A kind of 25mn steel flange casting forming, quenching, tempering strengthening and toughening treatment method

A treatment method and strengthening and toughening technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of easy formation of Widmanstatten structure, toughness cannot be guaranteed, and material burning loss, etc., so as to prevent the number of recrystallized grains from increasing , avoid macro/micro crack phenomenon, good effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

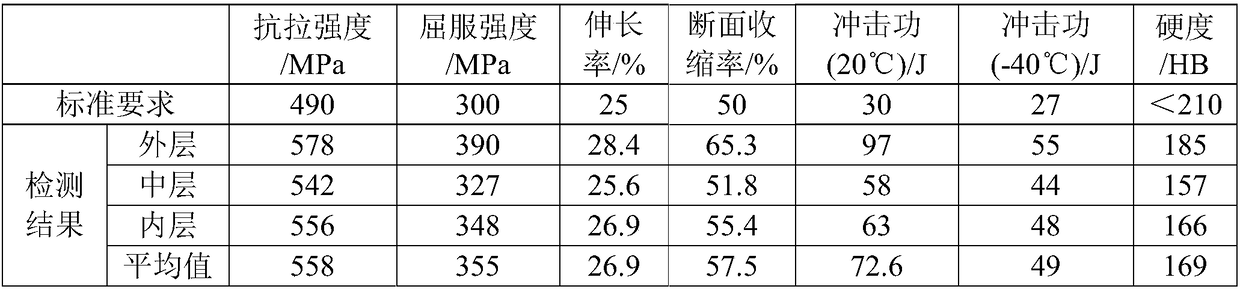

Examples

Embodiment Construction

[0012] Taking the 25Mn steel flange commonly used in wind power towers as a specific example, the size of the annular billet is the outer diameter D 0 =640mm, inner diameter d 0 =355mm, height H 0 = 160mm, the size of the hot rolled and expanded flange is outer diameter D = 1472mm, inner diameter d = 1300mm, height H = 95mm, and the casting and rolling forming, quenching and tempering strengthening and toughening treatment methods include the following process steps:

[0013] (1) Centrifugal casting: the casting temperature of the 25Mn steel annular billet is 1525°C, the mold speed is 230r / min, the preheating temperature of the mold, runner and ladle is 210°C, and the pouring speed is 28kg / s. Release the mold when the surface temperature of the slab drops to 1060°C;

[0014] (2) Return to the furnace for temperature supplementation: quickly return the centrifugally cast ring billet after being released from the mold at 1260°C for temperature supplementation, and the holding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com