Quantum dot fiber gas sensor and preparation method thereof

A gas sensor and quantum dot technology, which is used in instruments, measuring devices, scientific instruments, etc., can solve the problems of low gas sensitivity of optical fiber gas sensors, and is suitable for remote sensing and networking, easy to array, and transmits a large amount of information. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

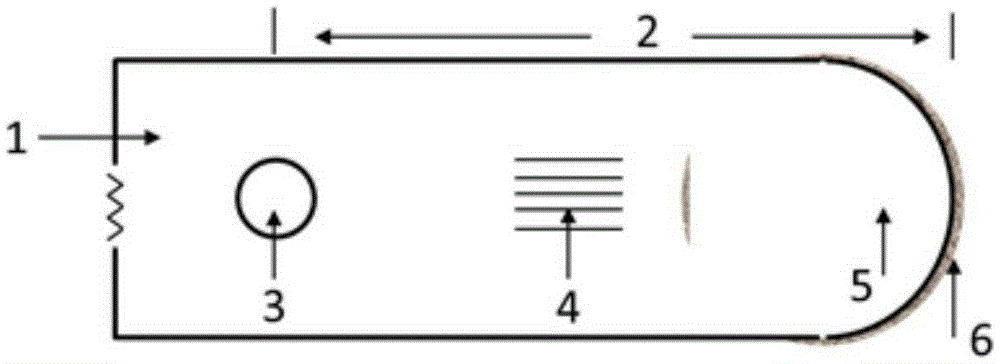

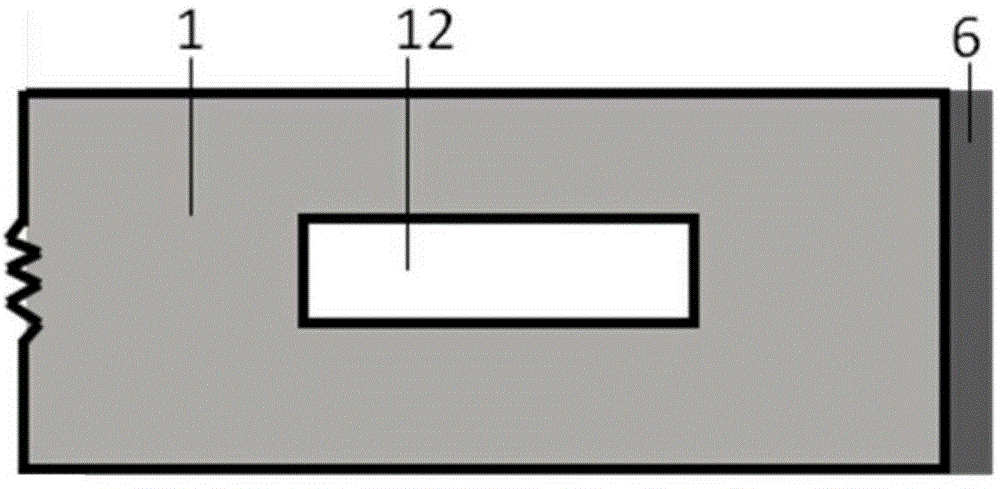

[0044] The structure of the quantum dot fiber optic gas sensor that embodiment 1 provides is as figure 1 As shown, it includes a fiber optic probe and a gas-sensitive layer; the gas-sensitive layer is coated on the hemispherical end of the fiber-optic probe;

[0045] In Example 1, the optical fiber probe is composed of a single-mode optical fiber and a photonic crystal optical fiber; the fusion site has a fusion bubble with a radius of 10 μm to 30 μm, and inside the PCF, there is a photonic crystal with a length of 100 μm to 300 μm at a distance of 200 μm from the fusion bubble. Optical fiber air hole structure, the end of the optical fiber probe is a hemispherical fusion ball with a radius of 60 μm to 100 μm obtained by melting PCF; the total length of the optical fiber probe (from the fusion bubble to the end) is 400 μm to 700 μm; the fiber probe’s The spectrum is multi-beam interference, which changes with the change of the refractive index at the end of the fiber probe; in...

Embodiment 3

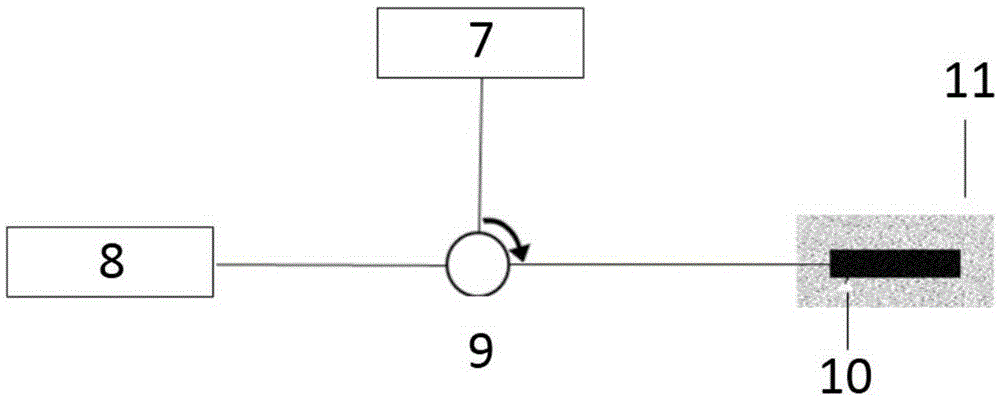

[0056] The optical fiber probe that adopts in embodiment 3, its structure is as Figure 4 As shown; the SMF is fused with the thin optical fiber, the length of the thin optical fiber is controlled to be 300 μm to 500 μm, and the Bragg grating (FBG) is etched on the thin optical fiber; the preparation process is as follows;

[0057] (1) Connect SMF and thin fiber (T-F);

[0058] (2) cutting the thin optical fiber part, and retaining the thin optical fiber with a length of 300 μm to 500 μm;

[0059] (3) Use a femtosecond laser to periodically etch the thin fiber according to the designed FBG parameters;

[0060] The optical fiber probe interference structure prepared by the above method can measure the refractive index change at the end of the FBG central wavelength.

[0061] The preparation method of the quantum dot fiber optic gas sensor provided by the present invention will be described in detail below in conjunction with specific examples.

Embodiment 4

[0062] The preparation method of the quantum dot fiber optic gas sensor provided by embodiment 4 comprises the steps:

[0063] (1) With lead oxide (PbO) as lead source, bistrimethylsilylsulfane (TMS) is as sulfur source, adopts colloid chemical method reaction to prepare PbS colloidal quantum dot solution;

[0064] Specifically, 0.9g (4mmol) PbO was dissolved in 3ml oleic acid (OA) and 17ml octadecene (ODE) under a nitrogen atmosphere and heated to 90°C to prepare the precursor of lead oleate as a lead source; After reaching 8 hours, the temperature of the precursor was raised to 120°C; 180ul (1mmol) TMS was dissolved in 10ml ODE as a sulfur source;

[0065] Inject the sulfur source into the lead source at 120°C. After the color of the reaction system turns black completely (about 15s), put the solution into cold water to quickly lower the temperature to room temperature; add acetone to the cooled solution, and remove it after centrifugal stirring. The supernatant is then dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com