A kind of lithium-sulfur battery positive electrode and its manufacturing method

A lithium-sulfur battery and cathode technology, which is applied to the lithium-sulfur battery cathode and its manufacturing field, can solve problems such as affecting electrode reaction, increasing ion transmission resistance, internal self-discharge, etc., so as to shorten the ion transmission path, improve the charge conductivity, improve Effects of interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

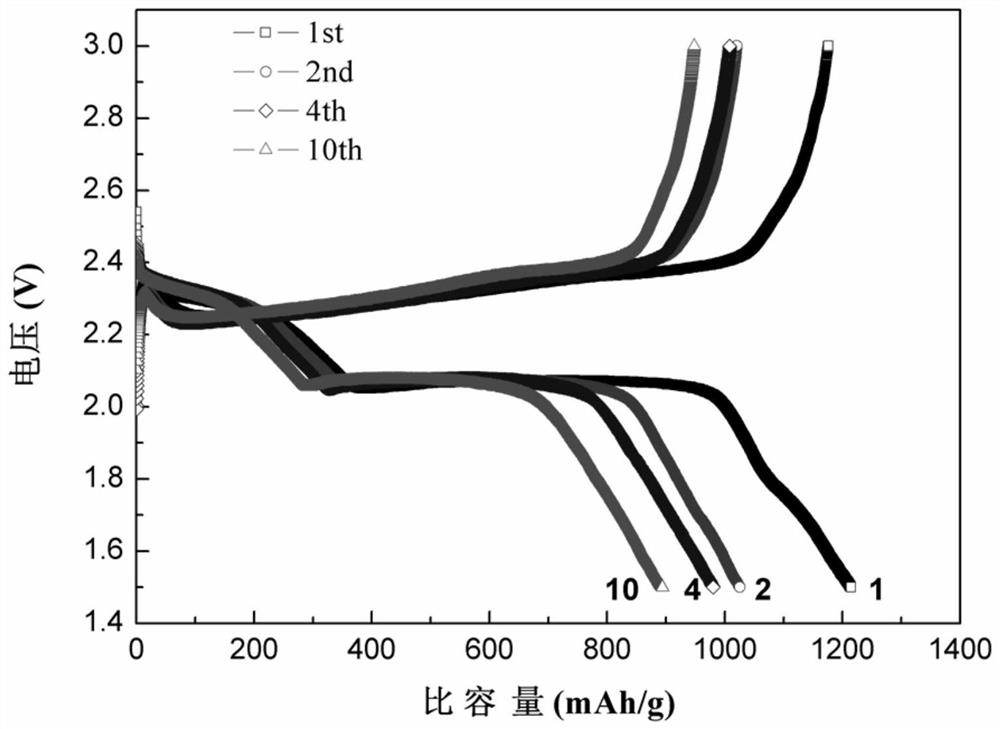

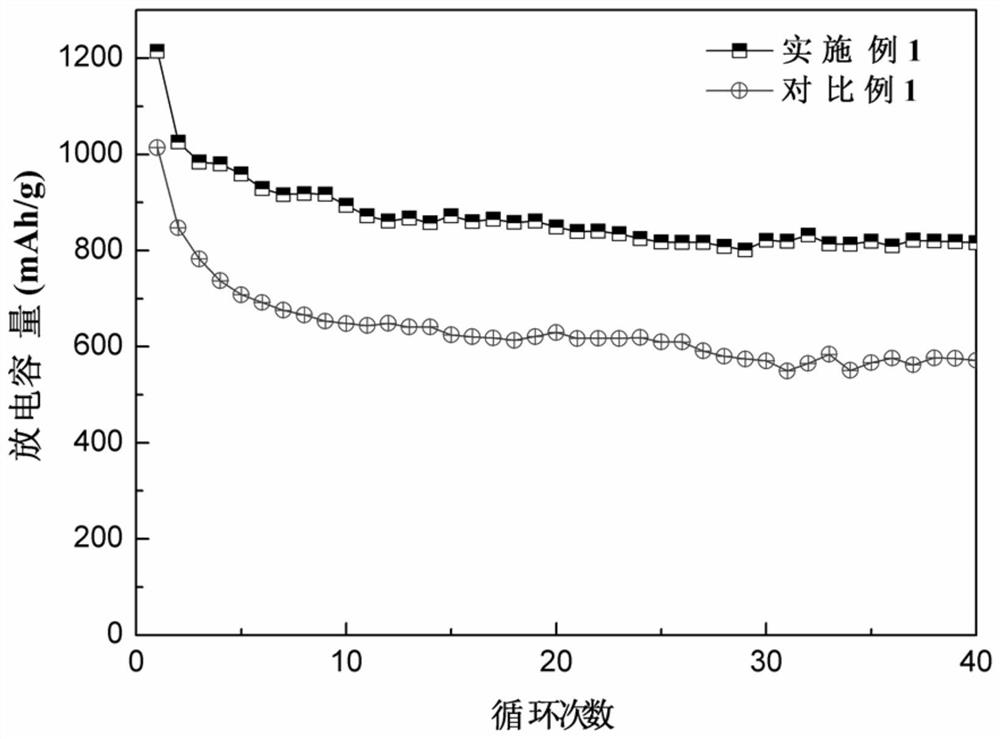

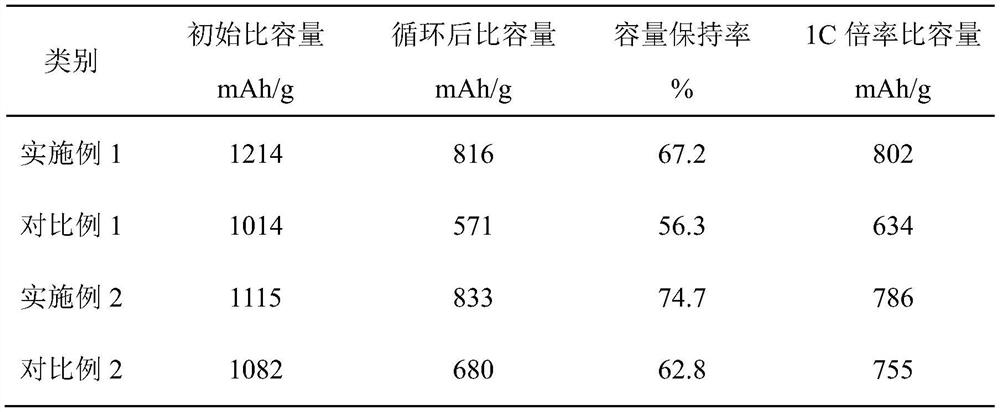

Embodiment 1

[0043] The sulfur-carbon composite material, conductive agent and binder were mixed in NMP at a mass ratio of 8:1:1, coated on an aluminum foil, and vacuum-dried at 50° C. for 48 hours to obtain a sulfur-containing active material layer.

[0044] Mix PVDF-HFP, PVP, and nano-carbon black in DMF solvent at a mass ratio of 10:4:1, and coat it on the above-mentioned sulfur-containing active material layer with a thickness of about 50um, and let it stand in the air for 2h. Then vacuum-dry at 50° C. for 48 hours to obtain a composite film layer.

