Manufacturing device of flexible printed laminate and method of manufacturing flexible printed laminate

A technology of flexible printing and manufacturing equipment, which is applied to the manufacturing equipment of flexible printing laminates and the field of manufacturing of flexible printing laminates, to achieve the effect of eliminating fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

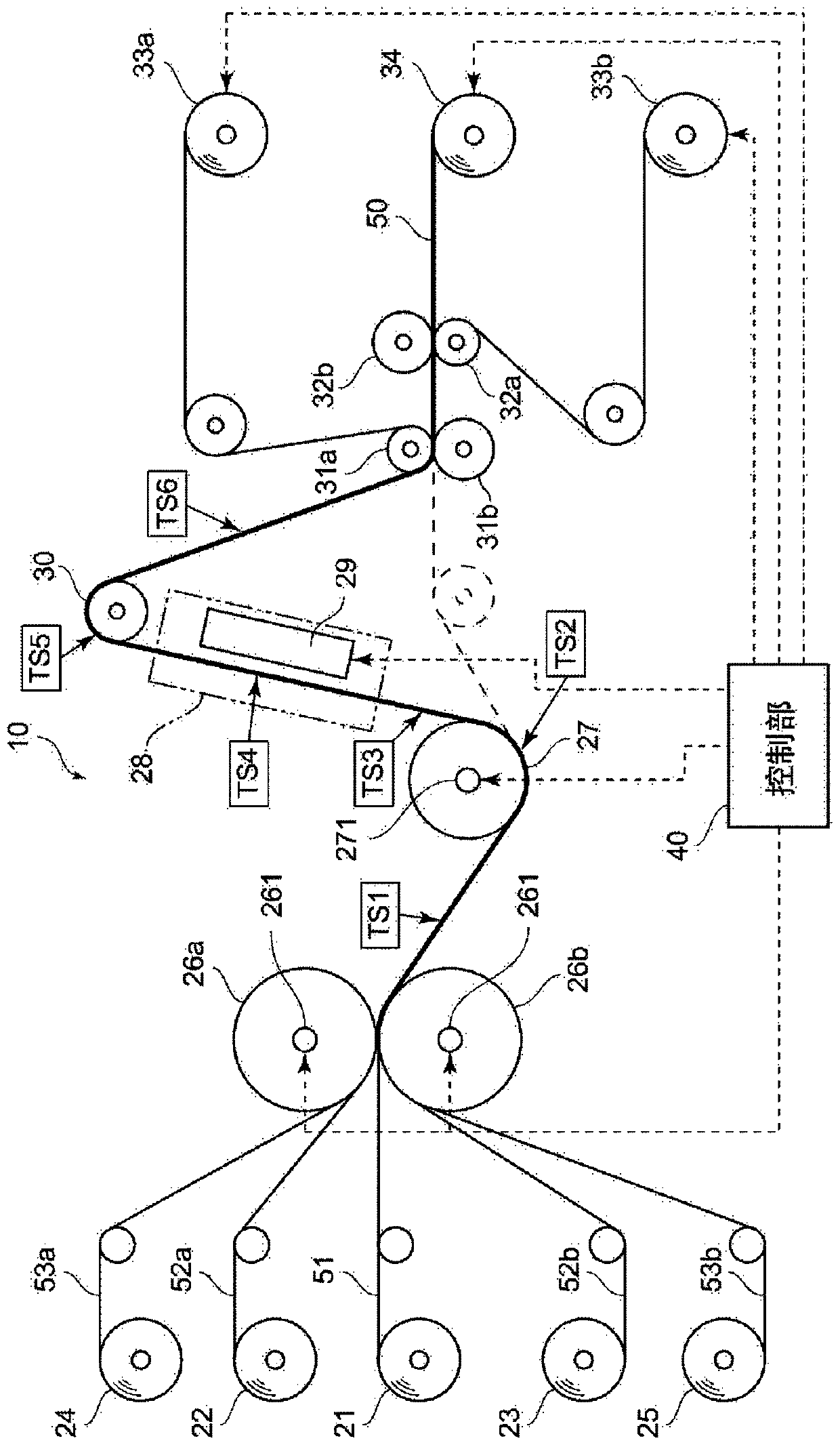

[0057] Hereinafter, the manufacturing apparatus 10 of the flexible printed laminated board 50 which concerns on one Embodiment of this invention is demonstrated based on drawing.

[0058]

[0059] figure 1 It is a schematic diagram of the manufacturing apparatus 10 (henceforth "manufacturing apparatus 10") of the flexible printed laminated board 50. The main components of this manufacturing device 10 include: supply rolls 21 to 25, a pair of lamination rolls 26a, 26b, a temperature adjustment roll 27, a temperature adjustment zone 28, a temperature adjustment device 29, an intermediate roll 30, a first peeling roll 31a, A first pass roll 31b, a second peeling roll 32a, a second pass roll 32b, film winding rolls 33a, 33b, a laminate winding roll 34, a control unit 40 for controlling the operations of the above components, And temperature sensors TS1~TS6 for measuring temperature.

