Amphiphilic porous cyclodextrin polymer

A porous polymer, cyclodextrin technology, applied in the field of environmental protection materials, can solve the problems of low density, limited application, poor wettability, etc., and achieve the effects of high adsorption rate, enhanced hydrophilicity, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

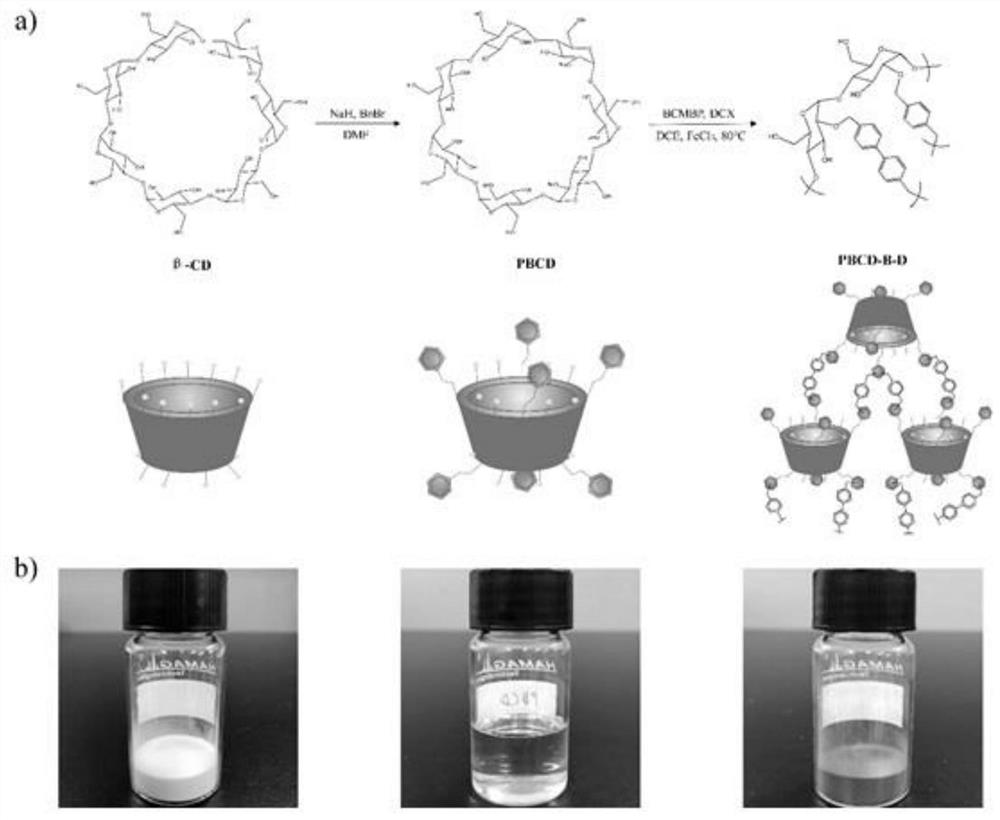

[0051] Preparation of Porous Cyclodextrin Polymer:

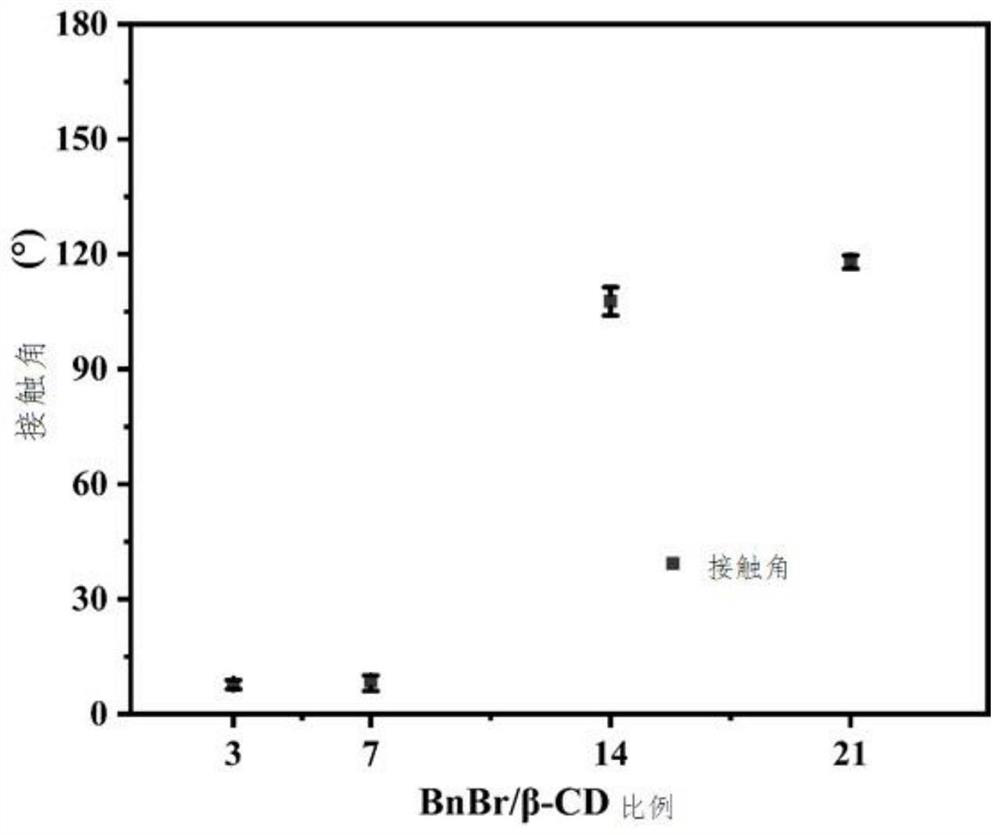

[0052] Dissolve the cyclodextrin and cool it in an ice-water bath; add sodium hydride and stir evenly; slowly drop in the benzylation reagent and react overnight to obtain the benzylated cyclodextrin. The molar ratio of benzylation reagent to cyclodextrin is shown in the summary table of the examples below. Then the benzylated cyclodextrin and the alkylating agent are catalyzed by Lewis acid, under the protection of nitrogen, in an oil bath equipped with magnetic stirring, react at a certain speed and temperature for a certain period of time. The molar ratio of alkylating agent to benzylated cyclodextrin is 5–8:1. The temperature is usually 55-100°C, preferably 75-90°C. The reaction time is preferably 15-30h, preferably 19-25h, most preferably 19h. If it is not within the above-mentioned preferred range, incomplete reaction and low yield will occur. The obtained product is washed several times with distilled water and me...

Embodiment 2

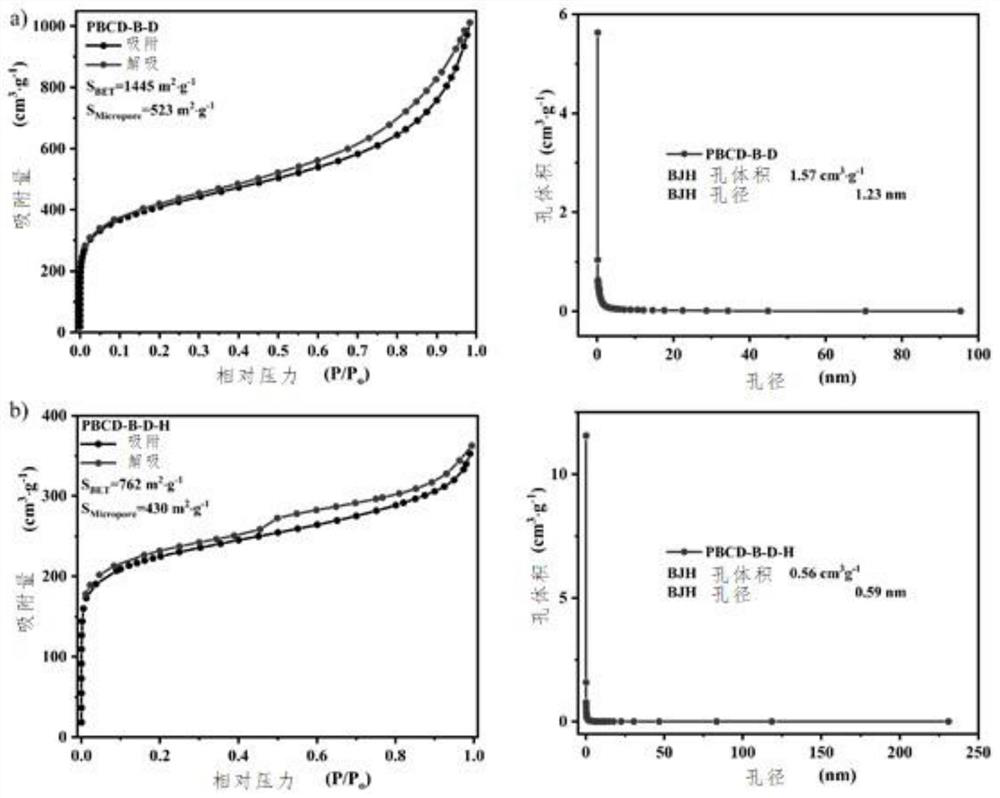

[0091] Preparation of high specific surface cyclodextrin polymer PBCD-B-D-H by sulfuric acid route:

[0092] a. Preparation of partially benzylated cyclodextrin PBCD

[0093] 1) In a round bottom flask, dissolve 2g of β-cyclodextrin in 40mL of anhydrous dimethylformamide, cool to 0°C in a low-temperature constant temperature reaction bath, add 0.59g of 60% sodium hydride, and stir for 15min;

[0094] 2) Slowly drop 0.8 mL of benzyl bromide into the solution with a constant pressure funnel, heat to room temperature, and stir overnight;

[0095] 3) After reacting overnight, add 5 mL of methanol to quench the reaction;

[0096] 4) Add 100 mL of distilled water, and extract three times with dichloromethane, 50 mL each time. The obtained solution was dried and filtered with anhydrous sodium sulfate, and concentrated at 35° C. with a rotary evaporator to obtain partially benzylated cyclodextrin PBCD.

[0097] b. Preparation of PBCD-B-D-H

[0098] 1) Take 1.06g of PBCD, 0.82g of ...

Embodiment 3

[0107] In order to fully illustrate the material properties of the amphiphilic high specific surface cyclodextrin polymer PBCD-B-D prepared in Example 1, activated carbon GAC and non-porous cyclodextrin polymer EPI-CDP were used as comparison materials, and different water-soluble Four kinds of model pollutants (3-phenylphenol, 2-naphthol, p-nitrophenol, p-chlorophenol) are carried out adsorption experiment, concrete method is as follows:

[0108] The adsorbents used were all ground into powder (60-80 mesh) before use. The sample taken was filtered with an Agilent 0.22 μm PTFE-Q filter membrane (almost no adsorption to the above pollutants). The concentrations of different pollutants in the water samples were then determined by high performance liquid chromatography (HPLC). The chromatographic column adopts Agilent XDB-C18 analytical column (5 μm, 4.6×250 mm), and the detector is an ultraviolet detector.

[0109] The specific method for the determination of the adsorption is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com