A kind of lithium ion cathode material with surface coating metal nitride and preparation method thereof

A positive electrode material and surface coating technology, which is applied in the field of lithium ion positive electrode material coated with nitride on the surface and its preparation, to achieve the effects of stable material structure, uniform coating layer and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

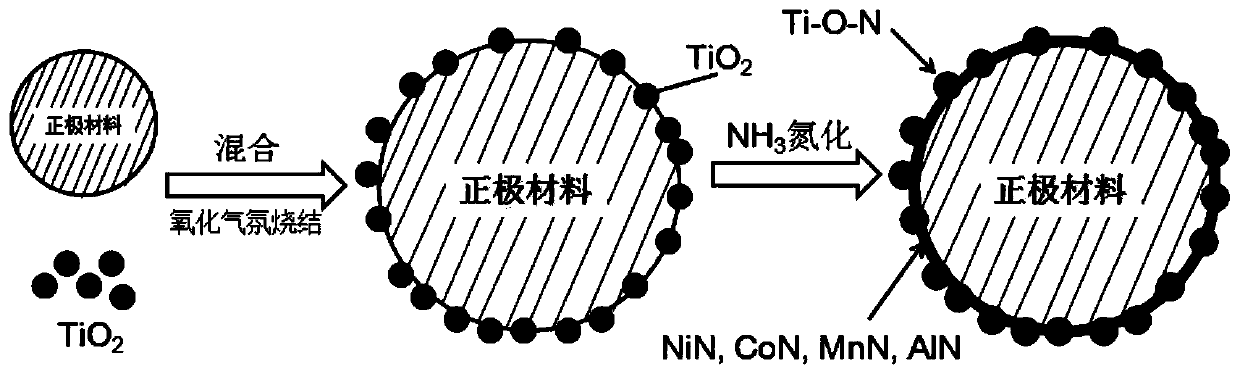

Method used

Image

Examples

Embodiment 1

[0033] Metal nitride coated Li(Ni 0.8 co 0.1 mn 0.1 )O 2

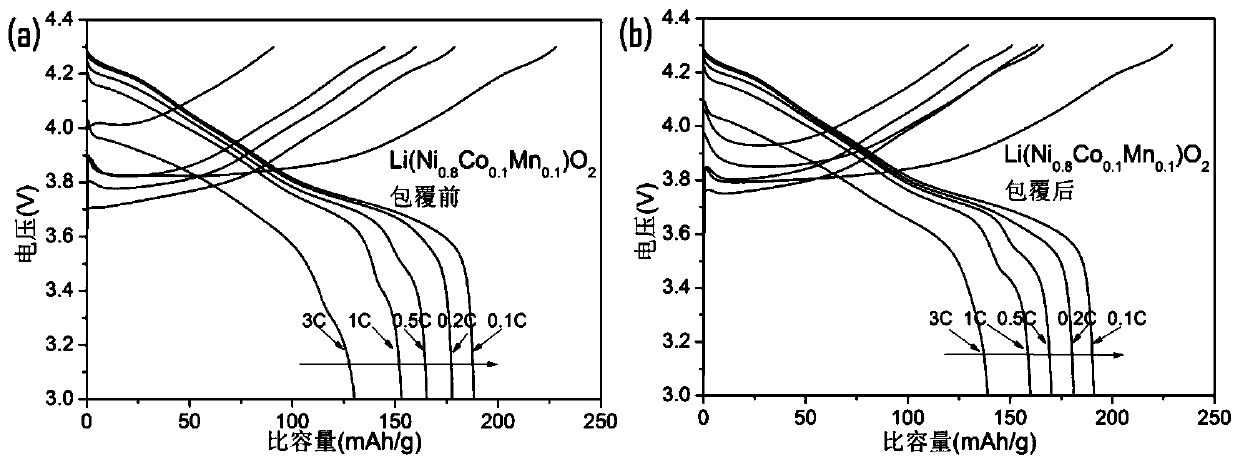

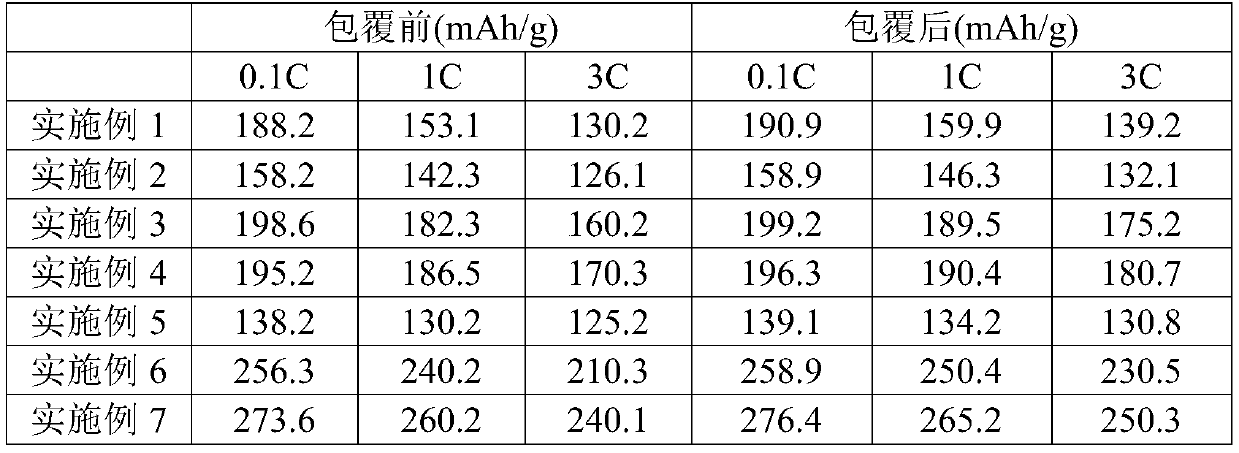

[0034] Take 20g Li(Ni 0.8 co 0.1 mn 0.1 )O 2 and 0.2gTiO 2 (Addition amount 1wt.%) After ball milling and mixing, put the powder in a tube-type atmosphere furnace, ventilate the air atmosphere, heat to 500°C for 3 hours, switch to nitrogen to replace the air, ventilate for 0.5 hours, and then switch to ammonia atmosphere , holding for 1.5h to obtain NiN, MnN, CoN and Ti-O-N metal nitride coated Li(Ni 0.8 co 0.1 mn 0.1 )O 2 . The electrochemical properties of the materials are listed in Table 1. The half-cell performance results of materials before and after coating are as follows: figure 2 shown. Before coating, the 0.1C capacity of the material reaches 188.2mAh / g. After coating, the 0.1C capacity of the material reached 190.9mAh / g; in terms of rate, the capacity of the coated material at 3C reached 139.2mAh / g, higher than the 130.2mAh / g before modification, and the rate performance was significantly i...

