Rust-proof and heat-resistant rapid curing type composite epoxy powder paint used for automobile chassis and preparing method thereof

A rapid curing, automotive chassis technology, applied in the direction of powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of limited use, high curing temperature, long curing time, etc., to improve heat resistance and rheology, film The effect of uniform layer performance and accelerated curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

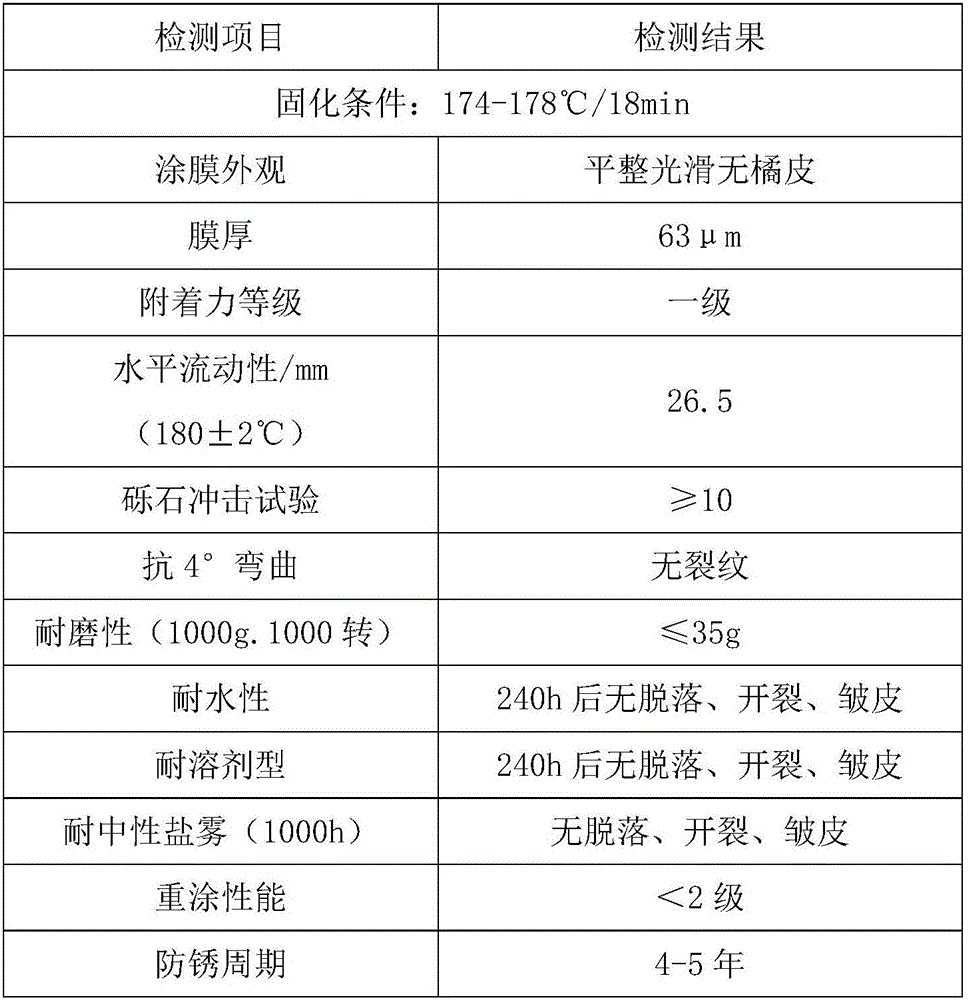

Image

Examples

Embodiment Construction

[0015] A kind of antirust and heat-resistant fast-curing composite epoxy powder coating for automobile chassis, the coating is made of the following raw materials in parts by weight: epoxy acrylic resin 15, bisphenol A epoxy resin 40, polybenzimidazole 4. N, N-dimethylformamide 25, metallocene catalyst 0.4, polyether amine D2000 2, phenolic curing agent 20, ethylene glycol butyl ether 3, aluminum tripolyphosphate / polymethyl methacrylate microspheres 10. Benzoin 1, antioxidant 0.5, brightener 0.4, sodium lauryl sulfate 0.1, deionized water 20.

[0016] Wherein the aluminum tripolyphosphate / polymethyl methacrylate microspheres are made of the following raw materials in parts by weight: aluminum tripolyphosphate 4, methyl methacrylate 5, divinylbenzene 2, dibenzoyl peroxide 0.4, Deionized water 20, absolute ethanol 12, sodium lauryl sulfate 0.1, the preparation method is:

[0017] (1) First put sodium lauryl sulfate into deionized water, stir until it is completely dissolved, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com