Preparation method of biological carbon fertilizer and application in passivating heavy metal in soil

A biochar and heavy metal technology, applied in the field of chemical fertilizers, can solve the problems of overuse, weakened passivation of heavy metals, short validity period, etc., and achieve the effect of not easy to leaching, reduce bioavailability, and long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

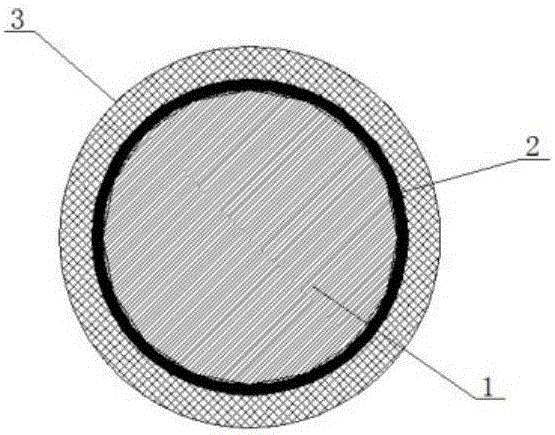

Image

Examples

preparation example Construction

[0022] A preparation method of biochar fertilizer, characterized in that: comprising the following steps

[0023] Step 1: Prepare 50-80 parts of biochar, 12-35 parts of nitric acid, and 3-10 parts of ammonia water according to the ratio of parts by weight. First, put the biochar into the reactor filled with nitric acid or put the Spray nitric acid onto biochar, and then add or spray ammonia water on the reaction product of biochar and nitric acid to obtain reaction product A. On the basis of extensive research on the compound process of biochar and ammonium nitrate, the raw material for ammonium nitrate synthesis was discovered The biochar-based nitrogen fertilizer produced by the chemical reaction process on biochar has excellent controlled release performance, which increases the nutrient validity period of ammonium nitrate, coordinates with the nutrient absorption during the growth and growth period of crops, and reduces its nutrient leaching loss and denitrification loss. ...

Embodiment 1

[0034] Step 1: Prepare 50 parts of biochar, 12 parts of nitric acid, and 3 parts of ammonia water according to the ratio of parts by weight. First, put the biochar into the reactor containing nitric acid or spray the nitric acid onto the biochar in the equipment containing the biochar Then add or spray ammonia water on the reaction product of biochar and nitric acid to obtain reaction product A.

[0035] Step 2: 40 parts of reaction product A, 20 parts of phosphate fertilizer, 0.5 part of nitrogen-fixing bacteria, 15 parts of vegetable vinegar liquid, 6 parts of waste molasses, and 1 part of fertilizer additive in parts by weight, and the fertilizer additive consists of the following parts by weight Component raw materials are mixed: 0.02 part of sodium nitrophenolate, 0.5 part of amino acid powder, 0.1 part of seaweed powder, 1 part of potassium citrate, 0.1 part of cobalt sulfide, 0.1 part of auxin, put into the mixer, 200rpm, 10min, Stir well to mix.

[0036] Step 3: Evenl...

Embodiment 2

[0041] Prepare 65 parts of biochar, 20 parts of nitric acid, and 7 parts of ammoniacal liquor in parts by weight, first put biochar into a reactor filled with nitric acid or spray nitric acid onto the biochar in the equipment holding biochar, and then Add or spray ammonia water on the reaction product of biochar and nitric acid to obtain reaction product A.

[0042] Step 2: 50 parts of reaction product A, 28 parts of phosphate fertilizer, 0.8 part of nitrogen-fixing bacteria, 25 parts of vegetable vinegar liquid, 8 parts of waste molasses, and 1.5 parts of fertilizer additive are prepared in parts by weight, and the fertilizer additive consists of the following parts by weight Component raw materials are mixed: 0.03 parts of sodium nitrophenolate, 1 part of amino acid powder, 0.6 parts of seaweed powder, 1.5 parts of potassium citrate, 0.4 parts of cobalt sulfide, 0.2 parts of auxin, put into the mixer, 200rpm, 10min, Stir well to mix.

[0043] Step 3: Evenly send the stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com