Preparation method of 99.6 percent of Al2O3 ceramic substrate for thin film integrated circuit

A technology for ceramic substrates and integrated circuits, applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high cost, expensive equipment, complex technology, etc., achieve smooth surface, extremely thin and uniform thickness, softening high point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In view of the shortcomings of the existing alumina ceramic substrates in terms of performance and preparation technology, relevant researchers in the field of alumina ceramic substrates have conducted in-depth research on the surface treatment of substrates. In addition to polishing, there are also surface treatment methods. Coating method, coating technology mainly includes chemical vapor deposition (CVD), physical vapor deposition (PVD), thermal spraying method, screen printing method, sol-gel method, etc. With the development of modern ceramic glaze technology, glass glaze technology It has been applied to the preparation of insulating layers and the packaging of electronic devices. Glass glaze is a thin layer of uniform vitreous substance fused on the surface of the substrate. It has the characteristics of smooth and bright, high mechanical strength, stable chemical properties, and good matching with the substrate. There are very few reports on coating high-tempera...

Embodiment 1

[0081] (1) ingredients, mixing

[0082] Raw material according to 99.6% Al 2 o 3 -0.3%MgO-0.1%SiO 2 The mass ratio is carried out batching, and the mixed material that has weighed, agate ball, deionized water are put into the ball mill in the agate jar according to the ratio of 1:2:1 and mix;

[0083] Ball milling parameters are: 387rpm, 6h. After ball milling, pour out the slurry, put it in an oven at a constant temperature of 90°C for 48 hours, and pass through a 100-mesh screen;

[0084] (2) Configuration cast material

[0085] adding organic solvent ethanol and toluene, and binder PVB to the alumina powder obtained after drying and sieving to obtain a cast material;

[0086] (3) Casting and lamination

[0087] Using the tape casting method, the casting material is passed through the casting machine to obtain alumina green ceramic tape, the film thickness of which is 59±1μm, and then stacked, the number of layers is 9, and then isostatic pressing and cutting processes ...

Embodiment 2

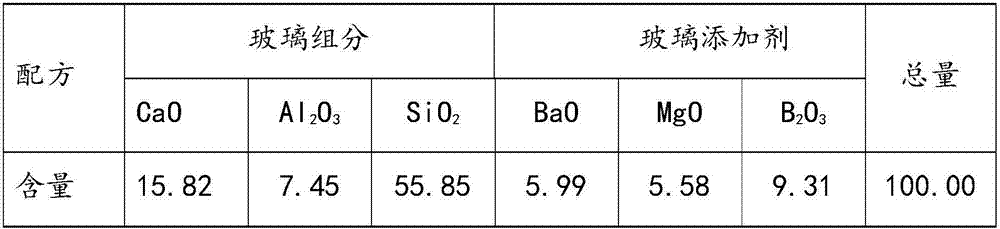

[0108] Change the composition of the glass: according to the basic formula, in CaO-Al 2 o 3 -SiO 2 Change the composition and content of additives in the glass phase formation interval, as shown in the following table:

[0109] Table 3 Modified glass formula design

[0110]

[0111] Then put the ingredients into the corundum crucible of the frit furnace, and melt in the high-temperature frit furnace to form glass. The melting temperature is changed to 1500°C, and the holding time is 1h. After melting, it was poured into deionized water for quenching treatment to obtain a colorless and transparent glass body. Prepare glass slurry after ball milling, and then evenly spin-coat the glass slurry on the surface of the substrate by means of glue homogenization, and then perform heat treatment. The heat treatment temperature is changed to 1250° C., and other process conditions remain unchanged.

[0112] The heat-treated substrate has a high surface finish and a mirror effect, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com