Composite implant material and method of making the same

A technology for implanting materials and substrates, applied in the field of surgery, to achieve good corrosion resistance, excellent biocompatibility, and the effect of promoting repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

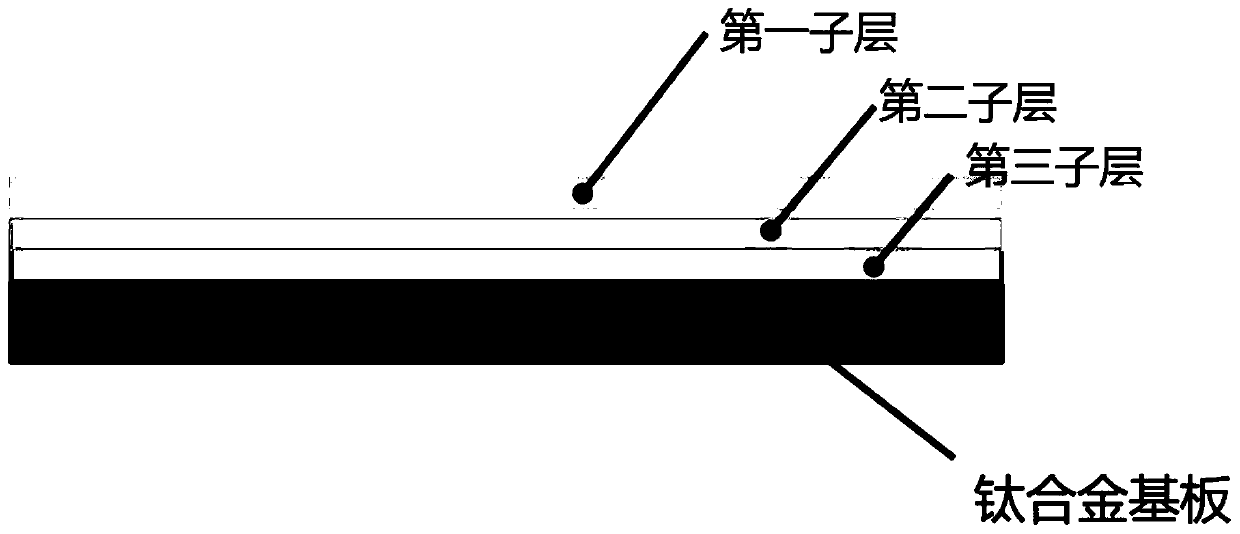

[0050] Example 1: Preparation of a composite implant material comprising three sublayers using spin coating

[0051] In this example use Figure 5 The steps shown in (a) specifically include the following steps:

[0052] 1) Preparation of TiO 2 , Al 2 o 3 , ZnO raw material solution;

[0053] ① Preparation method of ZnO raw material solution:

[0054] The reagents for preparing ZnO sol are: zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) as a precursor, absolute ethanol as a solvent, and monoethanolamine as a stabilizer, and all reagents used are of analytical grade.

[0055] The preparation process is: weigh quantitative (Zn(CH 3 COO) 2 2H 2 O) be dissolved in dehydrated alcohol, make the metal ion concentration in the solution be 0.45mol / L, add and Zn 2+ Equimolar amount of monoethanolamine, drop a small amount of glacial acetic acid at the same time, and stir fully at 70°C for 2 hours to obtain a light yellow transparent ZnO sol with stable performance (the conce...

Embodiment 2

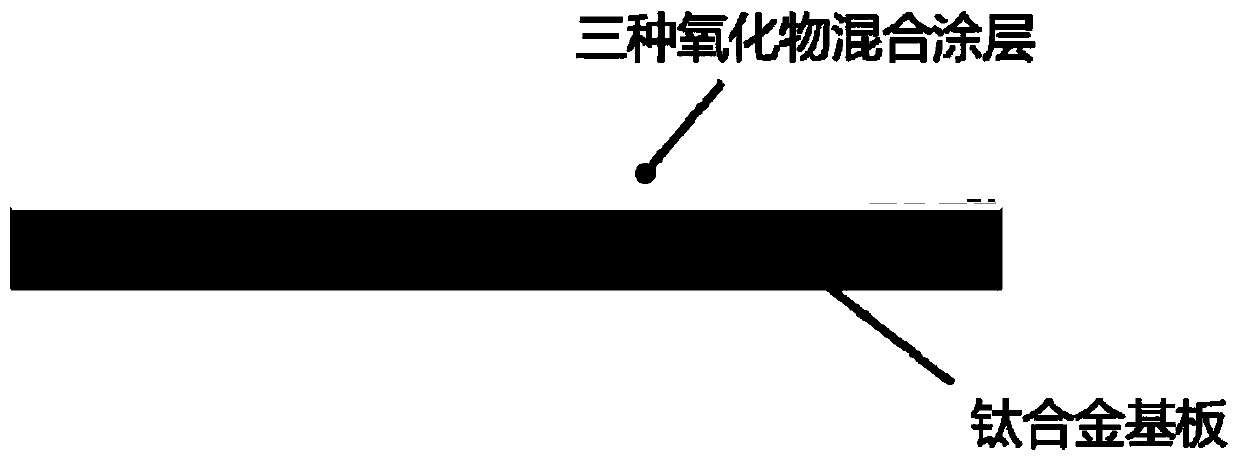

[0068] Example 2: Preparation of a composite implant material comprising a single coating using the spin-coating method

[0069] In this example use Figure 5 The steps shown in (b) specifically include the following steps:

[0070] 1) Preparation of TiO 2 / Al 2 o 3 / ZnO mixed solution (using tetrabutyl titanate, aluminum isopropoxide and zinc acetate dihydrate as precursors, absolute ethanol as solvent, and ethanolamine as stabilizer. The ratio of the three metal compounds in the mixed solution is converted to the corresponding metal The weight ratio of oxide can be expressed as: zinc oxide: titanium oxide: aluminum oxide=1:4:1.25);

[0071] 2) Cleaning the substrate: the first step is ultrasonic cleaning with acetone solution for 1.5 hours, the second step is ultrasonic cleaning with absolute ethanol solution for 1.5 hours, and finally the ultrasonic cleaning with deionized water for 1.5 hours. After cleaning, the substrate is stored in isopropanol solution.

[0072] 3)...

Embodiment 3

[0082] In this Example 3, the thermal insulation properties of the composite materials prepared in the above-mentioned Examples 1-2 and Comparative Examples 1-14 were characterized. Specifically, after irradiating the composite material sample with a high-frequency electromagnetic wave with a power of 25W and a frequency of 2450MHz for 10 minutes, the temperature increase of the sample surface was measured immediately compared with the surface temperature before irradiation. The results are summarized in Figure 6a and 6b .

[0083] From Figure 6a and 6b It can be seen that compared to the composite material containing three kinds of metal oxides described in the present invention, if any one or two oxides are omitted, even if the same amount of material is spin-coated (coated In the case that the basic thickness of the layer is the same), it will still cause a significant decrease in the thermal insulation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com