Tantalum-doped hydroxyapatite coating bone implantation material and preparation method thereof

A technology of tantalum hydroxyapatite and bone implant materials, which is applied in coating, metal material coating process, pharmaceutical formulation, etc. The effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0042] The preparation methods of the four embodiments are identical, as follows:

[0043] Using pure titanium sheet as matrix, and pretreatment:

[0044] First, use metallographic sandpaper to grind and polish the metal sheet to 400 mesh step by step, then ultrasonically clean it with acetone, anhydrous ethanol and deionized water for 10 minutes, and the frequency is 40KHz; It was ultrasonically cleaned with acetone, anhydrous ethanol and deionized water for 10 min in sequence, and the frequency was 30 KHz.

[0045]Mix medical tantalum powder (particle size 35-75 μm) and hydroxyapatite (particle size 15-50 μm) according to the preset mass ratio, put it in a ball mill for full ball milling for 4 hours (rotation speed is 200 rpm), dry and sieve . Atmospheric plasma spraying equipment is used, with argon as the main gas (air supply volume 47L / min) and helium as the auxiliary (air supply volume 12L / min). Under the conditions of power 30KW, powder feeding rate 13g / min, and spra...

Embodiment 5-7

[0051] The only difference from Example 1 is the thickness of the coating, which is 90 μm, 100 μm, and 130 μm, respectively.

