Flotation reagent for high-mud micro-fine-particle pyrite type gold ore and use method of flotation reagent

A pyrite-type, flotation agent technology, applied in flotation, solid separation, etc., can solve the problems affecting flotation indicators, low Au grade of gold concentrate, low Au recovery rate, etc., to improve the grade and recovery rate , Reduce the pressure of mine environmental protection, excellent flotation index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

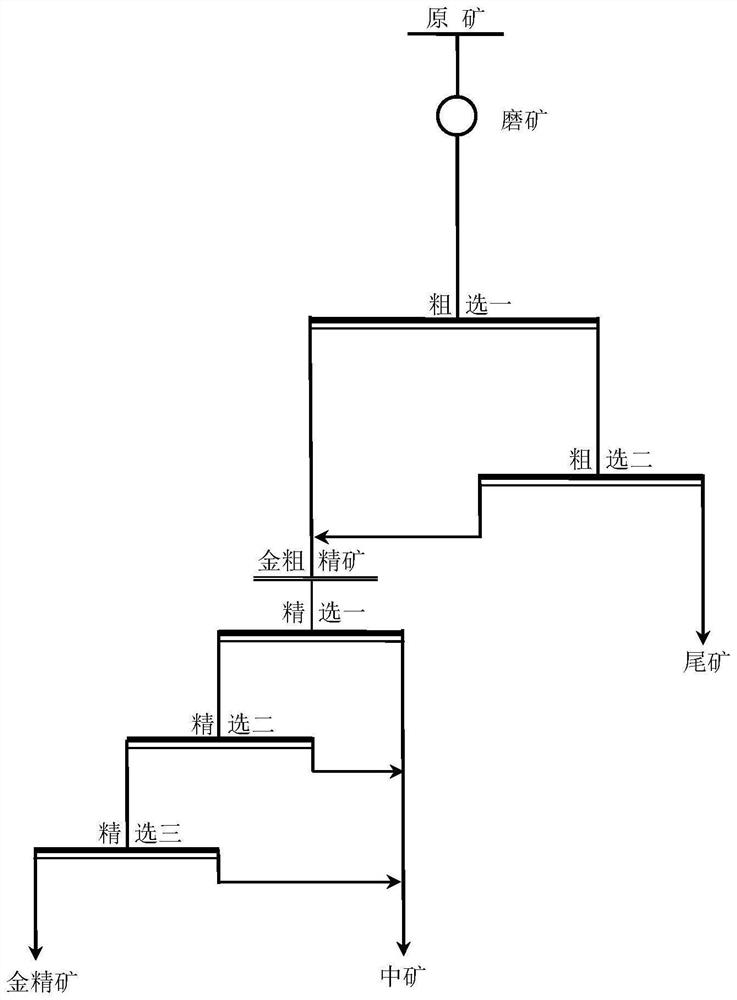

Method used

Image

Examples

Embodiment 1

[0031] A gold deposit in Northwest China is a high-temperature hydrothermally altered rock-type gold ore hosted in the compressional structural fracture zone of mylonite. The main valuable element is gold, with associated low-grade silver, belonging to the fine-grained-super The fine-grained disseminated type is extremely difficult to select metallurgical ores. The main precious metal minerals in the ore are gold minerals, mainly fine-grained gold, and the grade of Au is 2.4g / t. Most of the gold particles are contained in arsenopyrite in a microscopic and ultra-microscopic dispersion state, followed by gangue minerals such as sericite, chlorite and quartz, and a few are coexisted or encapsulated with pyrite and pyrrhotite. The metal sulfide minerals in the ore are mainly pyrite, arsenopyrite, orthorhomite and pyrrhotite, accounting for about 5% of the total mineral content. The main gangue minerals are quartz, sericite, chlorite, feldspar, kaolin, etc. The hardness of gangue ...

Embodiment 2

[0043] Example 2 adopts the same raw ore, dosage of chemicals and technological process as in Example 1, the difference is that the combination mode of the gold ore combination collector adopted in Example 2 is different from that in Example 1, and the gold ore of Example 2 The combined collector is: Y-89 xanthate + No. 25 black medicine + collector EMB-506.

