A kind of regeneration method of nitrous oxide decomposition catalyst

A technology for catalysts and supported catalysts, applied in catalyst regeneration/reactivation, molecular sieve catalysts, separation methods, etc., can solve problems such as limiting the development of nitrous oxide tail gas emission reduction technology, save time and labor costs, and have high reactivation efficiency , The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

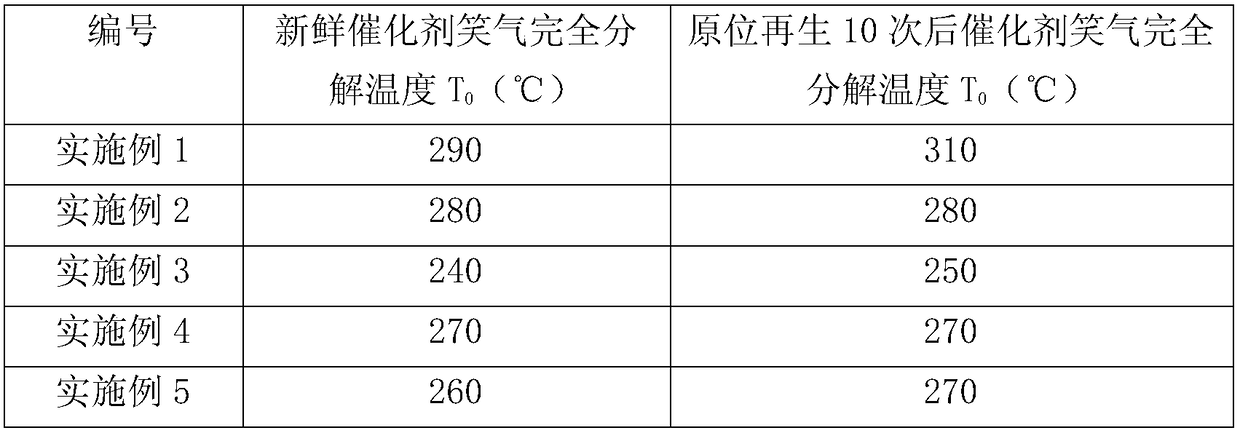

Embodiment 1

[0031] A preparation method for a catalyst for low-temperature decomposition of laughing gas, comprising the steps of:

[0032] a) Zinc nitrate, tin nitrate, and ammonium tungstate were mixed at a molar ratio of 0.2:0.45:0.35 and dissolved in methanol to prepare a mixed solution with a mass fraction of 5%, and the mixed solution was stirred at room temperature for 4 hours.

[0033] b) Immerse the fumed silica in the prepared sulfuric acid solution with a mass fraction of 5%, ultrasonically treat it for 6 minutes, wash with pure water until the pH is 6-7, and dry it in an oven at 90°C for later use.

[0034] c) Mix the mixed solution prepared in step a) with the carrier treated in step b) according to the mass ratio of 1:1, let it stand for 4 hours, dry it in an oven at 90°C, and then bake it in a muffle furnace at 300°C for 5 hours .

[0035] A kind of in-situ regeneration method of the laughing gas low-temperature decomposition catalyst prepared by the above method, comprisi...

Embodiment 2

[0040] A preparation method for a catalyst for low-temperature decomposition of laughing gas, comprising the steps of:

[0041] a) Ferric nitrate, cadmium nitrate, and chromium nitrate were mixed at a molar ratio of 0.4:0.45:0.15 and dissolved in ethanol to prepare a mixed solution with a mass fraction of 10%, and the mixed solution was stirred at room temperature for 10 h.

[0042] b) Immerse the ZSM-5 molecular sieve in the prepared hydrochloric acid solution with a mass fraction of 10%, ultrasonically treat it for 12 minutes, wash it with pure water until the pH is 6-7, and dry it in an oven at 110°C for later use.

[0043] c) Mix the mixed solution prepared in step a) with the carrier treated in step b) at a mass ratio of 1:1, let it stand for 10 hours, dry it in an oven at 100°C, and then bake it in a muffle furnace at 800°C for 12 hours .

[0044] A kind of in-situ regeneration method of the laughing gas low-temperature decomposition catalyst prepared by the above metho...

Embodiment 3

[0049] A preparation method for a catalyst for low-temperature decomposition of laughing gas, comprising the steps of:

[0050] a) molybdenum nitrate, manganese nitrate, cerium nitrate, ferric nitrate are mixed in molar ratio 0.4:0.35:0.1:0.15 and dissolved in isopropanol to prepare a mixed solution with a mass fraction of 8%, and mix the mixed solution at room temperature Stir and place for 6h.

[0051] b) Immerse the TS-1 molecular sieve in the prepared hydrochloric acid solution with a mass fraction of 8%, ultrasonically treat it for 10 minutes, wash it with pure water until the pH is 6-7, and dry it in an oven at 110°C for later use.

[0052] c) Mix the mixed solution prepared in step a) with the carrier treated in step b) at a mass ratio of 1:1, let it stand for 8 hours, dry it in an oven at 105°C, and then bake it in a muffle furnace at 600°C for 10 hours.

[0053] A method for in-situ regeneration of the nitrous oxide air deep oxidation catalyst prepared by the above m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com