Method for preparing hierarchical pore carbonic oxide microsphere material

A technology of multi-level pores and carbon-nitrogen, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of cumbersome steps, unfavorable industrial production, and high production costs of nitrogen-doped porous carbon materials, and achieve excellent structures Stability, excellent electrochemical performance, short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

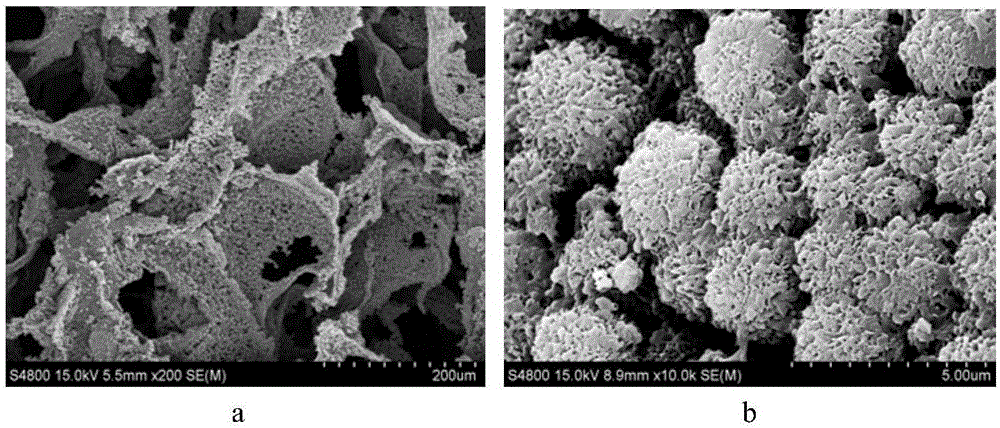

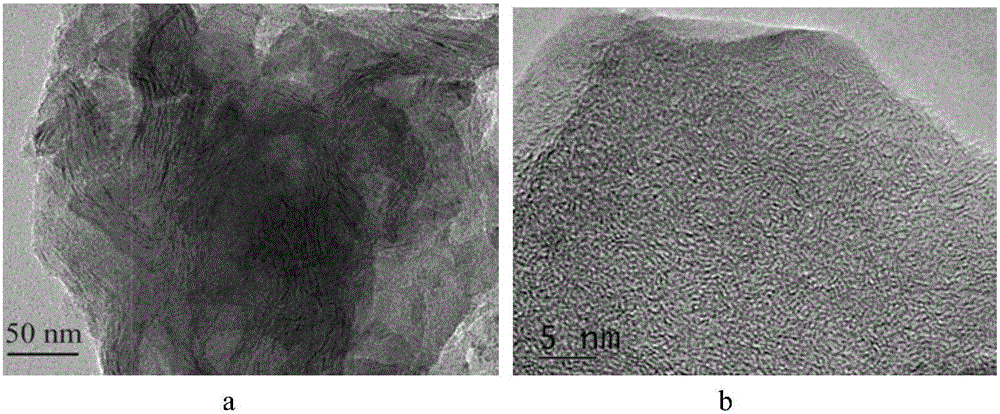

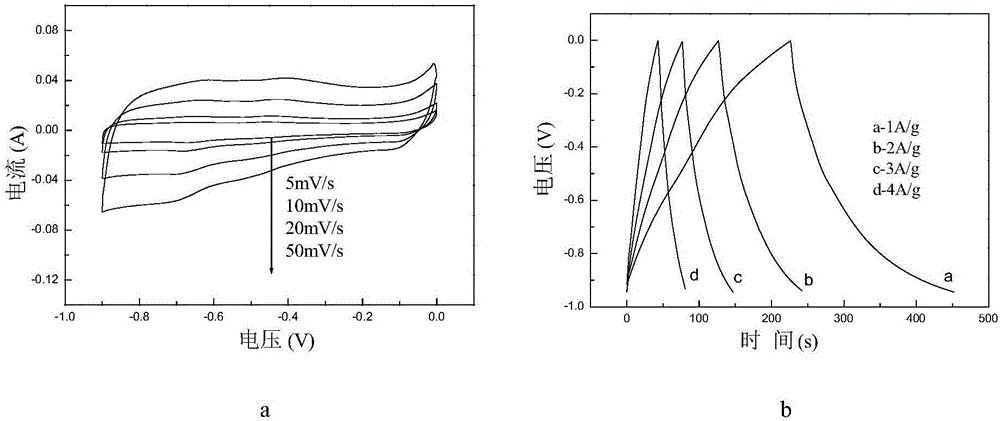

[0035] 1. To prepare the hierarchically porous carbon-nitrogen microsphere material, follow the steps below:

[0036] (1) Preparation of PAA solution

[0037]Polyamic acid (PAA) is obtained by polycondensation of pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) in the polar solvent N-methylpyrrolidone (NMP). Firstly, ODA and PMDA were recrystallized with ethanol and acetic anhydride respectively, and sealed for storage; the water in NMP was removed by vacuum distillation, and the redistilled NMP was stored in a desiccator; , ODA and PMDA with a molar ratio of 1:1 were added to the solvent NMP, stirred for 6hr, and polycondensed to prepare a polyamic acid solution with a mass percentage of 5wt%.

[0038] (2) Preparation of Hierarchical Porous Carbon Nitrogen Microspheres

[0039] A, adopt 15ml concentration to be the PAA solution impregnation volume of 5wt% be 15cm 3 The commercial polyurethane (PU) foam was dried under vacuum at 50°C for 20h.

[0040] B...

Embodiment 2

[0049] 1. To prepare the hierarchically porous carbon-nitrogen microsphere material, follow the steps below:

[0050] (1) Preparation of PAA solution

[0051] PAA is obtained by polycondensation of pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) in the polar solvent N,N-dimethylacetamide (DMAC). Firstly, ODA and PMDA were recrystallized with ethanol and acetic anhydride respectively, and sealed for storage; the water in DMAC was removed by vacuum distillation, and the redistilled DMAC was stored in a desiccator; , ODA and PMDA with a molar ratio of 1:1 were added to the solvent DMAC, stirred for 8 hours, and polycondensed to prepare a PAA solution with a mass percentage of 10 wt%.

[0052] (2) Preparation of Hierarchical Porous Carbon Nitrogen Microspheres

[0053] A, adopt 10ml concentration to be the PAA solution impregnation volume of 10wt% be 12cm 3 The commercial PU foam was dried under vacuum at 70°C for 15h.

[0054] B. Heat the impregnated PU f...

Embodiment 3

[0061] 1. To prepare the hierarchically porous carbon-nitrogen microsphere material, follow the steps below:

[0062] (1) Preparation of PAA solution

[0063] PAA is obtained by polycondensation of pyromellitic dianhydride (PMDA) and 4,4'-diaminodiphenyl ether (ODA) in the polar solvent N,N-dimethylformamide (DMF). First, recrystallize ODA and PMDA with ethanol and acetic anhydride respectively, and seal them for storage; use vacuum distillation to remove the water in DMF, and put the re-distilled DMF in a desiccator; , ODA and PMDA with a molar ratio of 1:1 were added to the solvent DMF, stirred for 10 hr, and polycondensed to prepare a PAA solution with a mass percent content of 15 wt%.

[0064] (2) Preparation of Hierarchical Porous Carbon Nitrogen Microspheres

[0065] A, adopt 5ml concentration to be the PAA solution impregnation volume of 15wt% be 10cm 3 The commercial PU foam was dried under vacuum at 90°C for 6h.

[0066] B. Heat the impregnated PU foam under a nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com