Organic-inorganic nanocomposite reinforced polyethylene material and preparation method thereof

An inorganic nano-composite reinforcement technology, applied in the field of polyethylene materials and preparation, can solve the problems of inability to achieve long-term anti-violet, polyethylene matrix performance damage, and inability to eliminate polyethylene matrix damage, so as to achieve easy industrial preparation and low production cost. Low, reasonable composition of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

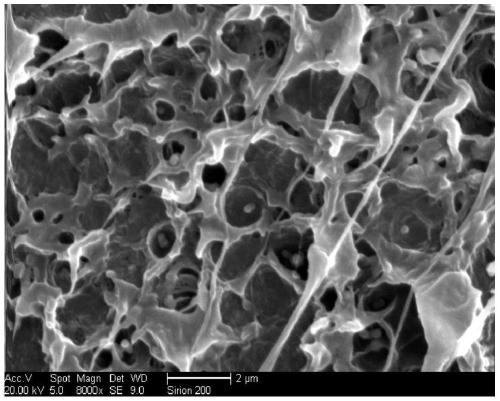

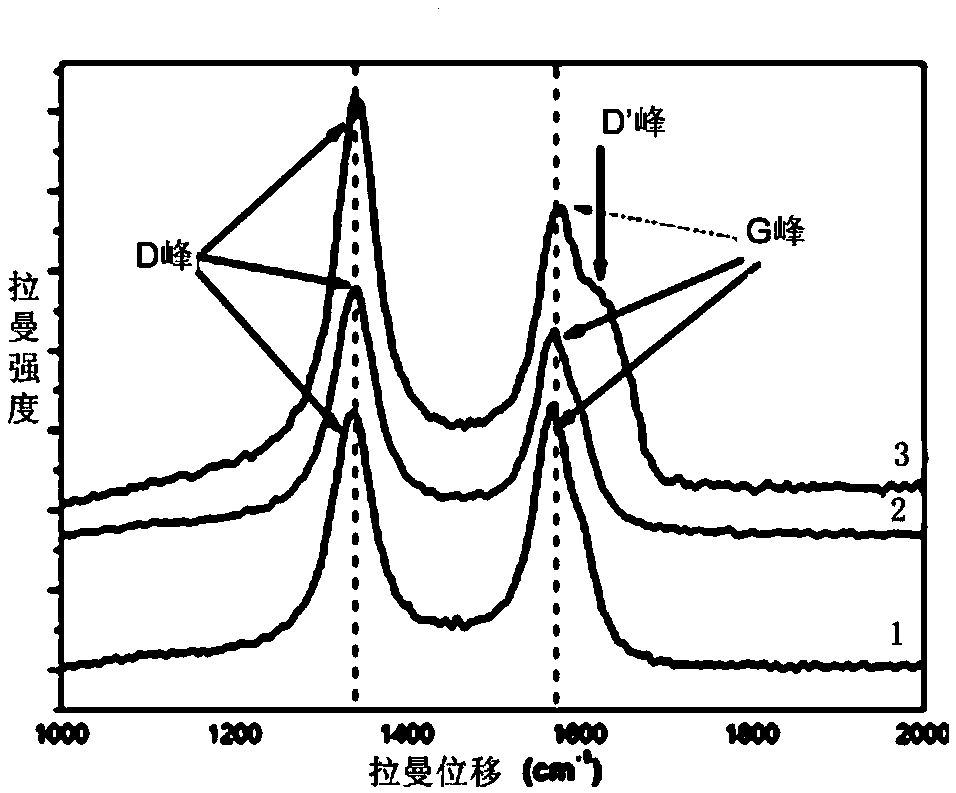

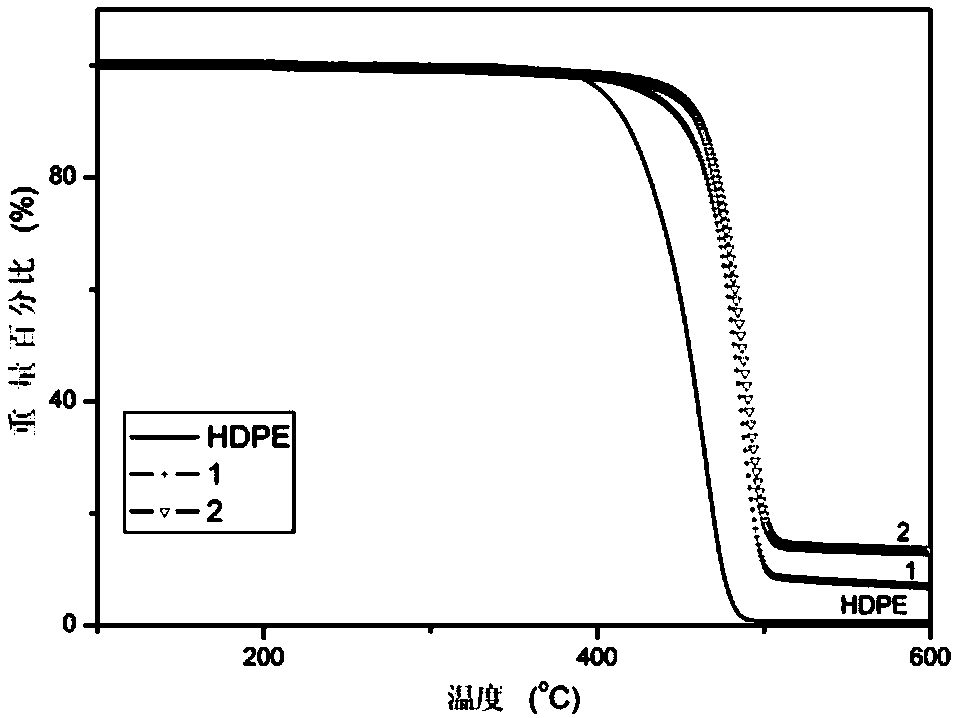

[0045] Step 1, first mix sulfuric acid ≥ 96wt% and nitric acid ≥ 63wt% according to the weight ratio of 1:1 to obtain mixed acid. According to the weight ratio of 1:10, the carbon nanotubes were placed in a mixed acid at 50°C and stirred for 12 hours, and the reaction solution was sequentially subjected to solid-liquid separation, washing and drying; wherein the carbon nanotubes were multi-wall For carbon nanotubes, the solid-liquid separation treatment is filtration, the washing treatment is to use deionized water to wash and filter the solid matter until the washing liquid is neutral, and the drying treatment is to dry the washed solid matter at 50°C for 48 hours to obtain purified carbon nanotube.

[0046] Step 2, first add the purified carbon nanotubes to a 10wt% surface modifier solution, stir and react at 70°C for 37h and then dry; wherein, the weight of the purified carbon nanotubes and the surface modifier in the surface...