Card protective film, manufacturing method, and payment card

A manufacturing method and protective film technology, applied in the field of payment cards, can solve the problems of easy deformation of cards, low temperature resistance level, long-term failure, etc., and achieve the effects of improving peeling and breaking, improving temperature resistance level, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

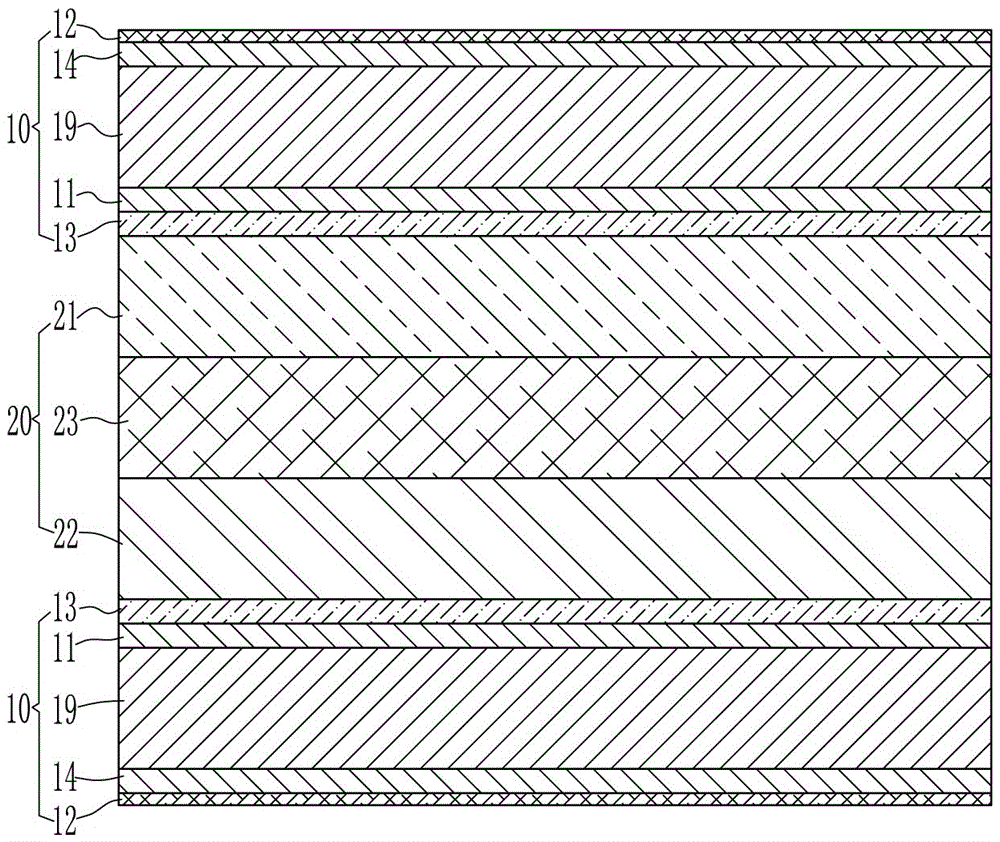

[0069] Embodiment one: see figure 2 , making a five-layer card protective film 10 with a thickness of 50 microns.

[0070] Step A, the connection layer and the core layer are formed by one-time molding, and polyethylene terephthalate is prepared as the raw material of the core layer 19, and thermoplastic polyester resin is used as the material of the first connection layer 11 and the second connection layer 14, Among them, the thermoplastic polyester resin is composed of polydiallyl phthalate (60% to 80% by weight) and acetic acid (20% to 40% by weight), for example, 70% by weight polyphthalate di The combination of allyl ester and 30% by weight of acetic acid constitutes a thermoplastic polyester resin, and the two sides of the core layer 19 made of a biaxially stretched multilayer co-extrusion system have a first connection layer 11 and a second connection layer 14 respectively; the core layer 19 and the molding total thickness of the two connecting layers 11, 14 are contr...

Embodiment 2

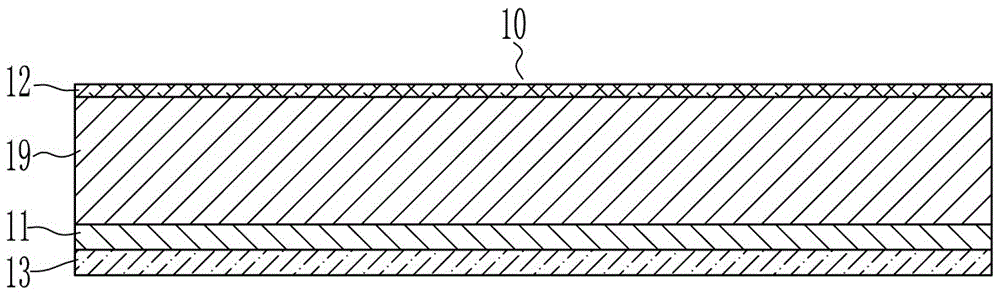

[0074] Embodiment two: see figure 1 , making a four-layer card protective film 10 with a thickness of 35 microns.

[0075] Step A, the connection layer and the core layer are formed by one-time molding, and polyethylene terephthalate is prepared as the raw material of the core layer 19, and thermoplastic polyester resin is used as the material of the first connection layer 11, wherein the thermoplastic polyester resin is according to Combination of polydiallyl phthalate (60% to 80% by weight) and acetic acid (20% to 40% by weight), for example, polydiallyl phthalate with a weight percentage of 65% and weight percent A combination of 35% acetic acid constitutes a thermoplastic polyester resin, and a first connection layer 11 is formed on one side of the core layer 19 made of a biaxially stretched multilayer co-extrusion system; the molding total thickness of the core layer 19 and the first connection layer 11 is controlled at 30 microns. The thickness of the first connection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com