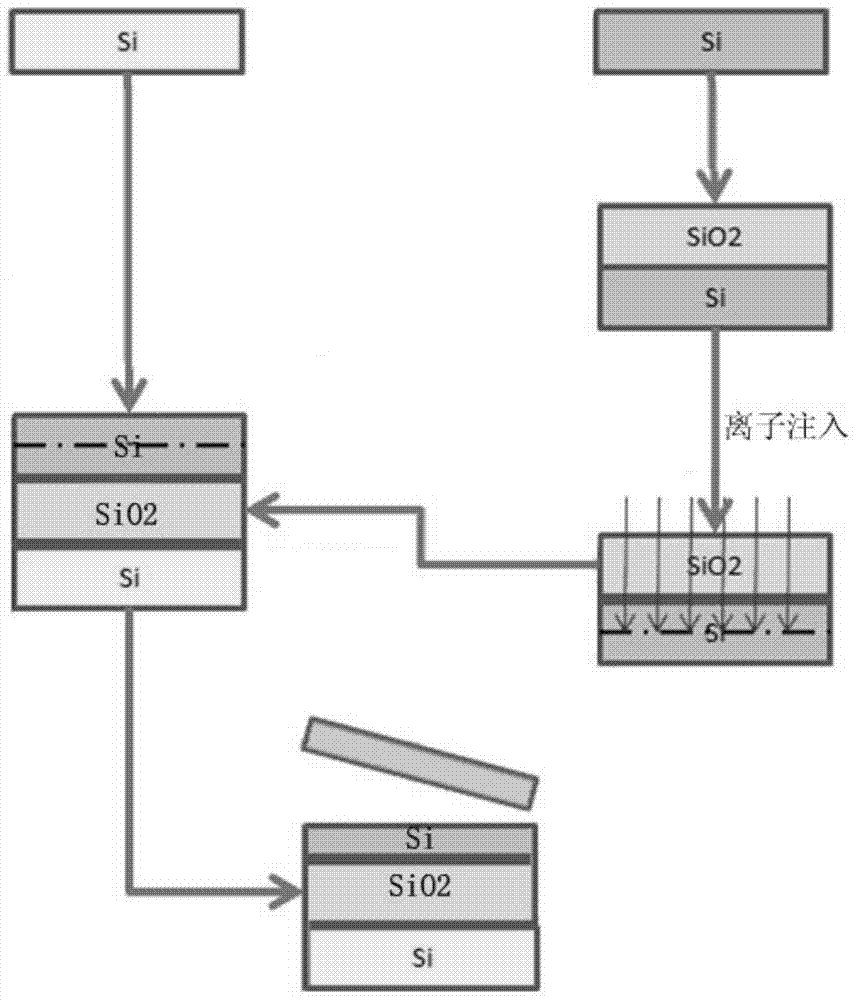

Method for preparing SOI silicon chip by means of laser chip breaking technology

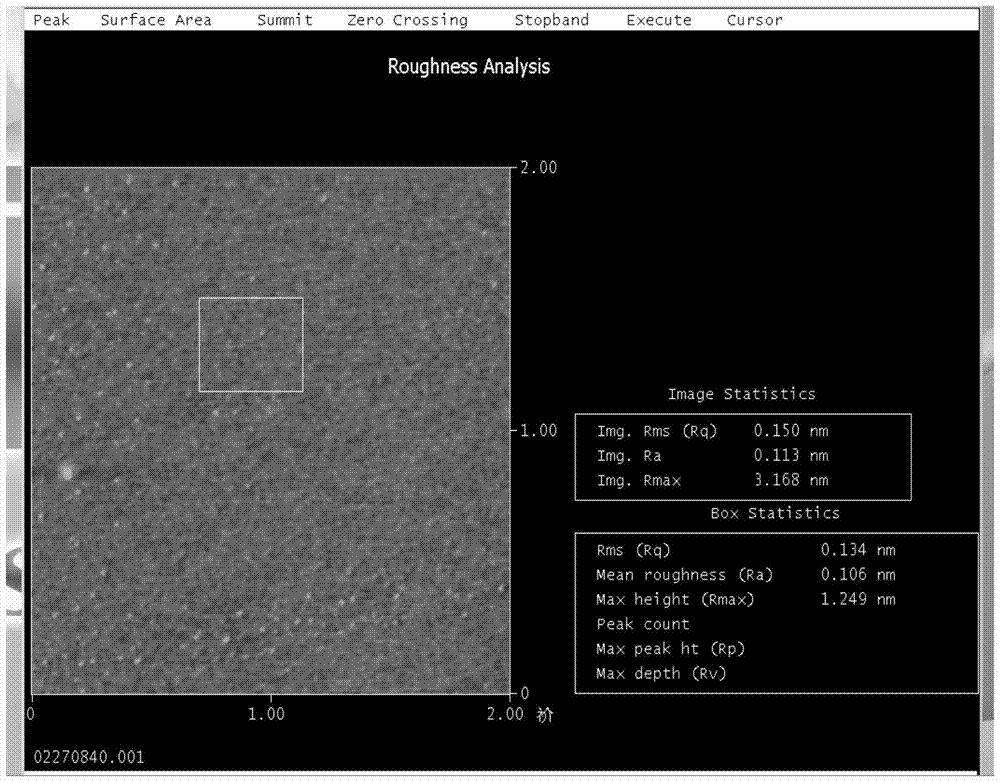

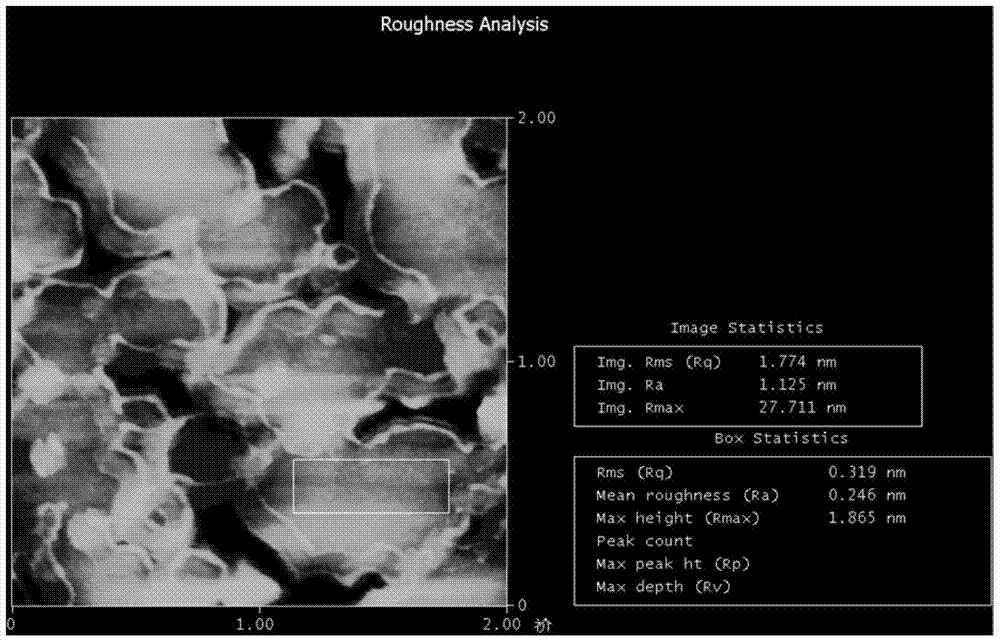

A technology of silicon wafers and splits, which is applied in the field of preparing SOI silicon wafers by using laser splitting technology, which can solve the problems that the temperature cannot be controlled and adjusted, and cannot be industrialized, so as to eliminate lattice defects, improve surface roughness, and remove surface adsorption substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Take an 8-inch P-type silicon wafer, its crystal orientation can be selected from or , and its resistivity can be selected from light doping to high resistance.

[0025] 2. Preparation of oxide layer (silicon dioxide) on the silicon wafer: oxidize one surface of the silicon wafer in step 1 (or both wafers can be oxidized, according to the actual process conditions) to obtain a silicon wafer with an oxide layer (Silicon dioxide is used as the BOX layer of SOI), the oxidation adopts a conventional process, and the thickness of the prepared oxide layer (silicon oxide) is >0-1000nm; the prepared silicon wafer with an oxide layer is cleaned with SC1 and SC2 in turn to remove the silicon wafer Surface contamination, and then use the test equipment to test the surface particles of the silicon wafer, use the test equipment to test the thickness of the silicon oxide and other parameters (such as the particles of the silicon oxide layer, electrical parameters), select the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com