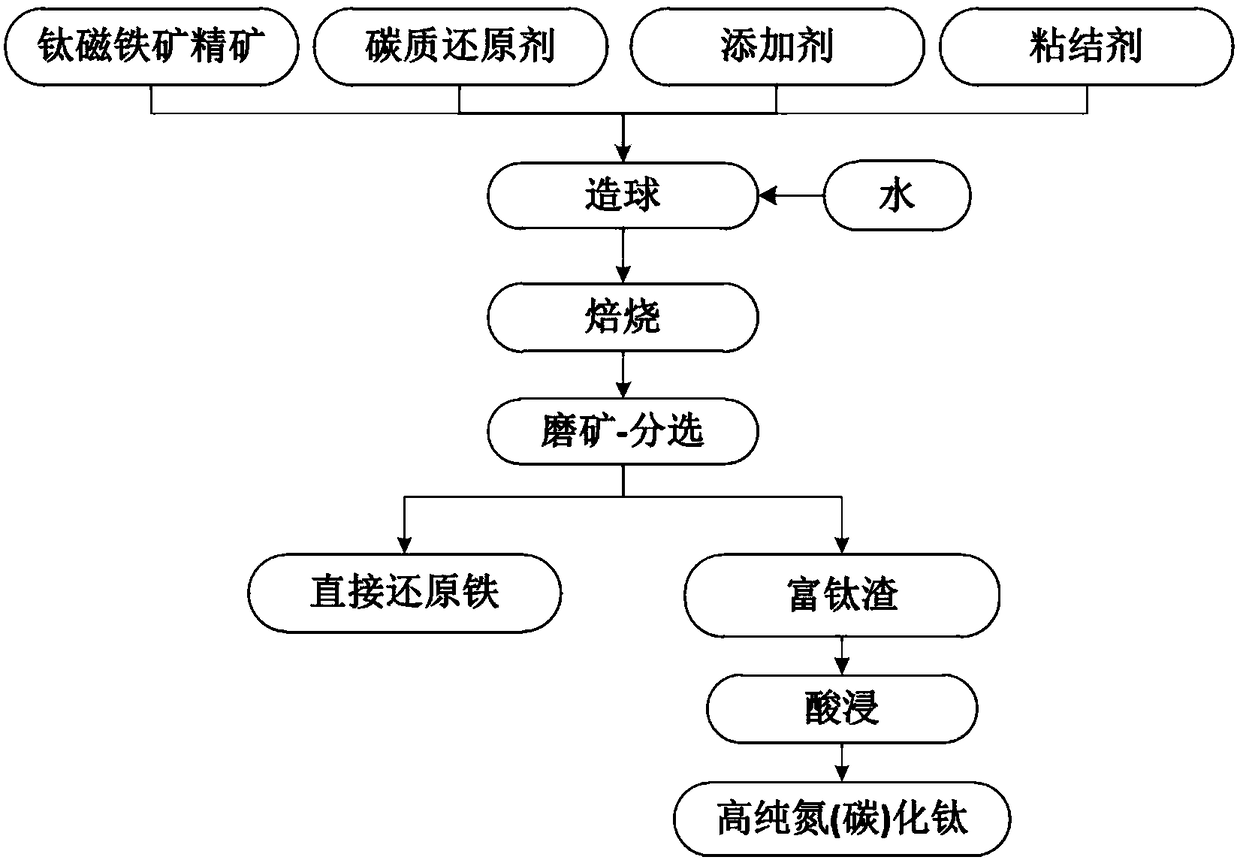

Method for producing direct reduced iron and titanium nitride carbide from titanium magnetite concentrate

A technology of titanium magnetite and titanium nitrogen carbide, which is applied in the direction of fluidized bed furnace, furnace, furnace type, etc., can solve the problems of large environmental pollution, harsh synthesis conditions, high production cost, etc., and achieve wide source of raw materials and high product value , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The grade of a titanium magnetite concentrate is TFe 57.31%, TiO 2 11.23%, of which the iron-bearing minerals are mainly titanomagnetite and a small amount of ilmenite, and basically do not contain other gangue minerals.

[0024] Weigh and mix titanomagnetite concentrate: anthracite: water glass according to the mass ratio of 100:22:3, then add water to the disc pelletizer to form carbon-containing pellets, and dry the carbon-containing pellets at 105°C , and then put it into a graphite crucible and cover it for protection. When the temperature of the muffle furnace was raised to 1300°C, the graphite crucible was put into the furnace for 90 minutes of calcination, and after the calcination was completed, the crucible was taken out and cooled naturally at room temperature. Grind the pellets after roasting, the grinding fineness is -0.074㎜, accounting for 80%. The recoveries were 96.42%, respectively. The magnetic separation tailings are titanium-rich slag, which is so...

Embodiment 2

[0026] The grade of a titanomagnetite concentrate is TFe 60.54%, TiO 2 6.98%, of which the iron-containing minerals are mainly titano-magnetite and a small amount of ilmenite, and basically do not contain other gangue minerals.

[0027] Titanium magnetite concentrate: carbonaceous reducing agent: additive: binder is weighed and mixed according to the mass ratio of 100:28:8:5, and then mixed with 12% water. The composition of the carbonaceous reducing agent is anthracite: bituminous coal: activated carbon: coke: semi-coke: petroleum coke: graphite The mass ratio is 40:10:10:10:10:10:10, anthracite, bituminous coal, activated carbon, coke, semi-coke , petroleum coke and graphite are all industrial products; the additive composition is calcium hydroxide: potassium carbonate: sodium sulfate: sodium carbonate: sodium sulfate: calcium fluoride: sodium borate mass ratio is 10:15:10:10:15:15: 10. Calcium hydroxide, potassium carbonate, potassium sulfate, sodium carbonate, sodium sulf...

Embodiment 3

[0029] The grade of a titanium magnetite concentrate is TFe 47.87%, TiO 2 19.01%, of which the iron-containing minerals are mainly titano-magnetite and a small amount of ilmenite, and basically do not contain other gangue minerals.

[0030]Titanium magnetite concentrate: carbonaceous reducing agent: additive: binder is weighed and mixed according to the mass ratio of 100:18:9:5. The composition of the carbonaceous reducing agent is anthracite: bituminous coal: activated carbon: coke: semi-coke: petroleum coke: graphite The mass ratio is 50:5:15:5:15:5:5, anthracite, bituminous coal, activated carbon, coke, semi-coke , petroleum coke and graphite are all industrial products; the additive composition is calcium hydroxide: potassium carbonate: sodium sulfate: sodium carbonate: sodium sulfate: calcium fluoride: sodium borate mass ratio is 8:20:15:5:20:10: 22. Calcium hydroxide, potassium carbonate, potassium sulfate, sodium carbonate, sodium sulfate, calcium fluoride, and sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com