Embodiment 3

[0045] Example 2 adopts the same raw ore, dosage of chemicals and technological process as in Example 1, the difference is that the combination mode of the gold ore combination collector adopted in Example 2 is different from that in Example 1, and the gold ore of Example 2 The combined collector is: amyl xanthate + No. 25 black medicine + collector EMB-506.

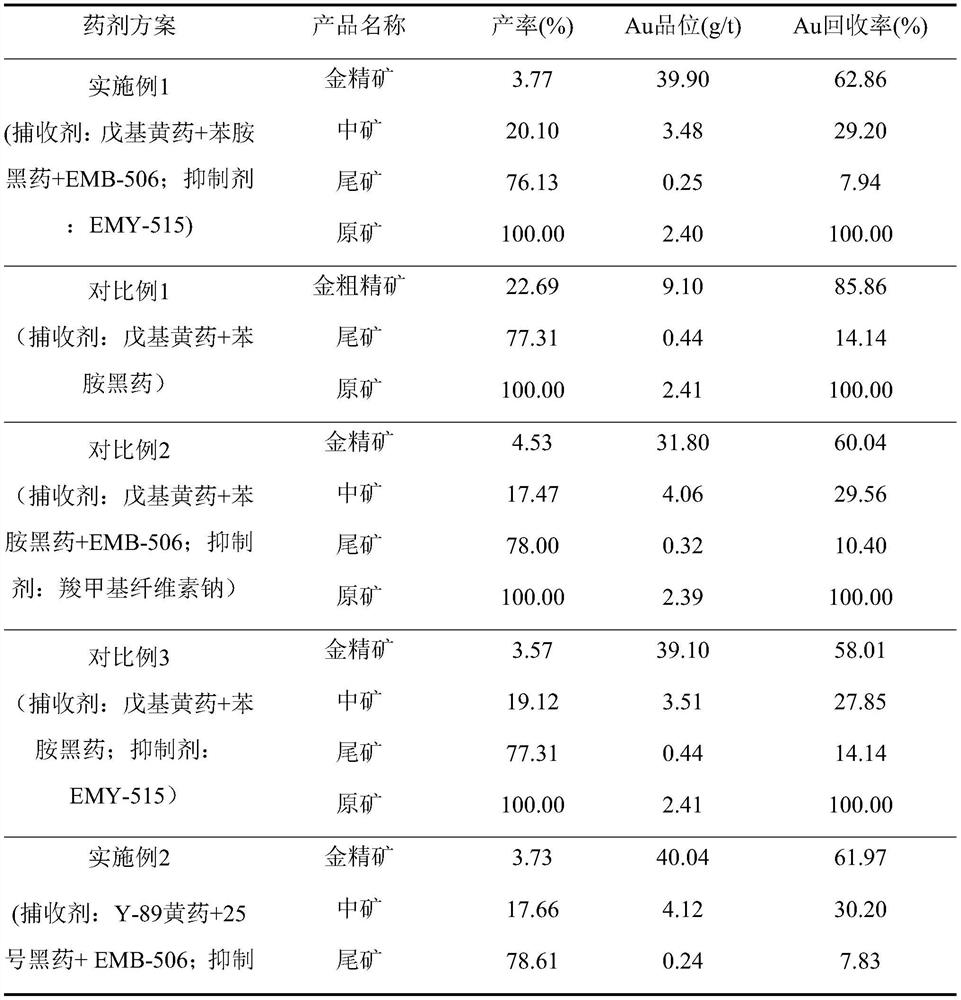

[0046] The flotation results of the high-mud fine-grained pyrite-type gold ore in the above Examples 1-3 and Comparative Examples 1-3 are shown in Table 1.

[0047] Table 1

[0048]

[0049]

[0050] As can be seen from Table 1, after adopting the flotation agent of the present invention, under the same conditions, adding the collector EMB-506 as the auxiliary collector, the recovery rate of Au in the gold coarse concentrate product obtained by the two roughings is higher than When adding, it increased by 6.2 percentage points; in the selection process, using inhibitor EMY-515 as inhibitor has higher Au grade than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com