Determination method for iron, aluminum, manganese, calcium, titanium, silicon and magnesium in casting powder

A determination method and technology for mold slag, applied in the field of laboratory testing, can solve problems such as unfavorable personal health and environmental protection, unsuitable for rapid analysis and production, cumbersome analysis steps, etc. Accurate and reliable results and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

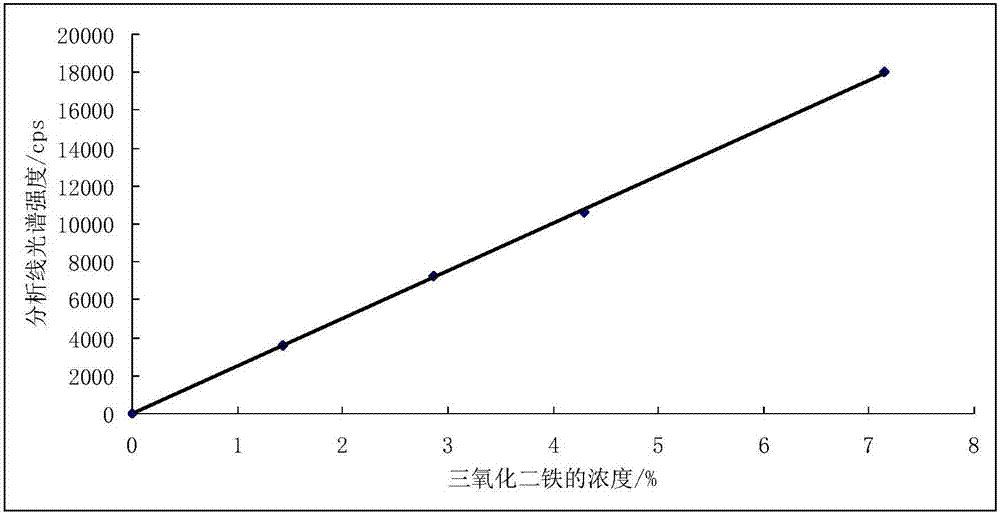

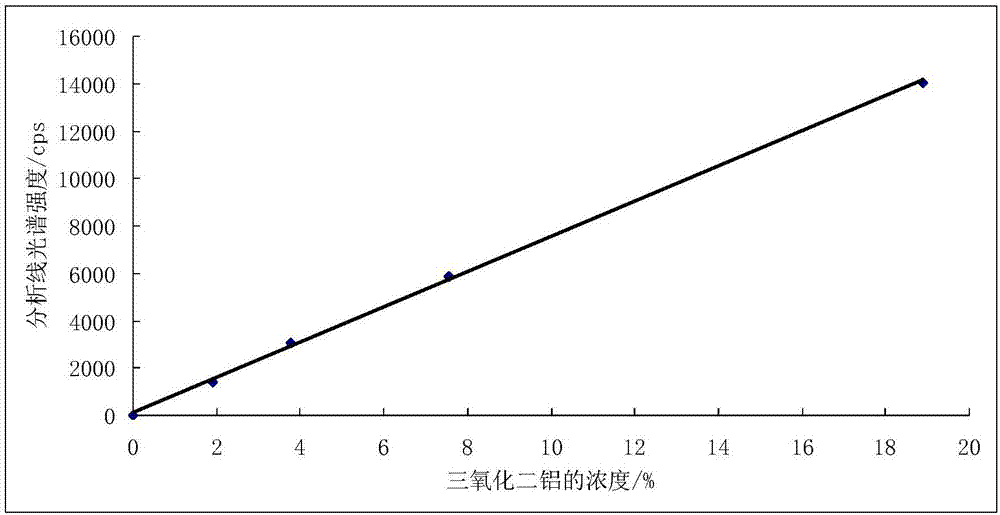

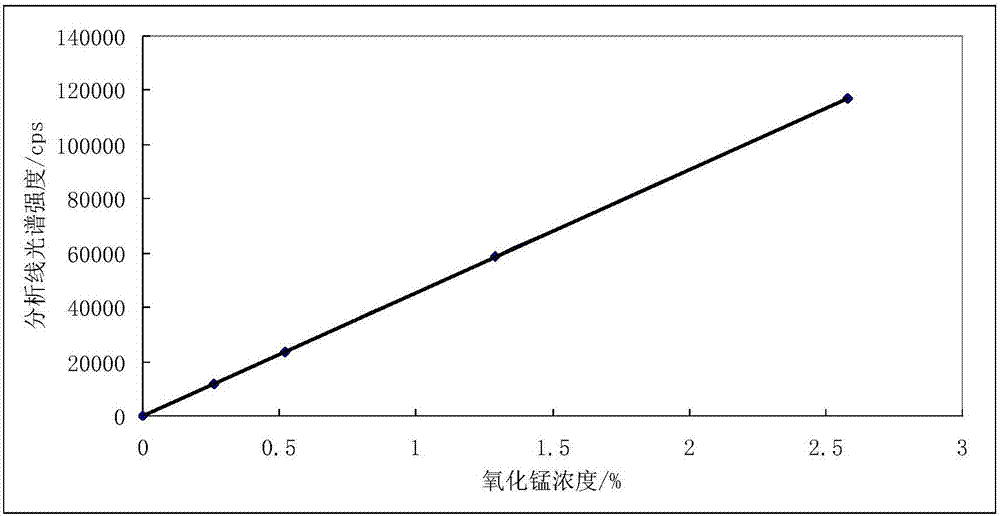

[0045] The method for rapid determination of iron, aluminum, manganese, calcium, titanium, silicon and magnesium components in mold flux in this embodiment includes the following steps:

[0046] 1) Mold slag pre-decarbonization treatment: Weigh 0.2000g mold slag sample into a platinum crucible, put the crucible into a high-temperature muffle furnace at 750°C and burn for 10min, and pre-decarbonize the mold slag.

[0047] 2) Preparation of mold flux sample solution: add 1.4g of mixed flux to the pre-decarbonized and cooled sample, mix well, then cover with 1.0g of mixed flux, melt in a high-temperature furnace at 1000°C for 10min, take out and gently rotate the crucible, Let the melt cool and evenly hang it on the inner wall of the crucible. After the melt cools to room temperature, wash the outer wall of the platinum crucible with water, and place the platinum crucible in a beaker containing 100mL (1+1) hot hydrochloric acid solution. Heat the leached frit on an electric furna...

Embodiment 2

[0066] The method for rapid determination of iron, aluminum, manganese, calcium, titanium, silicon and magnesium components in mold flux in this embodiment includes the following steps:

[0067] 1) Mold slag pre-decarbonization treatment: Weigh 0.2500g mold slag sample into a platinum crucible, put the crucible into a high-temperature muffle furnace at 750°C and burn for 10min, and pre-decarbonize the mold slag.

[0068] 2) Preparation of mold flux sample solution: add 2.5g of mixed flux to the pre-decarbonized and cooled sample, mix well, then cover with 1.0g of mixed flux, melt in a high-temperature furnace at 1000°C for 12min, take out and gently rotate the crucible, Let the melt cool and evenly hang it on the inner wall of the crucible. After the melt cools to room temperature, wash the outer wall of the platinum crucible with water, and place the platinum crucible in a beaker containing 80mL (1+1) hot hydrochloric acid solution. Heat the leached frit on an electric furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com