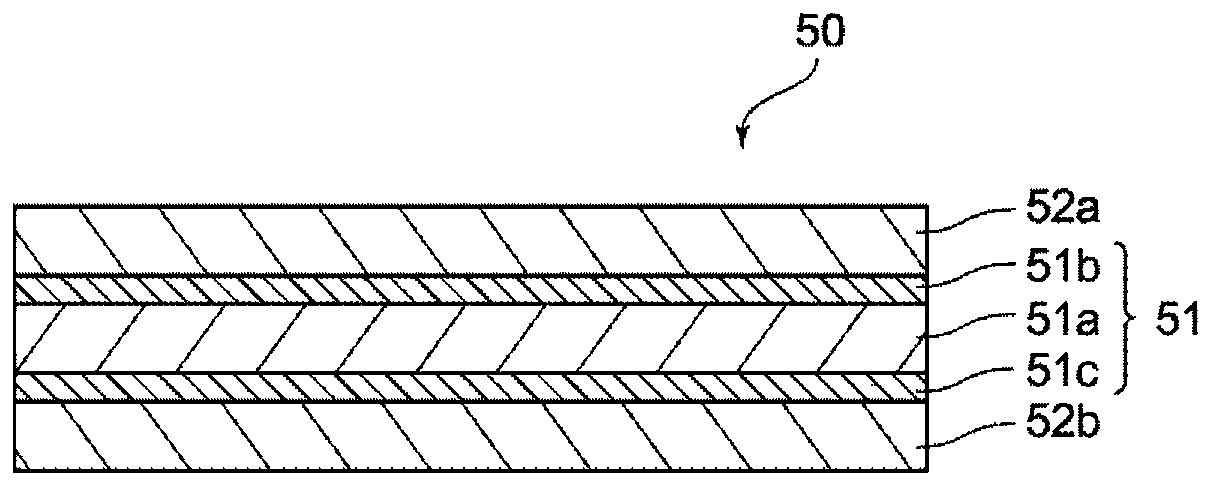

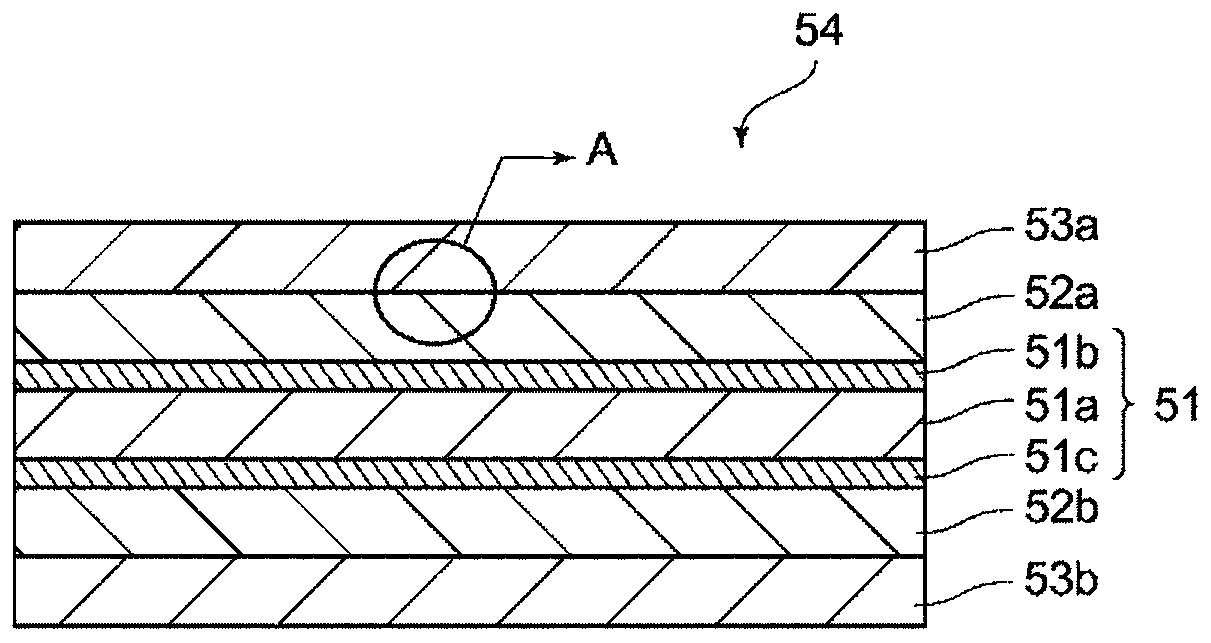

[0060] In this manufacturing apparatus 10, the base material 51, copper foil 52a, 52b, and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com