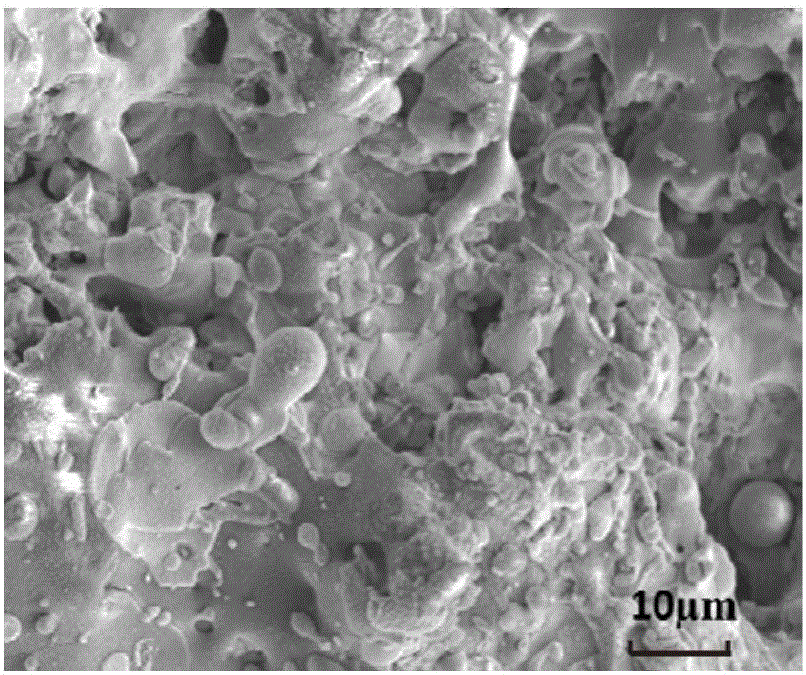

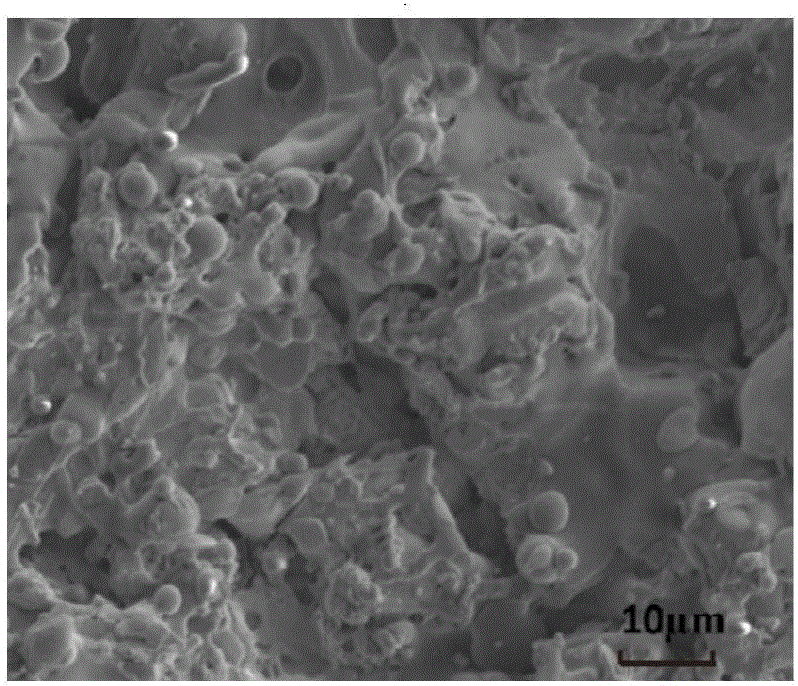

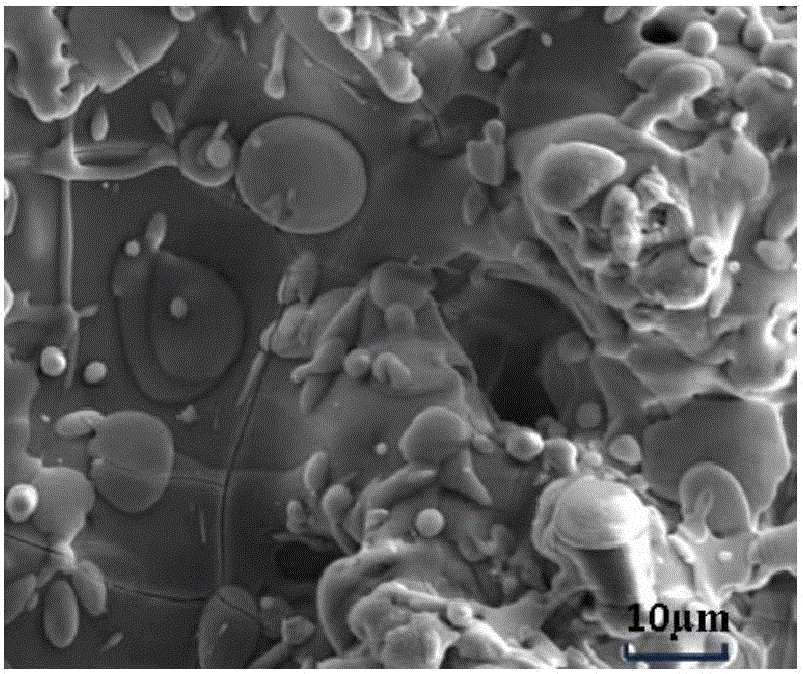

[0052] The SEM photos show that the material coatings of Examples 5 to 7 all have a multi-level pore structure.

[0053] The pore size range, porosity, coating bonding strength and coating surface roughness of Examples 5 to 7 were tested, and the results are shown in Table 2.

[0054] Table 2

[0055]

[0056]

Embodiment 8

[0058] Using pure titanium sheet as matrix, and pretreatment:

[0059] First, use metallographic sandpaper to grind and polish the metal sheet to 400 mesh step by step, then ultrasonically clean it with acetone, anhydrous ethanol and deionized water for 10 minutes, and the frequency is 40KHz; It was ultrasonically cleaned with acetone, anhydrous ethanol and deionized water for 10 min in sequence, and the frequency was 30 KHz.

[0060] Mix medical tantalum powder (particle size: 35-75μm) and hydroxyapatite (particle size: 15-50μm) in a mass ratio of 9:1, put it in a ball mill for full ball milling for 4 hours (rotation speed is 200 rpm), dry and sieve . Atmospheric plasma spraying equipment is used, with argon as the main gas (gas supply volume 55L / min) and helium as the auxiliary (gas supply volume 8L / min). Under the conditions of power 30KW, powder feeding rate 13g / min, and spraying distance of 100mm, the mixed powder is uniformly sprayed on the pure titanium sheet after sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com