Preparation method of graphene-chromium titanium aluminum composite material and application thereof to cutter

An aluminum composite material, graphene technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of improving comprehensive quality, small dilution rate, and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

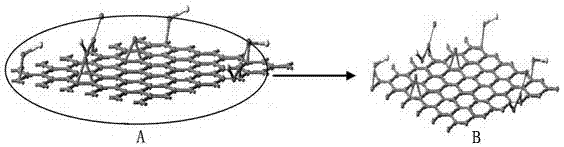

Image

Examples

preparation example Construction

[0032] The preparation method of graphene-chromium-titanium-aluminum composite material comprises the following steps: step 1, select nanometer graphene powder, and place it in the hydrofluoric acid aqueous solution that concentration is 1.6wt%, 60~80Hz ultrasonic wave, at 80 Stir at a speed of ~150r / min for 50~70min, let stand for 60~90min, pour out the upper layer solution and floating impurities, add deionized water to the obtained precipitate for washing, let stand for 60~90min and pour out the upper layer solution again, Add deionized water again and wash multiple times until the pH value of the upper layer solution is greater than 6.5 to obtain the graphene nano powder after pickling; the graphene nano powder after the acid washing is washed with absolute ethanol to obtain pretreated graphite Graphene nanopowder, spare; the average thickness of the selected nanographene powder is less than 3nm, the diameter of the sheet is 1~5μm, and the specific surface area is 40~60m 2...

Embodiment 1

[0047] The application of a graphene-chromium-titanium-aluminum composite material on cemented carbide-based cutting tools. Through laser beam radiation, it melts together with the surface material of the cutting tool and then solidifies rapidly, so that the dilution rate is small and the compatibility with the cutting tool material is good. The surface coating is actually a highly dense bonded graphene composite cladding layer, which organically combines the tool base material and the coating material. Thus, the comprehensive properties of the tool such as wear resistance, corrosion resistance, and oxidation resistance are significantly improved, and the purpose of tool surface repair or improvement is realized. The main preparation conditions are: refined graphene nano powder accounts for 5% of the total mass percentage, Ti powder accounts for 20% of the total mass percentage, Al powder accounts for 20 mass percentage, Cr powder accounts for 55% of the total mass percentage, ...

Embodiment 2

[0064] The application of a graphene-chromium-titanium-aluminum composite material on high-speed steel-based cutting tools. Through laser beam radiation, it melts together with the surface material of the cutting tool and then solidifies rapidly to obtain a low dilution rate and good compatibility with the cutting tool material. Surface coating, the surface coating is actually a highly dense bonded graphene composite cladding layer, which organically combines the tool base material and coating material. Thus, the comprehensive properties of the tool such as wear resistance, corrosion resistance, and oxidation resistance are significantly improved, and the purpose of tool surface repair or improvement is realized. The main preparation conditions are: refined graphene nano powder accounts for 10% of the total mass percentage, Ti powder accounts for 22% of the total mass percentage, Al powder accounts for 23% by mass, Cr powder accounts for 45% of the total mass percentage, laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com