Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

A graphene, thermal power plant technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of short service life, low durability and thermal stability of anti-corrosion coatings, deformation of anti-corrosion coatings, etc. Effects of stability and durability, enhanced sag resistance, improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

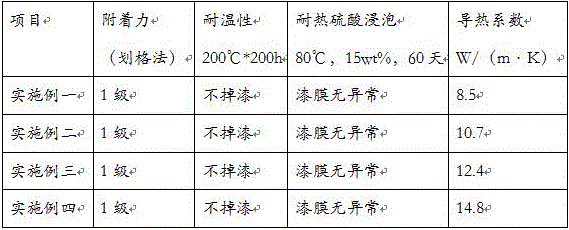

Examples

Embodiment 1

[0038] A kind of preparation method of graphene coating for desulfurization chimney anticorrosion of thermal power plant, specifically comprises the following steps:

[0039] Step 1. Blend graphene with a thickness of 20nm and a layer number of 10 layers with first-grade absolute ethanol in a ratio of 1:30 by mass in a blender and fully stir for 40 minutes at a stirring speed of 800 rad / min. Then add 0.5wt% silane coupling agent KH-550 and continue to stir for 20 minutes until it is evenly stirred. After stirring evenly, put the mixture into an ultrasonic emulsification disperser for full dispersion. The dispersion time is 50 minutes. Finally, take out the mixture and put it in an oven for drying Dry to obtain component A, wherein the operating frequency of the ultrasonic emulsification disperser is 40KHz, and the operating temperature is 30°C;

[0040] Step 2, filler preparation, weigh sericite powder and boron nitride powder according to the mass ratio of 5:7, place sericite...

Embodiment 2

[0047] Embodiment two is identical with embodiment one, and its difference is, a kind of thermal power plant desulfurization chimney anticorrosion graphene coating preparation method specifically comprises the following steps:

[0048] Step 1. Blend graphene with a thickness of 30nm and a layer number of 15 layers with primary anhydrous ethanol in a ratio of 0.5:30 by mass in a blender and fully stir for 50min at a stirring speed of 800rad / min. Then add 0.5wt% silane coupling agent KH-550 and continue to stir for 25 minutes until it is evenly stirred. After stirring evenly, put the mixture into an ultrasonic emulsification disperser for full dispersion. The dispersion time is 50 minutes. Finally, take out the mixture and put it in an oven for drying Dry to obtain component A, wherein the operating frequency of the ultrasonic emulsification disperser is 60KHz, and the operating temperature is 30°C.

[0049] Step 2, filler preparation, weigh mica powder and boron nitride powder ...

Embodiment 3

[0056] Embodiment three is identical with embodiment one and embodiment two, and its difference is that, a kind of preparation method of graphene coating for desulfurization chimney anticorrosion of thermal power plant specifically comprises the following steps:

[0057] Step 1. Blend graphene with a thickness of 50nm and a layer number of 20 layers with first-grade absolute ethanol in a ratio of 0.7:30 by mass in a blender and fully stir for 60 minutes at a stirring speed of 800 rad / min. Then add 0.5wt% silane coupling agent KH-550 and continue to stir for 30 minutes until it is evenly stirred. After stirring evenly, put the mixture into an ultrasonic emulsification disperser for full dispersion. The dispersion time is 60 minutes. Finally, take out the mixture and put it in an oven for drying Dry to obtain component A, wherein the operating frequency of the ultrasonic emulsification disperser is 50KHz, and the operating temperature is 50°C.

[0058] Step 2, filler preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com