Low-air-entraining delayed coagulation type polycarboxylate superplasticizer and preparation method thereof

A technology of retarding polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures, can solve the problems of low air content water reducing agent, etc., achieve low air content, good bonding effect, and change the effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

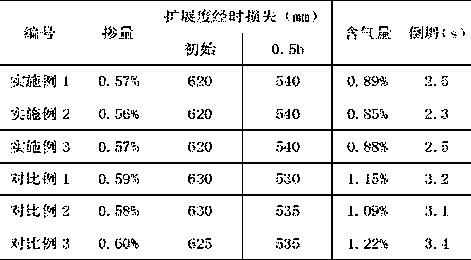

Examples

Embodiment 1

[0021] The raw materials of the following mass components were selected: 1.2 parts of macromonomer, 0.1 part of acrylic acid, 0.2 part of sodium methacrylate sulfonate, 0.01 part of 2-hydroxyethyl methacrylate phosphate, 0.005 part of silane-modified graphene, and 0.00015 parts of ammonium sulfate, 0.0002 parts of neutralizing agent, 3 parts of water, and the ratio of isopentenyl:polyoxyethylene:polyoxypropylene ether in the macromonomer is 1:1.5:3.

[0022] The preparation process is as follows:

[0023] Step 1: Dissolve the weighed macromonomer in 1 part of water to obtain aqueous solution A, and dissolve acrylic acid, sodium methacrylate sulfonate, 2-hydroxyethyl methacrylate phosphate and silane-modified graphene in 2 parts Aqueous solution B was obtained in water, and ammonium persulfate was dissolved in 1 part of water to obtain aqueous solution C;

[0024] Step 2: Add aqueous solution A, aqueous solution B and aqueous solution C in sequence in a container equipped with...

Embodiment 2

[0029] The raw materials of the following mass components were selected: 1 part of macromonomer, 0.235 parts of acrylic acid, 0.1 part of sodium methacrylate sulfonate, 0.027 parts of 2-hydroxyethyl methacrylate phosphate, 0.0035 parts of silane-modified graphene, and 0.0002 parts of ammonium sulfate, 0.00015 parts of neutralizing agent, 5 parts of water, and the ratio of isopentenyl:polyoxyethylene:polyoxypropylene ether in the macromonomer is 1:1.5:3.

[0030] The preparation process is as follows:

[0031] Step 1: Dissolve the weighed macromonomer in 1.5 parts of water to obtain aqueous solution A, and dissolve acrylic acid, sodium methacrylate sulfonate, 2-hydroxyethyl methacrylate phosphate and silane-modified graphene in 1 part Aqueous solution B was obtained in water, and ammonium persulfate was dissolved in 2.5 parts of water to obtain aqueous solution C;

[0032] Step 2: Add aqueous solution A, aqueous solution B and aqueous solution C in sequence in a container equi...

Embodiment 3

[0037] A low-air-entraining and retarding-setting polycarboxylate water reducer, which consists of the following ingredients in parts by weight: 0.5 parts of macromonomer, 0.3 parts of acrylic acid, 0.05 parts of sodium methacrylate, 2-hydroxyethyl methacrylic acid 0.035 parts of ester phosphate, 0.002 parts of silane-modified graphene, 0.0002 parts of ammonium persulfate, 0.0002 parts of neutralizing agent, and 6 parts of water.

[0038] The isopentenyl group in the macromonomer: polyoxyethylene: polyoxypropylene ether is 1:1.8:2.5.

[0039] The preparation method of the described low air-entraining retarding polycarboxylate water reducer comprises the following steps:

[0040]Step 1: According to the ratio, extract the raw materials, dissolve the macromonomer in water to obtain aqueous solution A, mix acrylic acid, sodium methacrylate sulfonate, 2-hydroxyethyl methacrylate phosphate and silane-modified graphite Alkene is dissolved in water to obtain aqueous solution B, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com