Preparation method of modified superfine calcium carbonate powder and product of preparation method

A technology of ultrafine calcium carbonate and powder, which is applied in chemical instruments and methods, dyeing physical treatment, dyeing organic silicon compound treatment, etc., can solve the problem of inability to effectively improve the dry and wet covering effect of architectural coatings, the addition of titanium dioxide, the ultrafine weight The high surface activity of high-quality calcium carbonate powder affects the performance and product application effect, and achieves excellent anti-sedimentation effect, improved storage stability, and excellent modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

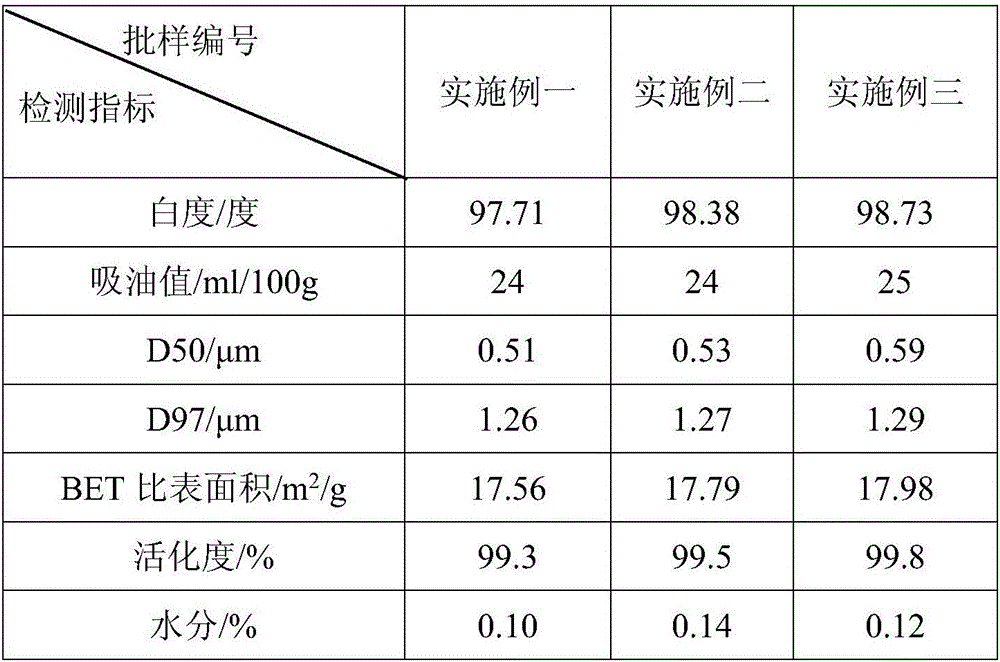

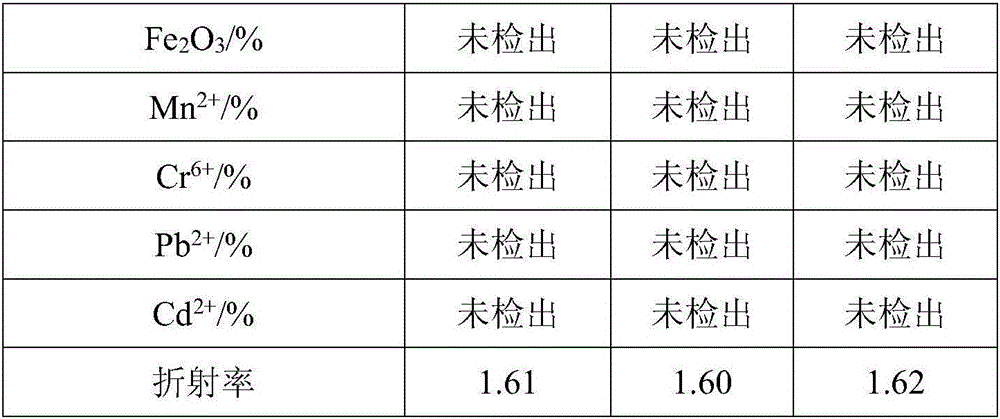

Embodiment 1

[0037] Calcite ore and kaolin are crushed at a ratio of 100:1, and ground into 400 mesh dry powder, which is configured into a slurry with a solid content of 80%, and three kinds of polyacrylic acid ammonium salt, sodium hexametaphosphate and polyacrylic acid sodium salt are added to disperse agent, the dispersant accounts for 6% of the dry powder mass fraction, and the ratio of the three dispersants is 6:1:7. The dispersed slurry is poured into a 3600L vertical wet grinder for wet grinding, and ground into a slurry with a fineness of 10,000 mesh. After flash drying, it is collected by a cloth bag and added to a mixer for depolymerization and dispersing. It maintains the original particle size of the particles, and then puts them into the surface modifier through a spiral reamer, and adds a solid modifier, a liquid modifier and a hyperdispersant with a certain powder mass ratio respectively, and performs wrapping treatment to further improve Its dispersing effect avoids second...

Embodiment 2

[0040] Calcite ore and kaolin are crushed at a ratio of 80:1, and ground into 400 mesh dry powder, which is configured into a slurry with a solid content of 80%, and three kinds of polyacrylic acid ammonium salt, sodium hexametaphosphate and polyacrylic acid sodium salt are added to disperse The dispersant accounts for 6% of the dry powder mass fraction, and the ratio of the three dispersants is 9:1:4. The dispersed slurry is poured into a 3600L vertical wet grinder for wet grinding, and ground into a slurry with a fineness of 8000 meshes. After being flashed and dried, it is collected by a cloth bag and added to a dispersing machine for depolymerization and dispersing. It maintains the original particle size of the particles, and then puts them into the surface modifier through a spiral reamer, and adds a solid modifier, a liquid modifier and a hyperdispersant with a certain powder mass ratio respectively, and performs wrapping treatment to further improve Its dispersing effect...

Embodiment 3

[0043] Calcite ore and kaolin are crushed at a ratio of 50:1, and ground into 400 mesh dry powder, which is configured into a slurry with a solid content of 80%, and three kinds of polyacrylic acid ammonium salt, sodium hexametaphosphate and polyacrylic acid sodium salt are added to disperse agent, the dispersant accounts for 6% of the dry powder mass fraction, and the ratio of the three dispersants is 4:1:5. The dispersed slurry is poured into a 3600L vertical wet grinder for wet grinding, and ground into a slurry with a fineness of 9000 mesh. After flash drying, it is collected by a cloth bag and added to a disperser for depolymerization and dispersal. It maintains the original particle size of the particles, and then puts them into the surface modifier through a spiral reamer, and adds a solid modifier, a liquid modifier and a hyperdispersant with a certain powder mass ratio respectively, and performs wrapping treatment to further improve Its dispersing effect avoids second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com