Embodiment 2

[0036] Metal nitride coated Li(Ni 0.5 co 0.2 mn 0.3 )O 2

[0037] Take 20g Li(Ni 0.8 co 0.1 mn 0.1 )O 2 and 0.1gTiO 2(addition amount 0.05wt.%) After ball milling and mixing, put the powder in a tube-type atmosphere furnace, ventilate the air atmosphere, heat to 500 ° C for 3 hours, switch to argon to replace the air, ventilate for 0.5 hours, and then switch to ammonia gas atmosphere, holding for 0.5h to obtain NiN, MnN, CoN and Ti-O-N metal nitride-coated Li(Ni 0.5 co 0.2 mn 0.3 )O 2 . The electrochemical properties of the materials are listed in Table 1.

Embodiment 3

[0039] Metal nitride coated Li(Ni 0.85 co 0.1 al 0.05 )O 2

[0040] Take 20g Li(Ni 0.85 co 0.1 al 0.05 )O 2 and 0.4gTiO 2 (Addition amount 2wt.%) After high-speed stirring and mixing, place the powder in a tube-type atmosphere furnace, ventilate the air atmosphere, heat to 600 ° C for 2 hours, switch to nitrogen to replace the air, ventilate for 1 hour, and then switch to ammonia atmosphere , holding for 1.5h to obtain NiN, AlN, CoN and Ti-O-N metal nitride coated Li(Ni 0.85 co 0.1 al 0.05 )O 2 . The electrochemical properties of the materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com