A kind of ultrasonic-assisted method for preparing nickel-cerium solid solution material

An ultrasonic-assisted, solid solution technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of low doping efficiency, affecting the overall performance of the catalyst, and uneven distribution of crystal phases, achieving high doping efficiency, Uniform crystal phase and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

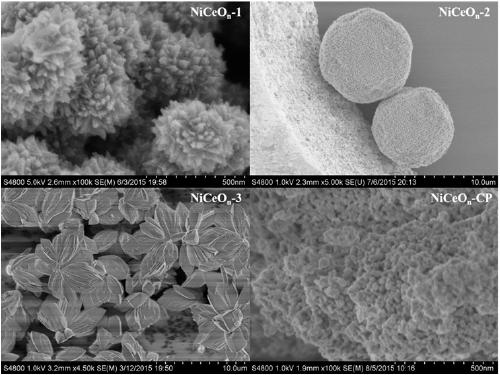

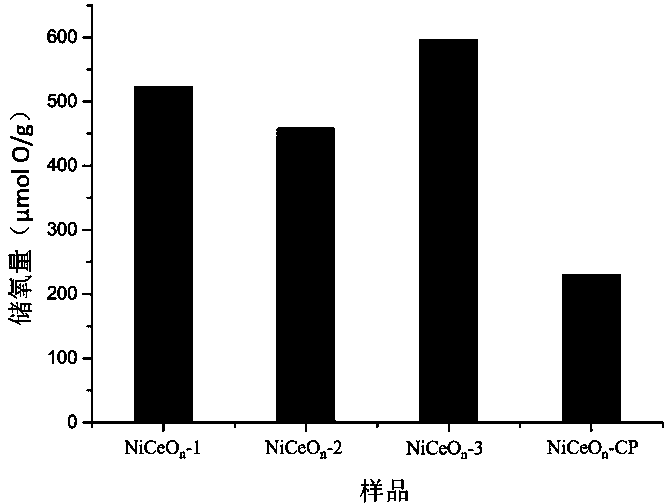

Embodiment 1

[0021] Add 0.181g cerium chloride heptahydrate and 0.029g nickel chloride hexahydrate (4:1 molar ratio) into a beaker containing 40ml dimethyl sulfoxide, and add 1.0ml formic acid, stir for 30min, put the beaker 1.0 g of polyvinylpyrrolidone (molecular weight: 10,000) was slowly added into the ultrasonic cleaning machine with a frequency of 40 kHz, and the ultrasonic temperature was set to 30°C, and the ultrasonic treatment was started for 0.5 h. Add 4ml of dilute ammonia water with a concentration of 1.5wt% and stir evenly, then transfer the solution to a hydrothermal kettle equipped with a polytetrafluoroethylene liner for high-temperature treatment at a temperature of 120°C and a treatment time of 0.5h. After the high-temperature treatment, filter the solution, wash the solid three times with distilled water and absolute ethanol, and then dry it at 80°C for 6-8h, then roast the solid at 400°C in an air atmosphere for 5h, with a heating rate of 2°C / min . Gained solid is soa...

Embodiment 2

[0023] Add 2.321g of cerium nitrate hexahydrate and 0.016g of nickel nitrate hexahydrate (99:1 molar ratio) into a beaker containing 100ml of dimethyl sulfoxide, and add 3.0ml of glycolic acid. After stirring for 30min, put the beaker into At the same time, slowly add 4.0 g of hexadecyl ammonium bromide to an ultrasonic cleaning machine with a frequency of 40 kHz, set the ultrasonic temperature to 60° C., and start ultrasonic treatment for 4 hours. Add 8ml of dilute ammonia water with a concentration of 3wt% and stir evenly, then transfer the solution to a hydrothermal kettle equipped with a polytetrafluoroethylene liner for high-temperature treatment at a temperature of 180°C and a treatment time of 72 hours. After the high-temperature treatment, filter the solution, wash the solid three times with distilled water and absolute ethanol, and then dry it at 80°C for 6-8h, then roast the solid at 600°C in an air atmosphere for 3h, with a heating rate of 3°C / min . Gained solid is...

Embodiment 3

[0025] Add 0.181g of cerium chloride heptahydrate and 0.013g of nickel chloride hexahydrate (9:1 molar ratio) into a beaker containing 34ml of dimethyl sulfoxide, and add 1.0ml of formic acid. After stirring for 30min, put the beaker 1.0 g of polyvinylpyrrolidone (molecular weight: 30,000) was slowly added into the ultrasonic cleaning machine with a frequency of 40 kHz, and the ultrasonic temperature was set to 30°C, and the ultrasonic treatment was started for 1 hour. Add 2ml of dilute ammonia water with a concentration of 2wt% and stir evenly, then transfer the solution to a hydrothermal kettle equipped with a polytetrafluoroethylene liner for high-temperature treatment at a temperature of 160°C for 4 hours. After the high-temperature treatment, filter the solution, wash the solid three times with distilled water and absolute ethanol, and then dry it at 80°C for 6-8h, then roast the solid at 450°C in an air atmosphere for 4h, with a heating rate of 2°C / min . Gained solid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com