Phosphorus-free environmental-friendly metal surface pretreatment liquid and utilization method thereof

A technology for treating liquids and metals, applied in the coating process of metal materials, etc., can solve the problems of easy aging, poor film formation, poor stability, etc., and achieve the effect of excellent weather resistance and aging resistance, good hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

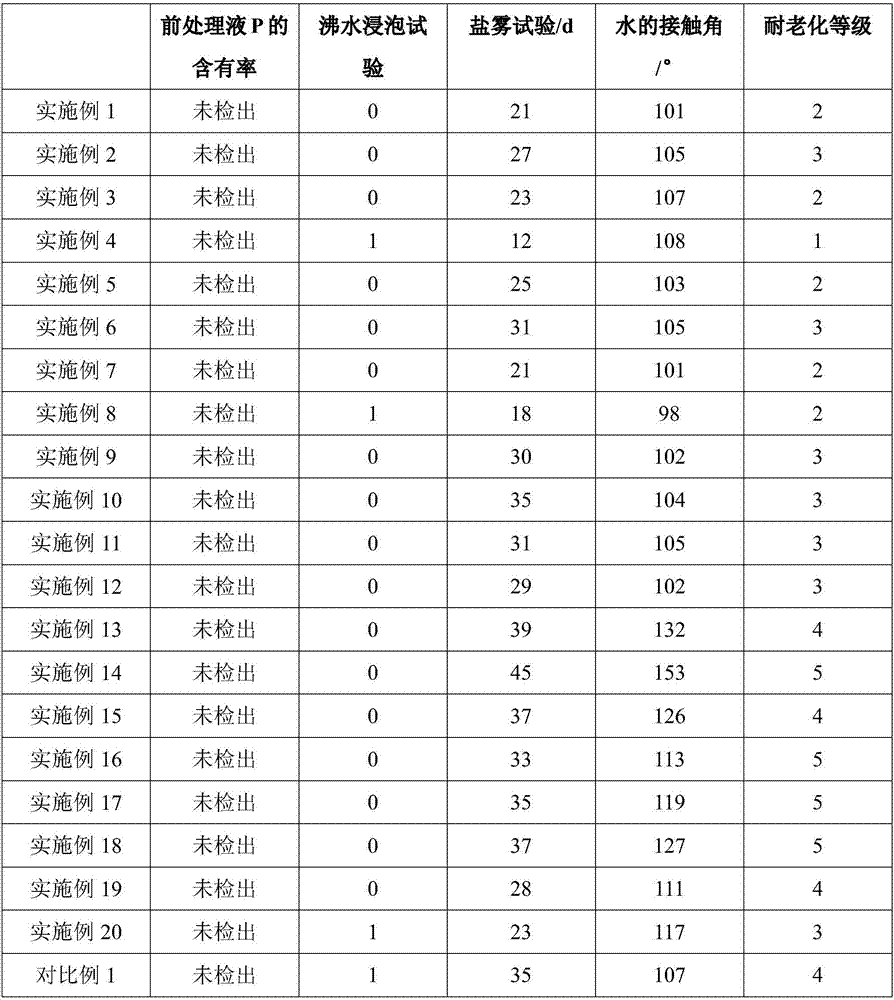

Examples

Embodiment 1-20

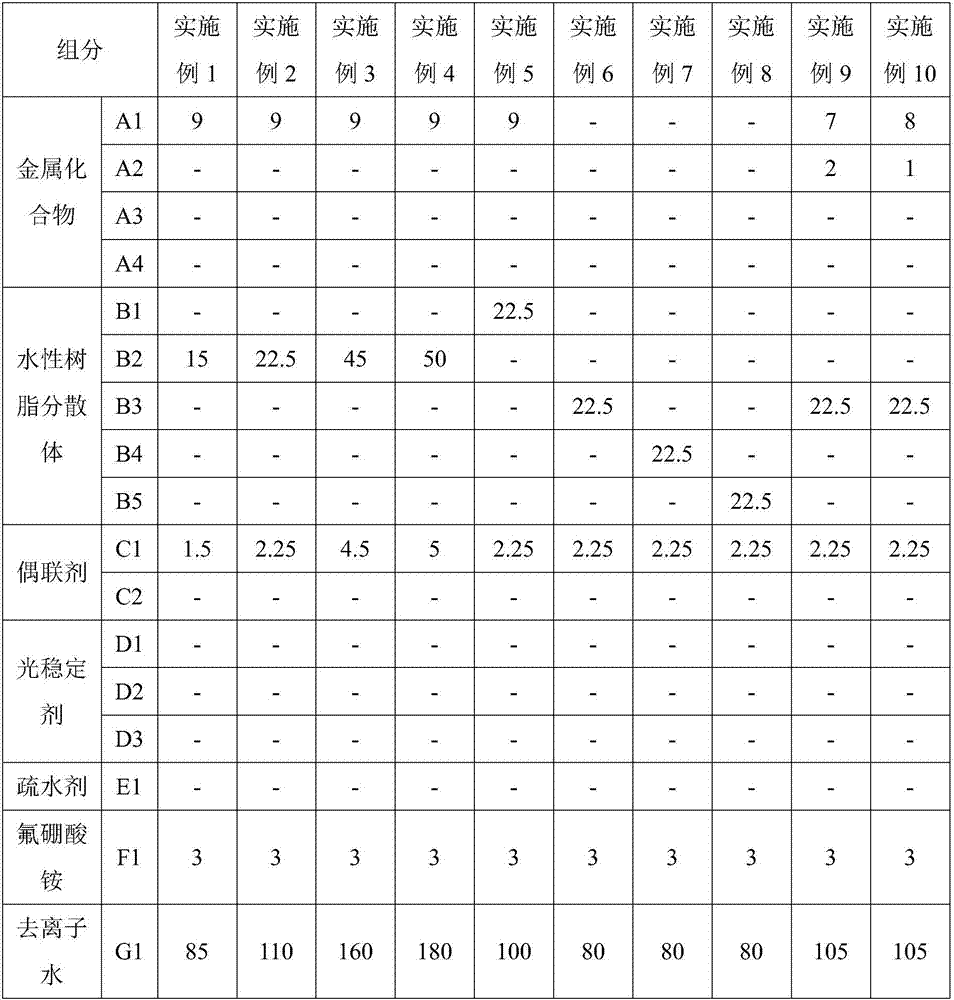

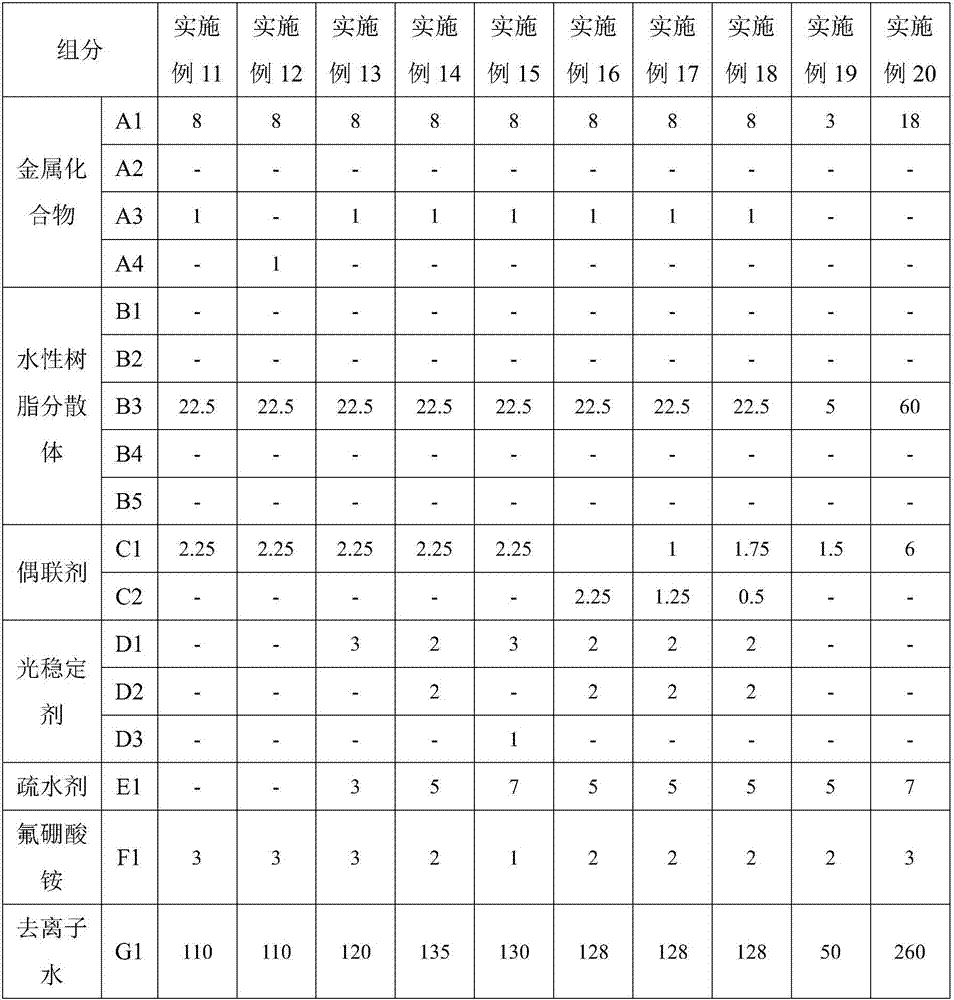

[0077] The present invention prepares phosphorus-free environmental protection metal surface pretreatment liquid according to the prescription in table 1 and table 2, and preparation method is as follows (the consumption of following components is all parts by weight):

[0078] (1) Add the formulated amount of aqueous resin dispersion, coupling agent, hydrophobic agent, and ammonium fluoroborate into deionized water, heat to 60-80°C and stir for 30 minutes, and cool to room temperature to obtain a mixed solution;

[0079] (2) adjusting the pH of the mixed solution obtained in step (1) to 7-12 with a pH regulator;

[0080] (3) adding the metal compound in the formula amount and stirring for 1 hour at normal temperature to obtain the phosphorus-free and environment-friendly metal surface pretreatment solution; wherein,

[0081] The pH regulator is one or more of ammonia water, ammonium fluoride, formic acid, acetic acid, butyric acid, oxalic acid, hydrofluoric acid, nitric acid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com