[0045] In the glove box, soak the composite film layer in the electrolyte at 25°C for 12h (the electrolyte composition is 1mol / L LiTFSI and 0.1mol / L LiFSI dissolved in a mixed solvent of DME and DOL with a volume ratio of 1:1) , to prepare a gel electrolyte layer and a lithium-sulfur battery positive electrode carrying the gel electrolyte layer.

[0046] In the glove box, the above-mentioned positive electrode, polypropylene separator and...

Embodiment 2

[0053] The sulfur-containing active material layer is the same as in Example 1.

[0054] Mix PEO, PEDOT / PSS in deionized water at a mass ratio of 5:1, and coat it on the sulfur-containing active material layer with a thickness of about 20um. After vacuum drying at 70°C for 24 hours, a composite film layer and a composite film layer are prepared. Membrane lithium-sulfur battery positive electrode.

[0055] In the glove box, the above-mentioned positive electrode, polypropylene separator and metal lithium sheet were stacked sequentially, and an appropriate amount of electrolyte was added dropwise on the surface of the positive electrode composite film layer and the surface of the separator (the electrolyte composition was 1mol / L LiBETI and 0.1mol / L LiNO 3 Dissolved in a mixed solvent of ionic liquid Py14TFSI and DOL with a volume ratio of 7:3), quickly sealed in a button case and assembled into a lithium-sulfur battery. The battery was further gelled at 80° C. for 0.5 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com