A kind of UV curable polyester and its preparation method and application

A polyester and catalyst technology, which is applied in the field of fine chemical synthesis, can solve the problems of high price, complex process, and high cost, and achieve the effects of strong anti-corrosion performance, simple process, and excellent medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

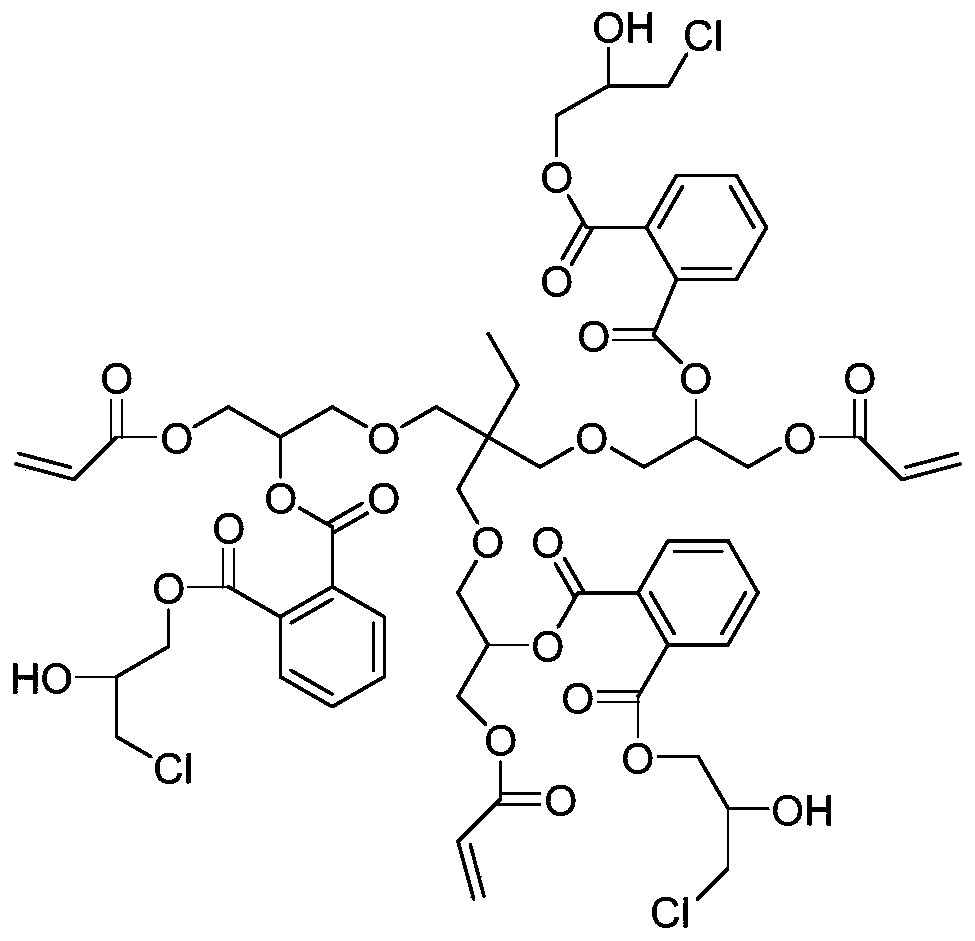

Image

Examples

Embodiment 1

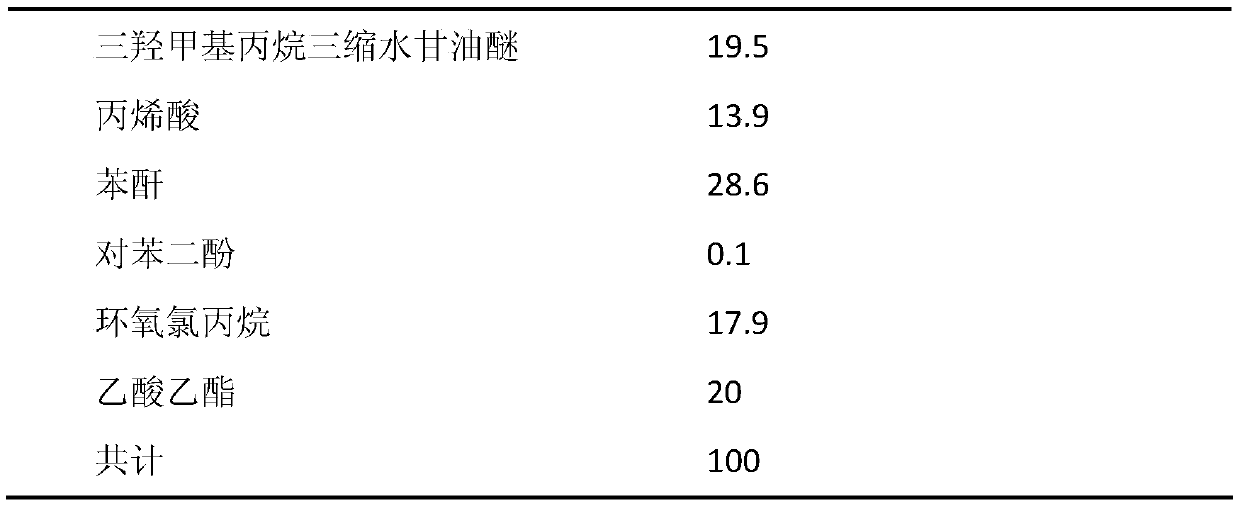

[0034] A kind of UV curable polyester acrylate, the composition of raw material formula mass percentage is as table 1 (excluding catalyzer):

[0035] Table 1

[0036]

[0037] (2) the preparation technology of this UV curing polyester acrylate comprises the following steps:

[0038] Mix trimethylolpropane triglycidyl ether, acrylic acid, hydroquinone, and ethyl acetate uniformly in the reactor according to the given mass, and add catalyst tetraethylammonium bromide (0.7% of triglycidyl ether mass ) at 120°C until the acid value is lower than 10mgKOH / g; add phthalic anhydride, hydroquinone and p-toluenesulfonic acid to the matrix prepared in step 1), react at 105°C for 2h, then add epichlorohydrin, and Add tetraethylammonium bromide (2% of the mass fraction of the epoxy compound) and ethyl acetate to react at 110°C until the acid value is less than 10mgKOH / g, distill under reduced pressure to remove the solvent, cool down and discharge the material, and obtain a UV-curable ...

Embodiment 2

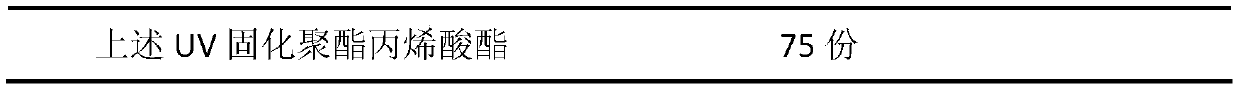

[0050] (1) A kind of UV curable polyester acrylate, the mass percentage composition of raw material formula is as shown in Table 4 (catalyst is not included):

[0051] Table 4

[0052]

[0053] (2) the preparation technology of this UV curing polyester acrylate comprises the following steps:

