A method for extracting metals from fly ash by molten salt electrolysis

A technology for metal extraction and molten salt electrolysis, applied in the field of metallurgy, can solve the problems of non-recyclable alkali reactant, equipment corrosion, low purification rate, etc., and achieve the effects of green and efficient comprehensive utilization, short process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Na 3 AlF 6 and AlF 3 Mix evenly to make cryolite-based molten salt, the mixing ratio is NaF and AlF in cryolite-based molten salt 3 The molar ratio is 2;

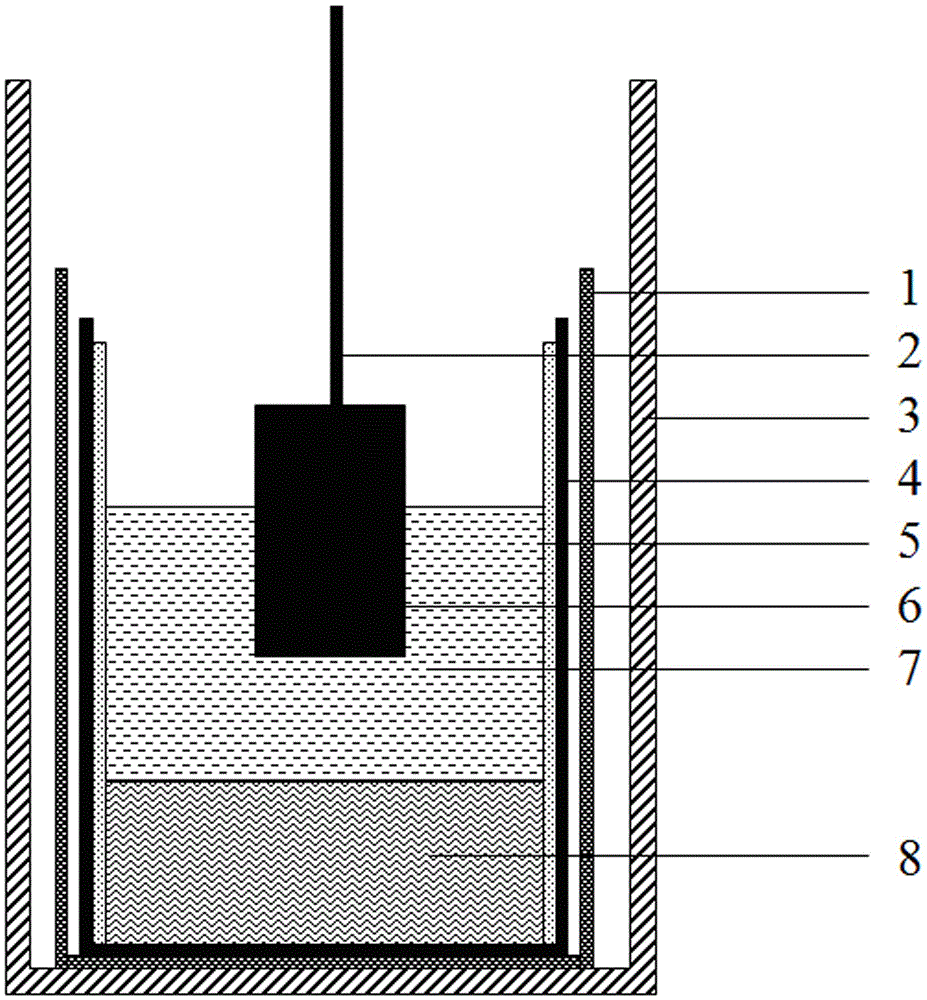

[0035] Put the metal aluminum in the electrolytic cell; then place the cryolite-based molten salt in the electrolytic cell, and then add fly ash, the amount of fly ash added is 5% of the total weight of the cryolite-based molten salt and fly ash; The composition of fly ash contains Al by weight percentage 2 o 3 52.75%, SiO 238.05%, CaO3.88%, TiO 2 1.97%, Fe 2 o 3 1.86%, MgO0.51%, K 2 0.10%, the balance is impurities;

[0036] Heating cryolite-based molten salt and fly ash to 910°C, metal aluminum is melted into liquid aluminum, the liquid aluminum is used as the cathode, and the carbon anode is used as the anode; electrolysis is carried out by electrification, and the current density between the cathode and the anode is controlled to be 0.4A / cm 2 , the electrolysis time is 8h. After starting the electrol...

