Continuous extrusion die for aluminum pipes

An extrusion die and aluminum tube technology, applied in the field of aluminum tube continuous extrusion die, can solve the problems of weak adhesion between the wear-resistant layer and the substrate, weak adhesion between the wear-resistant layer and the substrate, and short life of the mold. Achieve the effect of small grain size, good dimensional stability and good red hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides an aluminum tube extrusion molding die, which specifically includes a male die, a female die and a forming mandrel 3 arranged on the male die.

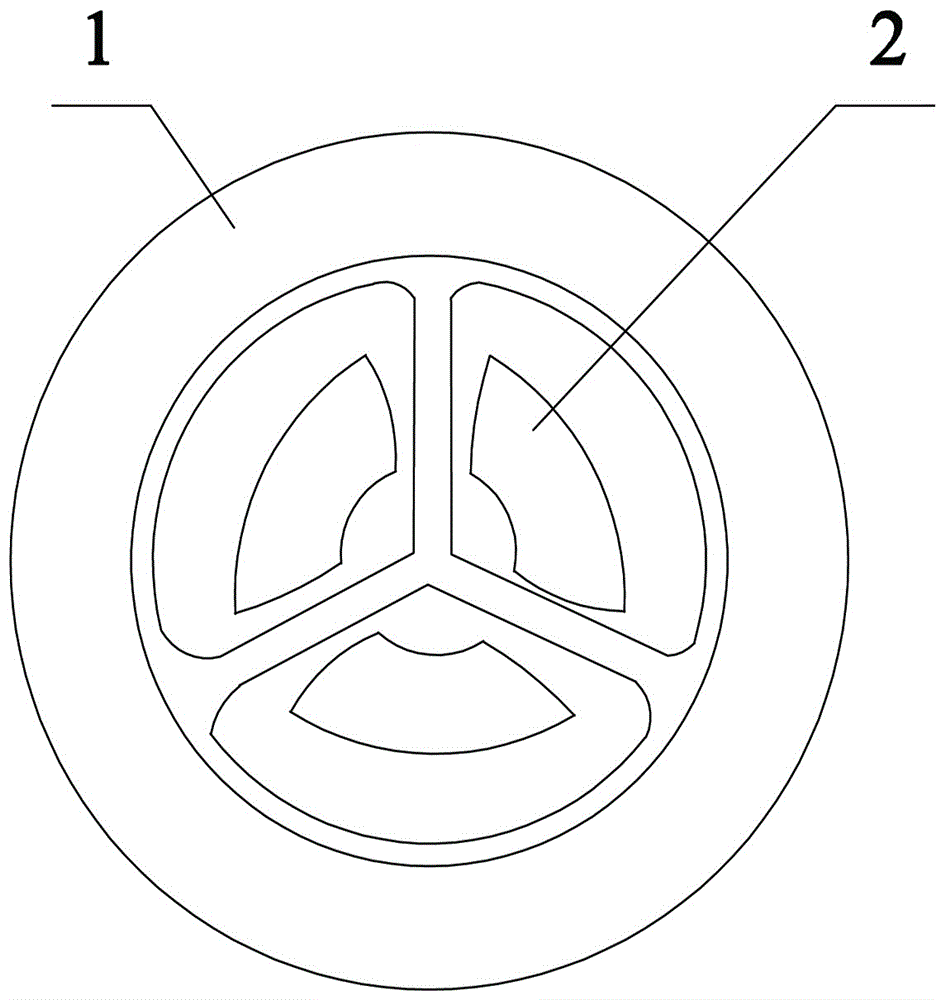

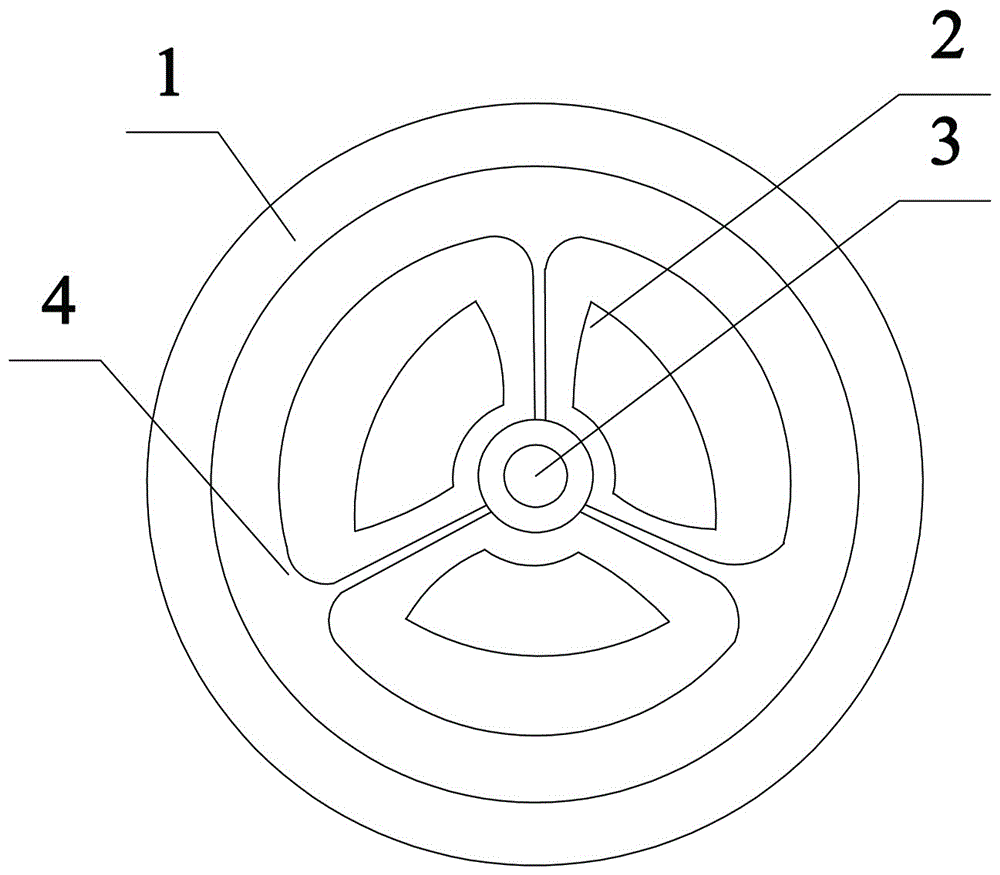

[0045] Such as figure 1 and figure 2 As shown, the punch includes a cylindrical punch base 1 , a punch forming boss 4 and three distribution grooves 2 passing through the punch forming boss 4 and the punch base 1 . Wherein the cylindrical punch base 1 and the punch forming boss 4 are integrated, and the center of the outer end surface of the punch forming boss 4 is provided with an assembly blind hole.

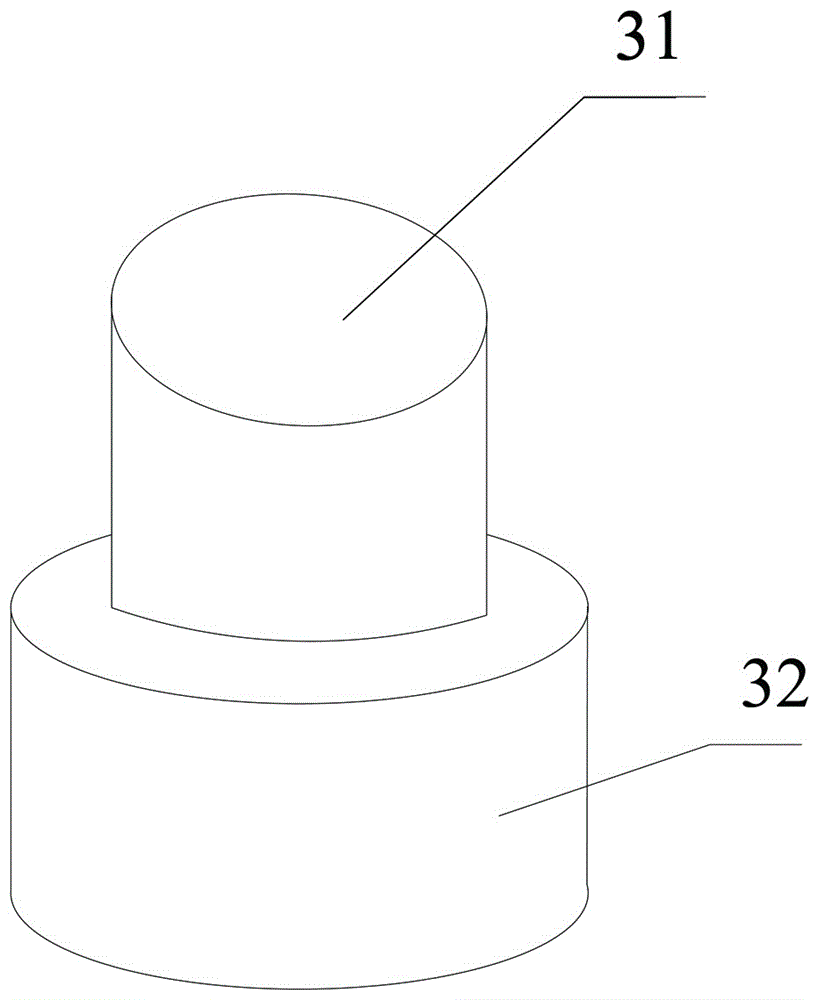

[0046] Such as image 3 and Figure 4 As shown, the forming mandrel 3 includes a forming mandrel base 34 and a wear-resistant and corrosion-resistant coating 35 deposited on the surface of the forming mandrel base 34 . Wherein, the wear-resistant and corrosion-resistant coating 35 is a nano-titanium nitride coating, and the thickness of the nano-titanium nitride coating is 5 microns. The forming m...

Embodiment 2

[0062] This embodiment provides a continuous extrusion die for aluminum tubes. The specific structure differs from that in Embodiment 1 in that:

[0063] The thickness of the wear-resistant and corrosion-resistant coating is 10 microns, and the thickness of the formed gasket 8 is 3 millimeters; the wear-resistant and corrosion-resistant coating is a nano-titanium carbide layer; the forming mandrel substrate and the forming The base of the gasket is processed from cemented carbide materials including the following mass percentage components: WC 85%, TiC 5%, Co 10%.

Embodiment 3

[0065] This embodiment provides a continuous extrusion die for aluminum tubes, the specific structure of which is roughly the same as that in Embodiment 1, except that:

[0066] The thickness of the wear-resistant and corrosion-resistant coating is 8 microns, the thickness of the formed gasket is 8 mm, and the wear-resistant and corrosion-resistant coating is a nano-titanium carbonitride layer; the forming mandrel base and the The formed gasket base is processed from cemented carbide materials including the following mass percentage components: WC 82%, TiC 6%, Co 8%, TaC 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com