Preparation method and application of carrier-free combined cross-linked glucose oxidase/catalase enzyme aggregation

A technology of glucose oxidase and catalase, applied in biochemical equipment and methods, oxidoreductase, immobilized enzyme, etc., can solve the problems of high cost of immobilization of carriers, low recovery rate of enzyme activity, etc., and achieve fine particle size , the effect of small mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of carrier-free co-immobilized glucose oxidase / catalase Combi-CLEAs (CAT / GOx) with bovine serum albumin (BSA) as protective agent:

[0039]Mix 1mLGOx with 1mLCAT, the enzyme activity ratio is 1:3; add 1mL BSA (0.5mg / mL) solution to the above mixed enzyme solution, mix well; then add 6mL isopropanol and 1mL glutaraldehyde (25%, v / v ), isopropanol as a precipitating agent, glutaraldehyde as a crosslinking agent, 4 ℃ constant temperature incubator 100rmp precipitation crosslinking 3h, add 200μL sodium cyanoborohydride solution (50mmol / L), continue to react for 30min and then mix the solution Centrifuge at 4°C and 8000rmp for 10min, discard the supernatant, and wash the pellet 5 times with phosphate buffer to obtain Combi-CLEAs (CAT / GOx), the recovery rate of enzyme activity is 127%, as figure 1 shown.

Embodiment 2

[0041] Preparation of carrier-free co-immobilized glucose oxidase / catalase Combi-CLEAs (CAT / GOx) with polylysine (EPL, mw3000) as protective agent:

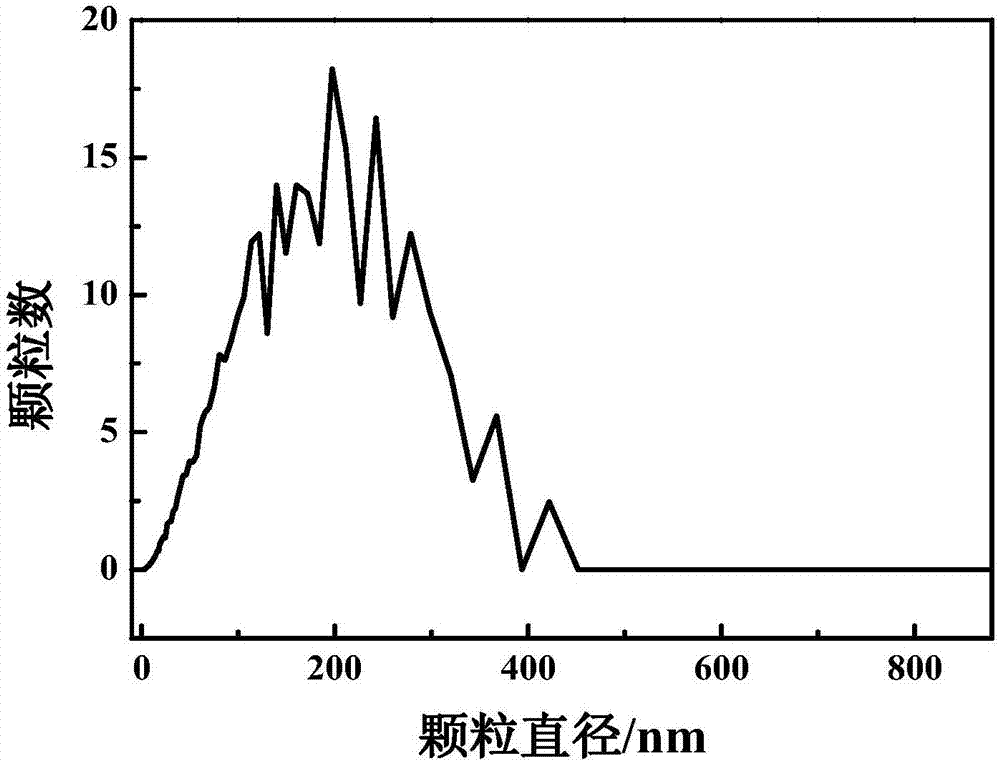

[0042] Mix 1mLGOx with 1mLCAT, the enzyme activity ratio is 1:5; add 1mL EPL (0.2mg / mL) solution to the above mixed enzyme solution, mix well; then add 6mL isopropanol as a precipitant and 1mLPEG-CHO (molecular weight 2000KDa, 0.5mg / mL), isopropanol as a precipitating agent, PEG-CHO as a crosslinking agent, 4 ℃ precipitation crosslinking for 3h, add 200μL sodium cyanoborohydride solution (50mmol / L), after 30min, centrifuge the mixed solution for 10min , the supernatant was discarded, and the precipitate was washed 5 times with phosphate buffer to obtain Combi-CLEAs (CAT / GOx), and the recovery rate of enzyme activity was 133%, as figure 1 shown. image 3 The particle size distribution diagram of the carrier-free co-immobilized glucose oxidase / catalase Combi-CLEAs (CAT / GOx) prepared by adding polylysine was detected by a particle ...

Embodiment 3

[0044] PEG-NH 2 (Molecular weight 6000) as the preparation of carrier-free co-immobilization glucose oxidase / catalase Combi-CLEAs (CAT / GOx) of protective agent:

[0045] Mix 1mLGOx with 1mLCAT, the enzyme activity ratio is 1:15; add 1mL PEG-NH to the above mixed enzyme solution 2 (0.2mg / mL) solution, mix well; then add 6mL absolute ethanol as precipitant and 1mL vanillin (1g / L), absolute ethanol as precipitant, vanillin as crosslinking agent, 4°C for precipitation and crosslinking for 3h Then add 200 μL of sodium cyanoborohydride solution (50 mmol / L), centrifuge the mixed solution for 10 min after 30 min, discard the supernatant, wash the precipitate 5 times with phosphate buffer to obtain Combi-CLEAs (CAT / GOx), and recover the enzyme activity rate of 100%, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com