Embodiment 2

[0039] The method that molten salt electrolysis extracts metal from fly ash is the same as embodiment 1, and difference is:

[0040] (1) NaF and AlF in cryolite-based molten salt 3 The molar ratio is 2.2;

[0041] (2) The amount of fly ash added to the electrolytic cell is 3% of the total weight of cryolite-based molten salt and fly ash; the composition of fly ash contains Al 2 o 3 39.04%, SiO 2 55.24%, CaO0.25%, TiO 2 0.77%, Fe 2 o 3 3.76%, MgO0.10%, K 2 0.01%, the remainder is impurities;

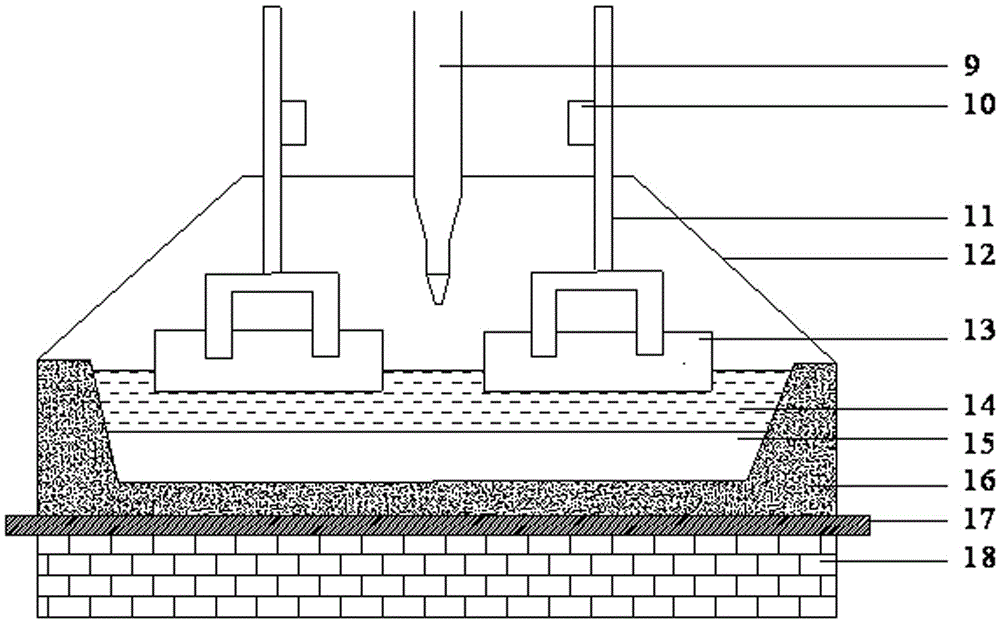

[0042] (3) Heat cryolite-based molten salt and fly ash to 955°C, use an inert anode as the anode, and the inert anode is a metal-based aluminum electrolytic inert anode; electrify for electrolysis, and the current density between the cathode and the anode is 0.6A / cm 2 , the electrolysis time is 7h; the amount of fly ash added each time is 30% of the total weight of fly ash in the electrolytic cell when electrolysis is started;

[0043] (4) The composition of the aluminum-based a...

Embodiment 3

[0045] The method that molten salt electrolysis extracts metal from fly ash is the same as embodiment 1, and difference is:

[0046] (1) NaF and AlF in cryolite-based molten salt 3 The molar ratio is 2.4;

[0047] (2) The amount of fly ash added to the electrolytic cell is 10% of the total weight of cryolite-based molten salt and fly ash; the composition of fly ash contains Al by weight percentage 2 o 3 47.11%, SiO 2 34.30%, CaO3.90%, TiO 2 1.86%, Fe 2 o 3 6.20%, MgO3.70%, K 2 O2.10%, the balance is impurities;

[0048] (3) Heat cryolite-based molten salt and fly ash to 965°C; electrify for electrolysis, and the current density between the cathode and anode is 0.7A / cm 2 , the electrolysis time is 6h; the amount of fly ash added each time is 40% of the total weight of fly ash in the electrolytic cell when the electrolysis is started;

[0049] (4) The composition of the aluminum-based alloy contains Al67.9%, Si17.9%, Fe5.4%, Ti8.4% by weight percentage, and the rest is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com