Postoperative adhesion-resisting polymer thin film and preparation method thereof

A polymer film and anti-adhesion technology, applied in the field of medical supplies, can solve the problems of difficulty in achieving affinity, poor flexibility and impact resistance, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

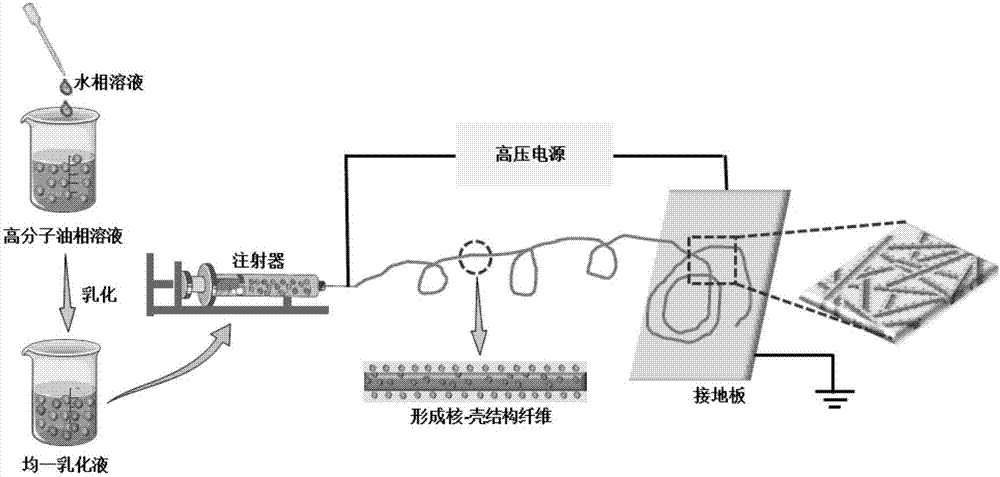

[0030] The embodiment of the present invention discloses a preparation method of postoperative anti-adhesion polymer film, comprising the following steps:

[0031] A), mixing biodegradable polymer materials, emulsifiers and organic solvents to obtain a polymer solution; mixing dextran with water to obtain an aqueous phase solution;

[0032] B), adding the aqueous phase solution into the polymer solution, after mixing and emulsifying, a homogeneous emulsion is obtained;

[0033] C), performing electrospinning on the homogeneous emulsion to obtain an electrospun fiber membrane;

[0034] D), after drying the electrospun fiber membrane, carry out ultraviolet ozone treatment to obtain postoperative anti-adhesion polymer film.

[0035] In the present invention, a biodegradable anti-adhesion film for medical surgery is prepared by using the electrospinning technology with simple process, no pollution in the production process, and energy-saving and high-efficiency. The anti-adhesion...

Embodiment 1

[0045] (1) Preparation of organic phase solution: polyethylene glycol / poly(lactic acid-glycolic acid) (viscosity average molecular weight 100,000) was dissolved in chloroform to prepare a polymer solution with a concentration of 6% (by mass fraction) , adding emulsifier benzyltriethylammonium chloride accounting for 5% (by mass fraction) of polyethylene glycol / poly(lactic acid-glycolic acid) in the above system, magnetically stirred for 5 hours to obtain a uniform organic phase solution ;

[0046] (2) Configuration of aqueous phase solution: Dissolve dextran with a molecular weight of 100,000 in secondary water, configure it into a polymer solution with a concentration of 5% (by mass fraction), and vortex for 3 minutes to obtain a uniform water solution. phase solution;

[0047] (3) Emulsion configuration: drip the aqueous phase solution into the organic phase solution drop by drop, set the number of revolutions of the high-speed shear to be 4000 rpm, mix and emulsify to obta...

Embodiment 2

[0052] (1) Preparation of organic phase solution: polyethylene glycol / poly(lactic acid-glycolic acid) (viscosity average molecular weight 100,000) was dissolved in chloroform to prepare a polymer solution with a concentration of 6% (by mass fraction) , adding emulsifier benzyltriethylammonium chloride accounting for 5% (by mass fraction) of polyethylene glycol / poly(lactic acid-glycolic acid) in the above system, magnetically stirred for 5 hours to obtain a uniform organic phase solution ;

[0053] (2) Configuration of aqueous phase solution: Dissolve dextran with a molecular weight of 100,000 in secondary water, configure it into a polymer solution with a concentration of 5% (by mass fraction), and vortex for 3 minutes to obtain a uniform water solution. phase solution;

[0054] (3) Emulsion configuration: drip the aqueous phase solution into the organic phase solution drop by drop, set the number of revolutions of the high-speed shear to 4000 rpm, mix and emulsify to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com