Ga2O3 material-based cap layer composite double-gate P-type metal-oxide-semiconductor field-effect transistor (PMOSFET) and preparation method thereof

A technology of composite double gate and capping layer, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems affecting the device performance of PMOSFET, insufficient hole transfer rate, Fermi pinning effect, etc., and achieve improvement Reliability, reduction of short channel effect, reduction of hot carrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

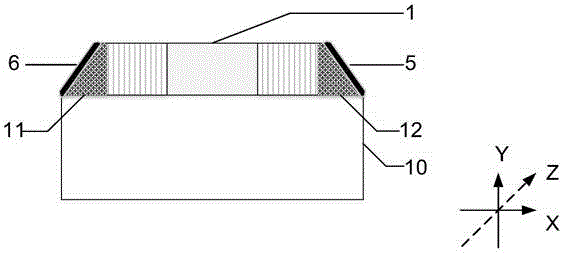

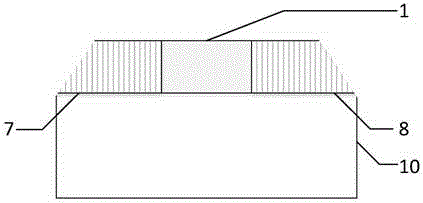

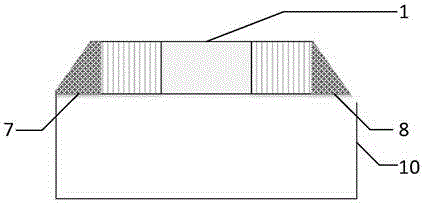

[0061] See figure 1 , figure 2 , image 3 and Figure 4 , figure 1 A Ga-based 2 o 3 The first cross-sectional schematic diagram of the cap layer compound double-gate PMOSFET of the material (taken along the plane formed by the XY axis); figure 2 A Ga-based 2 o 3 The second cross-sectional schematic diagram of the cap layer composite double-gate PMOSFET of the material (taken along the plane formed by the ZY axis, and the viewing angle is: the direction of the drain electrode → the source electrode); image 3 A Ga-based 2 o 3 The third cross-sectional schematic diagram of the cap layer composite double-gate PMOSFET of the material (taken along the plane formed by the ZY axis, and the viewing angle is: the direction of the source electrode → the drain electrode); Figure 4 A Ga-based 2 o 3 The schematic top view of the composite double-gate PMOSFET with the cap layer of the material. The cap layer composite double-gate PMOSFET includes a gallium oxide mesa 1, a co...

Embodiment 2

[0081] Please also see Figure 6a-Figure 6l , Figure 13a-Figure 13b , Figure 14a-Figure 14b , Figure 15a-Figure 15b , Figure 16a-Figure 16b , Figure 17a-Figure 17b and 18a- Figure 18b , Figure 13a-Figure 13b A schematic structural diagram of a first mask set provided by an embodiment of the present invention; Figure 14a-Figure 14b A schematic structural diagram of a second mask set provided by an embodiment of the present invention; Figure 15a-Figure 15b A schematic structural diagram of a third mask set provided by an embodiment of the present invention; Figure 16a-Figure 16b A schematic structural diagram of a fourth mask set provided by an embodiment of the present invention; Figure 17a-Figure 17b A schematic structural diagram of a fifth mask set provided by an embodiment of the present invention; and Figure 18a-Figure 18b A schematic structural diagram of a sixth mask set provided by an embodiment of the present invention. On the basis of the above-men...

Embodiment 3

[0101] See Figure 7 , Figure 8 , Figure 9 and Figure 10 , Figure 7 Another Ga-based 2 o 3 The first cross-sectional schematic diagram of the cap layer composite double-gate PMOSFET of the material; Figure 8 Another Ga-based 2 o 3 The second cross-sectional schematic diagram of the composite double-gate PMOSFET of the cap layer of the material; Figure 9 Another Ga-based 2 o 3 The third cross-sectional schematic diagram of the cap layer composite double-gate PMOSFET; Figure 10 Another Ga-based 2 o 3 The schematic top view of the composite double-gate PMOSFET with the cap layer of the material. The composite dual-gate NPMOSFET includes: a gallium oxide mesa 1, a composite gate dielectric layer composed of a gate oxide layer 2 near the source end region and a gate oxide layer 3 near the drain end region, a capping layer 4, a double metal gate electrode 9, a source drain It consists of heavily doped regions 7, 8, source and drain heavily doped regions 11, 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com