Denitrification slow release filler as well as preparation and application methods thereof

A denitrification and slow-release technology, applied in chemical instruments and methods, waste fuel, anaerobic digestion treatment, etc., can solve the problems of unsatisfactory denitrification and denitrification effect, and achieve good wastewater treatment effect, prolonged residence time, high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

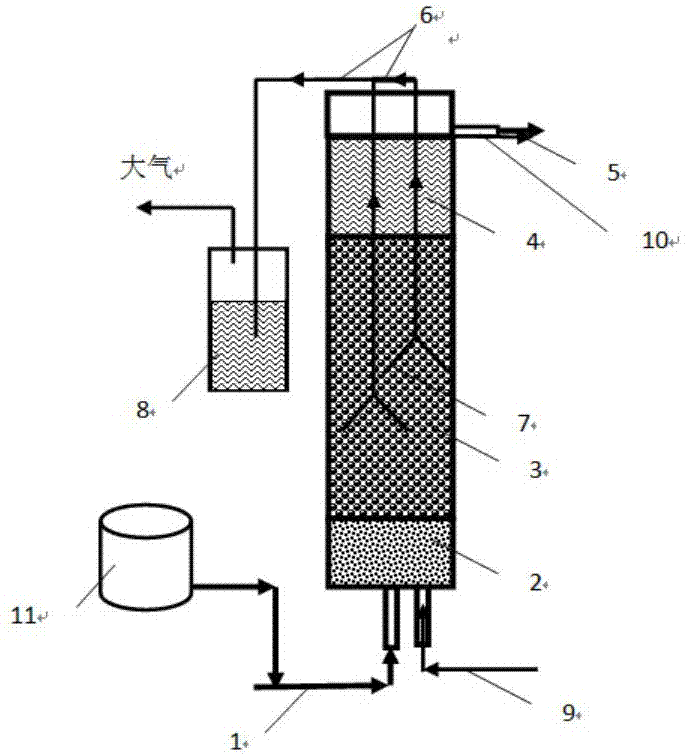

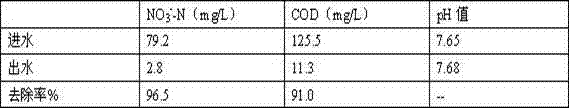

Embodiment 1

[0032] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, polybutylene succinate, polycaprolactone and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 20:1:1:1, and filled to ZHDN with a height of 3m and an inner diameter of 0.5m -In the B2 type reactor, the filler is filled in layers according to the particle size of 30mm, 20mm, 15mm, 10mm, and 5mm from bottom to top, and the filler and anionic clay are mixed into the reactor in a ratio of 10:1. Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to the tap water to prepare water with a concentration of nitrate nitrogen of 80 mg / L to simulate the water quality of sewage, start the dosing system, and remove 30 mg of NO 3 - - Dosing carbon source methanol at a dose of N / L, the raw water is pumped into the reactor from the bottom of the reactor through a peristaltic pump, the hydraulic ret...

Embodiment 2

[0036] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, polybutylene succinate, polycaprolactone and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 25:1:2:2, and filled to ZHDN with a height of 3m and an inner diameter of 0.75m -In the B2 type reactor, the fillers are filled in layers according to the particle size of 25mm, 10mm, 5mm, 3mm, and 1mm from bottom to top, and the filler and anionic clay are mixed into the reactor according to the ratio of 50:1. Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to the tap water to prepare water with a concentration of nitrate nitrogen of 80 mg / L to simulate the water quality of sewage, start the dosing system, and remove 30 mg of NO 3 -- Dosing carbon source methanol at a dose of N / L, the raw water is pumped into the reactor from the bottom of the reactor through a peristaltic pump, the h...

Embodiment 3

[0040] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, polybutylene succinate, polycaprolactone and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 10:5:3:3, and filled to a ZHBN- In the B2 type reactor, the filler is filled in layers according to the particle size of 30mm, 25mm, 10mm, 5mm, and 3mm from bottom to top, and the filler and anionic clay are mixed into the reactor according to the ratio of 20:1. Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to the tap water to prepare water with a concentration of nitrate nitrogen of 60mg / L to simulate the water quality of sewage, start the dosing system, and remove 20mg NO 3 - - Dosing carbon source methanol at a dosage of N / L, the raw water is pumped into the reactor from the bottom of the reactor through a peristaltic pump, the hydraulic retention time of the sewage in the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com