Laminated tubular product for high-rise water drainage and manufacturing method thereof

A technology of laminated pipe and high-rise, applied in the field of laminated pipe for high-rise drainage and its preparation, can solve the problems of poor thermal stability of PVC resin, harsh processing conditions, poor low temperature resistance, etc., to overcome melt fracture and shortening. Plasticizing time, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

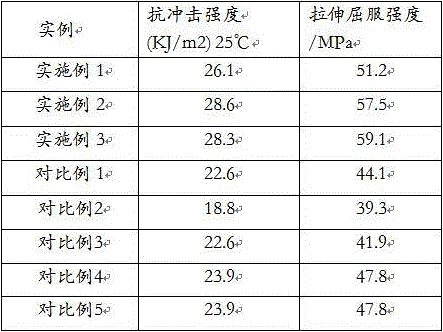

Examples

Embodiment 1

[0069] A laminated pipe for high-rise drainage, which consists of the following components in terms of mass fraction:

[0070] 60 parts of polyvinyl chloride resin;

[0071] 2 parts of organotin stabilizer;

[0072] 1 part stearic acid;

[0073] 2 parts of modified ACR;

[0074] 2 parts of titanium dioxide;

[0075] 2 parts of modified nano calcium carbonate;

[0076] Brightener 0.5;

[0077] 0.5 parts of MBS resin;

[0078] Among them, the organic tin stabilizer can be one of maleate, mercaptide, and mercaptan fatty acid salt; the polyvinyl chloride resin model is ethylene hair SG-5 resin;

[0079] The preparation of MBS resin in the raw material comprises the following steps:

[0080] Add soft water, emulsifier, and monomer into the reaction kettle and stir, then add potassium persulfate or ammonium persulfate initiator to initiate the reaction. The reaction occurs at a temperature of 90°C and a stirring speed of 200r / min. After the reaction is completed, the temperat...

Embodiment 2

[0093] A laminated pipe for high-rise drainage, which consists of the following components in terms of mass fraction:

[0094] 70 parts of polyvinyl chloride resin;

[0095] 3 parts of stabilizer;

[0096] 3 parts stearic acid;

[0097] 5 copies of modified ACR;

[0098] 5 parts of titanium dioxide;

[0099] 6 parts of modified nano calcium carbonate;

[0100] Brightener 0.8;

[0101] 1.3 parts of MBS resin;

[0102] Wherein the organotin stabilizer can be one of tribasic lead sulfate, dibasic lead phosphite, and lead stearate;

[0103] The preparation of described MBS resin comprises the following steps:

[0104] Add soft water, emulsifier, and monomer into the reaction kettle, stir, and then add potassium persulfate or ammonium persulfate initiator to initiate the reaction. The reaction occurs at a temperature of 110°C and a stirring speed of 250r / min. After the reaction is completed, the temperature is lowered to obtain MBS. The intermediate emulsion is then spray-d...

Embodiment 3

[0117] A laminated pipe for high-rise drainage, which consists of the following components in terms of mass fraction:

[0118] 80 parts of polyvinyl chloride resin;

[0119] 5 parts of stabilizer;

[0120] 5 parts of stearic acid;

[0121] 8 parts of modified ACR;

[0122] 8 parts of titanium dioxide;

[0123] 6 parts of modified nano calcium carbonate;

[0124] Brightener 1;

[0125] 2 parts of MBS resin;

[0126] The preparation of described MBS resin comprises the following steps:

[0127] Add soft water, emulsifier, and monomer into the reaction kettle and stir, and then add potassium persulfate or ammonium persulfate initiator to initiate the reaction. The reaction occurs at a temperature of 120°C and a stirring speed of 300r / min. After the reaction is completed, the temperature is lowered to obtain MBS. The intermediate emulsion is then spray-dried to obtain the finished product MBS resin powder; the emulsifier is sodium allyloxy hydroxypropyl sulfonate; the monom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com