High-performance metallized film capacitor encapsulating material

A metallized film and potting material technology, which is applied in the field of capacitors, can solve the problems of toughness and plasticity, easy brittleness, high viscosity, internal stress, and poor temperature and impact resistance, and achieve high toughness and plasticity, no internal stress, and stable electrical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

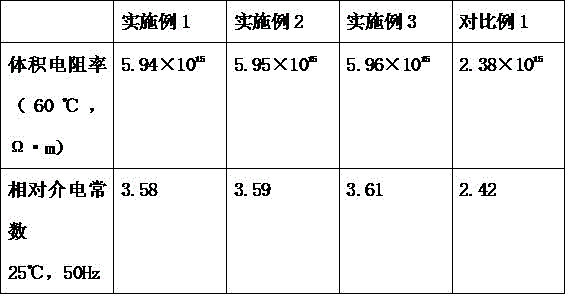

Embodiment 1

[0017] A high-performance potting material for metallized film capacitors, made of the following components in parts by weight: epoxy soybean oil 6, castor oil 15, polyisobutylene 20, modified salad oil 60, mica powder 16, glutamic acid 2 , polyvinyl alcohol resin 6, starch 6, soybean lecithin 3, latent curing agent 4, plasticizer 2, auxiliary agent 1; the auxiliary agent is made of the following ingredients in parts by weight: sodium polyacrylate 2, acetyl Methyl propionate 5, maltol 1; the mass ratio of the modified salad oil, polyisobutylene and latent curing agent is 15:5:1.

Embodiment 2

[0019] A high-performance potting material for metallized film capacitors, made of the following components in parts by weight: epoxy soybean oil 10, castor oil 18, polyisobutylene 30, modified salad oil 90, mica powder 19, glutamic acid 4 , polyvinyl alcohol resin 10, starch 8, soybean lecithin 5, latent curing agent 6, plasticizer 5, auxiliary agent 3; the auxiliary agent is made of the following ingredients in parts by weight: sodium polyacrylate 6, acetyl Methyl propionate 9, maltol 4; the mass ratio of the modified salad oil, polyisobutylene and latent curing agent is 15:5:1.

Embodiment 3

[0021] A high-performance potting material for metallized film capacitors, made of the following ingredients in parts by weight: epoxy soybean oil 4, castor oil 16, polyisobutylene 25, modified salad oil 75, mica powder 18, glutamic acid 3 , polyvinyl alcohol resin 7, starch 7, soybean lecithin 4, latent curing agent 5, plasticizer 3, auxiliary agent 2; the auxiliary agent is made of the following ingredients in parts by weight: sodium polyacrylate 4, acetyl Methyl propionate 6, maltol 3; the mass ratio of the modified salad oil, polyisobutylene and latent curing agent is 15:5:1.

[0022] In the above-mentioned embodiment:

[0023] Further, the modified salad oil is made of the following components in parts by weight: pepper oil 2, canola oil 1, grape seed oil 3, castor oil 12, butyrolactone 0.2, 2-propyl-thiophene 0.1, Methyl fiber 0.3, the preparation method of which is: mix pepper oil, canola oil, grape seed oil, and castor oil together according to their respective weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com