Hydrothermal synthesis method of a nitrogen-doped graphene-supported cobalt oxygen reduction reaction electrocatalyst

A technology of nitrogen-doped graphene and electrocatalyst, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of conductivity and catalytic stability defects, and achieve simple and easy-to-control preparation methods, high selectivity, and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

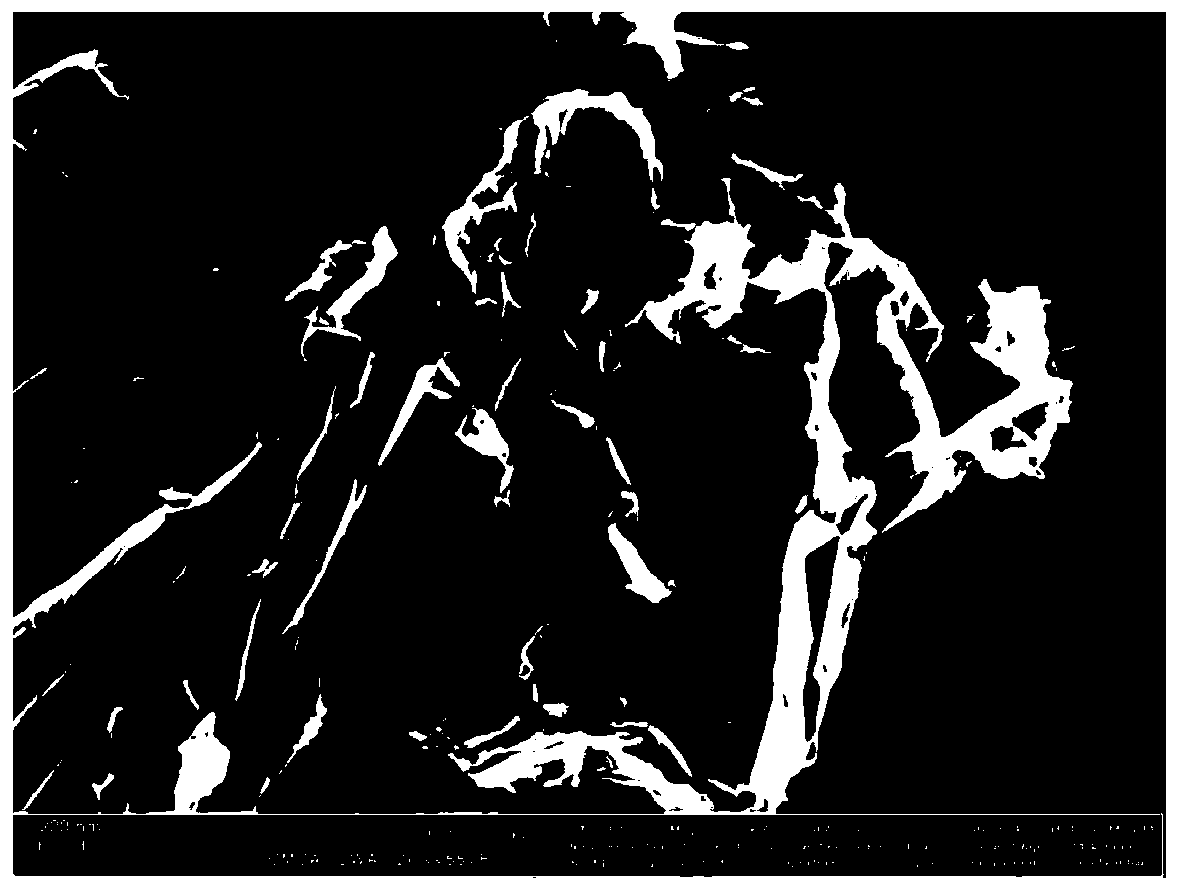

Image

Examples

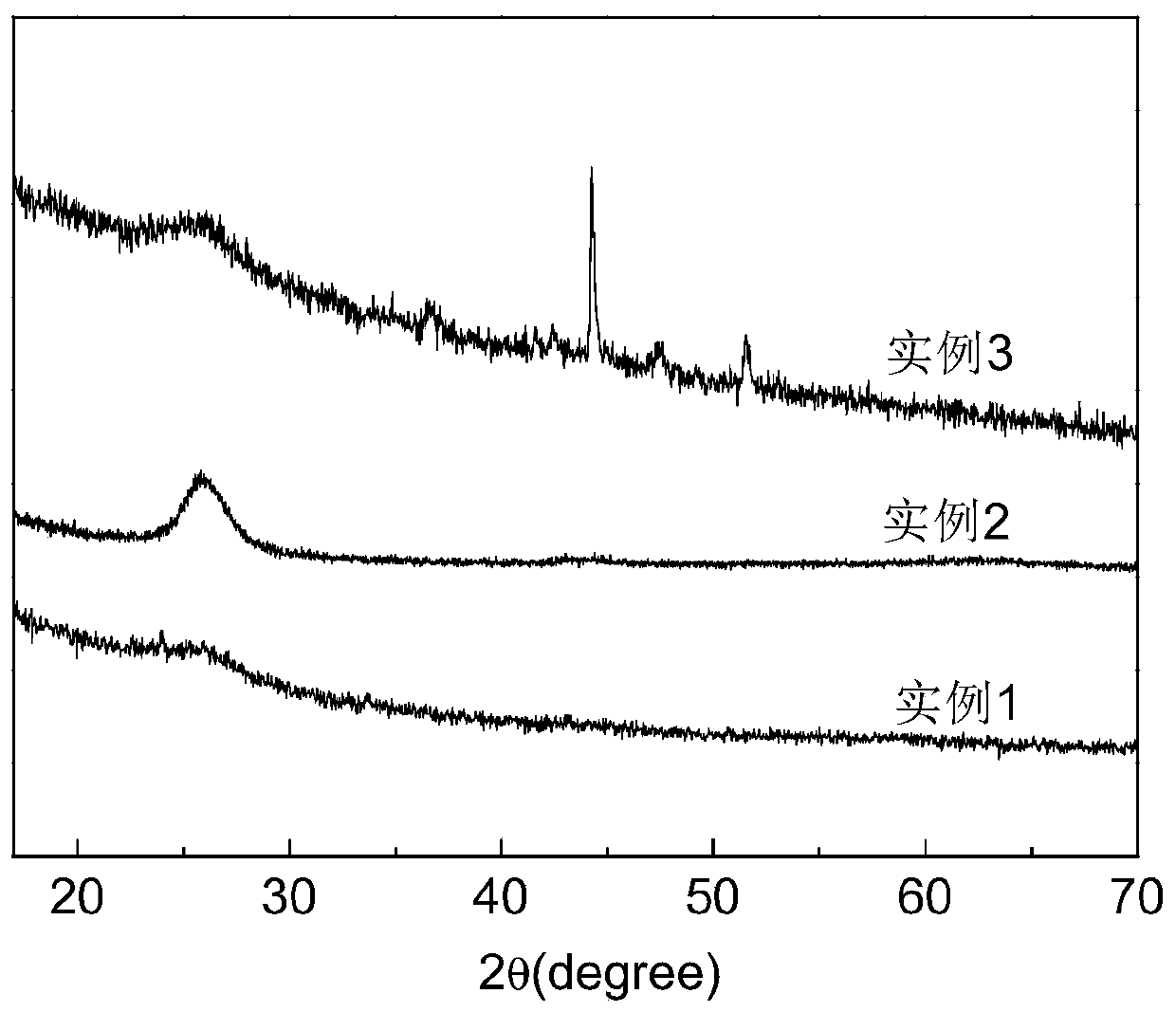

Embodiment 1

[0034] 1. Using graphite powder with a particle size of less than 20 μm as raw material, graphene oxide (GO) was prepared by the conventional Hummer method;

[0035] 2. Mix and grind GO and urea according to the mass ratio of 1:10, put them into a 160°C oven for nitrogen-doped heat treatment for 6 hours, and after cooling, crush the nitrogen-doped GO and wash it with deionized water, and then add it into deionized water for ultrasonic dispersion The concentration in 0.5h is 1.5g·L -1 uniform dispersion liquid; add 0.5 times GO quality cobalt nitrate crystals to the dispersion liquid, stir and disperse evenly, then transfer the mixed liquid into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 12 hours; after cooling, open the reaction kettle and add Hydrazine hydrate with 15 times the quality of GO, adjust the pH value of the solution to 10 with ammonia water, seal the reaction vessel, and perform hydrothermal reduction reaction at 180°C for 10 ...

Embodiment 2

[0039] 1. Using graphite powder with a particle size of less than 20 μm as raw material, graphene oxide (GO) was prepared by the conventional Hummer method;

