Geopolymeric material and preparation method thereof

A geopolymer cement and hydraulic technology, applied in the field of road engineering materials, can solve the problem of single raw material of geopolymer cement, achieve good economic benefits, improve early strength, and reduce impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a geopolymer cement material, which is made of the following raw materials in parts by weight: 100 parts of diaspore, 20 parts of phillips, 80 parts of slag, and 95 parts of soaking liquid. 4 parts of structural template agent, 4 parts of sodium hydroxide solution, and 5 parts of synergistic activator. in:

[0032] The soaking solution is a tert-butylamine prepolymer solution, the structural template agent is a sodium silicate solution, and the synergistic activator is a tert-butylamine prepolymer solution.

[0033] The tert-butylamine prepolymer is prepared from tert-butyl alcohol and urea through the following process: First, add urea, adjust the pH=7 with a sulfuric acid solution with a mass concentration of 30%, and add urea and tert-butylamine in a molar ratio of 1:1, Add tert-butanol according to the molar ratio between urea and tert-butanol as 2:1, heat to 45°C, and keep it warm for 15 minutes, then add concentrated sulfuric acid with a ...

Embodiment 2

[0046] This embodiment provides a geopolymer cement material, which is made of the following raw materials in parts by weight: 100 parts of diaspore, 80 parts of phillips, 20 parts of slag, and 140 parts of soaking liquid. 10 parts of structural template agent, 10 parts of sodium hydroxide solution, and 10 parts of synergistic activator.

[0047] The selection and specification of raw material in the present embodiment are identical with embodiment 1.

[0048] The preparation method of the geopolymer cement material in this embodiment is the same as that in Embodiment 1.

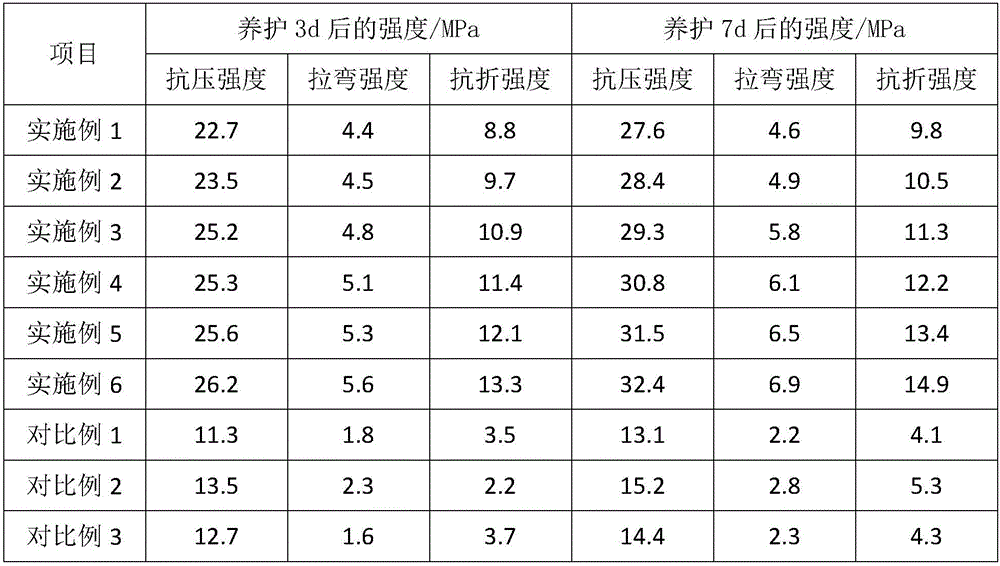

[0049] The performance test method of this embodiment is the same as that of Example 1, and the performance test results are shown in Table 1.

Embodiment 3

[0051]This embodiment provides a geopolymer cement material, which is made of the following raw materials in parts by weight: 100 parts of diaspore, 60 parts of phillips, 60 parts of slag, and 120 parts of soaking liquid. 7 parts of structural template agent, 7 parts of sodium hydroxide solution, and 10 parts of synergistic activator.

[0052] The selection and specification of raw material in the present embodiment are identical with embodiment 1.

[0053] The preparation method of the geopolymer cement material in this embodiment is the same as that in Embodiment 1.

[0054] The performance test method of this embodiment is the same as that of Example 1, and the performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com