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] Step 1, first mix sulfuric acid ≥ 96wt% and nitric acid ≥ 63wt% according to the weight ratio of 1:1.5 to obtain mixed acid. According to the weight ratio of 2:10, the carbon nanotubes were placed in a mixed acid at 55°C and stirred for 11 hours, and the reaction solution was sequentially subjected to solid-liquid separation, washing and drying; wherein the carbon nanotubes were multi-wall For carbon nanotubes, the solid-liquid separation treatment is filtration, the washing treatment is to wash and filter the solid matter with deionized water until the washing liquid is neutral, and the drying treatment is to dry the washed solid matter at 55°C for 48 hours to obtain purified carbon nanotube.

[0050] Step 2, first add the purified carbon nanotubes to a 20wt% surface modifier solution, stir and react at 75°C for 36 hours and then dry; wherein, the weight of the purified carbon nanotubes and the surface modifier in the su...

Embodiment 3

[0052] The concrete steps of preparation are:

[0053] Step 1, first mix sulfuric acid ≥ 96wt% and nitric acid ≥ 63wt% according to the weight ratio of 1:2 to obtain the mixed acid. According to the weight ratio of 3:10, the carbon nanotubes were placed in a mixed acid at 60°C for 10 hours of stirring reaction, and the reaction solution was sequentially subjected to solid-liquid separation, washing and drying; wherein the carbon nanotubes were multi-walled For carbon nanotubes, the solid-liquid separation process is filtration, the washing process is to use deionized water to wash and filter the solid matter until the washing liquid is neutral, and the drying process is to dry the washed solid matter at 60°C for 48 hours to obtain purified carbon nanotube.

[0054] Step 2, first add the purified carbon nanotubes to a 30wt% surface modifier solution, and then dry them after stirring and reacting for 35 hours at 80°C; wherein, the weight of the purified carbon nanotubes and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com