[0040] 2. Mix and grind GO and urea according to the mass ratio of 1:3, put them into an oven at 180°C for nitrogen-doped heat treatment for 4 hours, and after cooling, crush the nitrogen-doped GO and wash it with deionized water, then add it into deionized water for ultrasonic dispersion The concentration in 0.5h is 1.5g·L -1 The uniform dispersion liquid; transfer the dispersion liquid into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 140°C for 4 hours; open the reaction kettle after cooling, adjust the pH value of the solution to 10 with ammonia water, add hydrazine hydrate 10 times the quality of GO and seal it Reaction kettle, hydrothermal reduction reaction at 110°C for 4h, the reaction solution was cooled and filtered under reduced pressure, washed twice with deionized water and absolute ...

Embodiment 3

[0045] 1. Using graphite powder with a particle size of less than 20 μm as raw material, graphene oxide (GO) was prepared by the conventional Hummer method;

[0046] 2. Mix and grind GO and urea according to the mass ratio of 1:5, put them into an oven at 120°C for nitrogen-doped heat treatment for 24 hours, and after cooling, crush the nitrogen-doped GO and wash it with deionized water, then add it into deionized water for ultrasonic dispersion The concentration in 0.5h is 1.5g·L -1 A homogeneous dispersion liquid; add cobalt acetate crystals twice the quality of GO to the dispersion liquid, stir and disperse evenly, transfer the mixed liquid into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 4 hours; open the reaction kettle after cooling, and add Hydrazine hydrate with 40 times the quality of GO, adjust the pH value of the solution to 10 with ammonia water, seal the reaction vessel, and perform hydrothermal reduction reaction at 140°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com