Core-shell particle toughened PBT/PC alloy and preparation method

A particle, core-shell technology, applied in the field of PBT/PC alloy and its preparation, can solve the problems of high melt viscosity, poor solvent resistance, low low temperature impact strength, etc. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

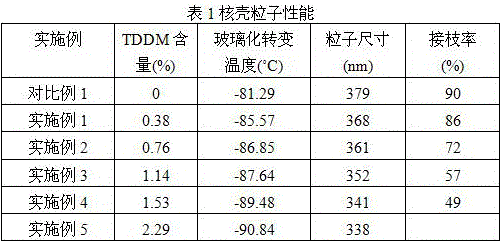

[0017] Example 1 A method for preparing a core-shell particle toughened PBT / PC alloy, (1) Take 753 g of polybutadiene latex with a solid content of 59.7% and add it to the reactor, add 2.25 g of sodium pyrophosphate, and 3.15 g of glucose , 0.045g ferrous sulfate, 1500mL deionized water, cumene peroxide (CHP), their mass ratio is 753:2.25:3.15:0.045:1500:0.28, nitrogen protection, the reaction temperature is 70 oC . Add dropwise the mixture of methyl methacrylate, styrene, cumene hydroperoxide and TDDM in the weight ratio of 110:331:1.125:1.72 to the reactor, after the addition is completed, add the mixture in the weight ratio of 9:0.28 Glycidyl methacrylate and cumene hydroperoxide, reacted for 1 hour, coagulated, washed, at 60 oC Under the condition of drying for 24 hours, the core-shell particle (PB-g-MSG) copolymer was obtained. The TDDM content of the core-shell particles prepared in Example 1 is 0.38%, and the properties are listed in Table 1.

[0018] (2) Put polycar...

Embodiment 2

[0021] Example 2 Methyl methacrylate, styrene, cumene hydroperoxide and TDDM were added dropwise into the reactor at a weight ratio of 110:331:1.125:3.44, and the rest were the same as in Example 1.

[0022] The TDDM content of the core-shell particles prepared in Example 2 is 0.76%, and the properties are listed in Table 1.

[0023] Step (2) and step (3) are the same as in Example 1.

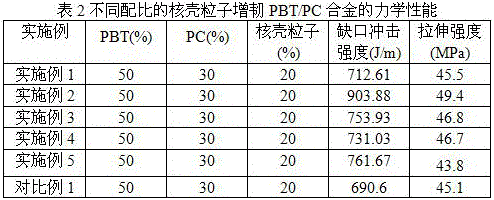

[0024] The prepared blend material was heated at 240 oC Injection into standard specimens for mechanical testing under conditions, and measure impact and tensile properties according to ASTM-D256 and ASTM-638 standards. The properties of the modified materials are shown in Table 2.

Embodiment 3

[0025] Example 3 Methyl methacrylate, styrene, cumene hydroperoxide and TDDM were added dropwise into the reactor at a weight ratio of 110:33:1.125:5.16, and the rest were the same as in Example 1.

[0026] The TDDM content of the core-shell particles prepared in Example 3 is 1.14%, and the properties are listed in Table 1.

[0027] Step (2) and step (3) are the same as in Example 1.

[0028] The prepared blend material was heated at 240 o Under the condition of C, it is injected into a mechanical test standard sample, and the impact and tensile properties are measured according to the ASTM-D256 and ASTM-638 standards. The properties of the modified materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com