydraulic press, and then freely roll it into a round steel bar of about ¢30mm, after cooling , processed it into a round bar sample of ¢16mm, and measured its density to be 7.81t / m 3 , and its physical indicators are shown in Table 3 after testing.

[0092] table 3

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com