[0054] Mix trimethylolpropane triglycidyl ether, acrylic acid, tert-butylcatechol, and butyl acetate uniformly in the reaction kettle according to a given mass, and add catalyst tetrabutylammonium bromide (0.8% of the mass of triglycidyl ether) %) at 105°C until the acid value is lower than 10mgKOH / g; add hexahydroanhydride, hydroquinone and p-toluenesulfonic acid to the matrix prepared in step 1), react at 120°C for 2h, and add butyl glycidol Ether, and add catalyst p-toluenesulfonic acid and tetrabutylammonium bromide (3% of epoxy compound mass fraction) and butyl acetate to react at 120 ℃ until the acid value is less than 10mgKOH / g, cool down and discharge, and obtain UV curing P...

Embodiment 3

[0064] (1) A kind of UV curable polyester acrylate, the mass percentage composition of raw material formula is as shown in Table 7 (catalyst is not included):

[0065] Table 7

[0066]

[0067] (2) the preparation technology of this UV curing polyester acrylate comprises the following steps:

[0068] Mix trimethylolethane triglycidyl ether, itaconic acid, tert-butyl catechol, and propylene glycol methyl ether acetate according to a given mass and mix them uniformly in the reaction kettle, and add the catalyst hexadecyl ammonium bromide (trisharyl ammonium bromide) 1.0% of the glycerol ether mass) at 115°C until the acid value is lower than 10mgKOH / g; add succinic anhydride, tert-butylcatechol and p-toluenesulfonic acid to the matrix prepared in step 1), and react at 110°C for 3h , add butyl glycidyl ether, and add catalyst p-toluenesulfonic acid and tetrabutylammonium bromide (4% of epoxy compound mass fraction) and propylene glycol methyl ether acetate to react at 130 ℃ u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com