Polyurethane foam loaded with metal-organic framework nanocrystals and its preparation and application

A metal-organic framework and polyurethane foam technology, which is applied in the preparation of organic compounds, organic chemistry, and carboxylic acid nitrile preparation, to overcome processing difficulties, have great application prospects, and increase the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Metal Organic Framework UiO-66-NH 2 Synthesis

[0055] Dissolve the organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, and acetic acid in N,N-dimethylformamide solvent, keep the temperature at 120°C for 24 hours, and cool down to room temperature to obtain light yellow nano-sized crystals, centrifuge, Drying; wherein the ratio of organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, acetic acid and N,N-dimethylformamide solvent addition is 0.04mmol: 0.04mmol: 2mmol: 1.6ml, the obtained crystal See in description figure 1 .

Embodiment 2

[0056] Example 2 metal organic framework MIL-101-NH 2 -Synthesis of (Fe)

[0057] The organic ligand 2-aminoterephthalic acid (1.09g, 6mmol) and ferric chloride hexahydrate (1.08g, 4mmol) were dissolved in 20mL DMF, placed in a crystallization axe, and kept at 110°C for 16h. Cool down to room temperature to obtain gray nanoscale crystals, centrifuge, wash with DMF and ethanol in turn, and dry at 120 degrees Celsius for 24 hours to obtain MIL-101-NH 2 -(Fe) crystalline powder, XRD results see figure 2 .

Embodiment 3

[0058] The synthesis of embodiment 3 polyether diol type polyurethane prepolymer

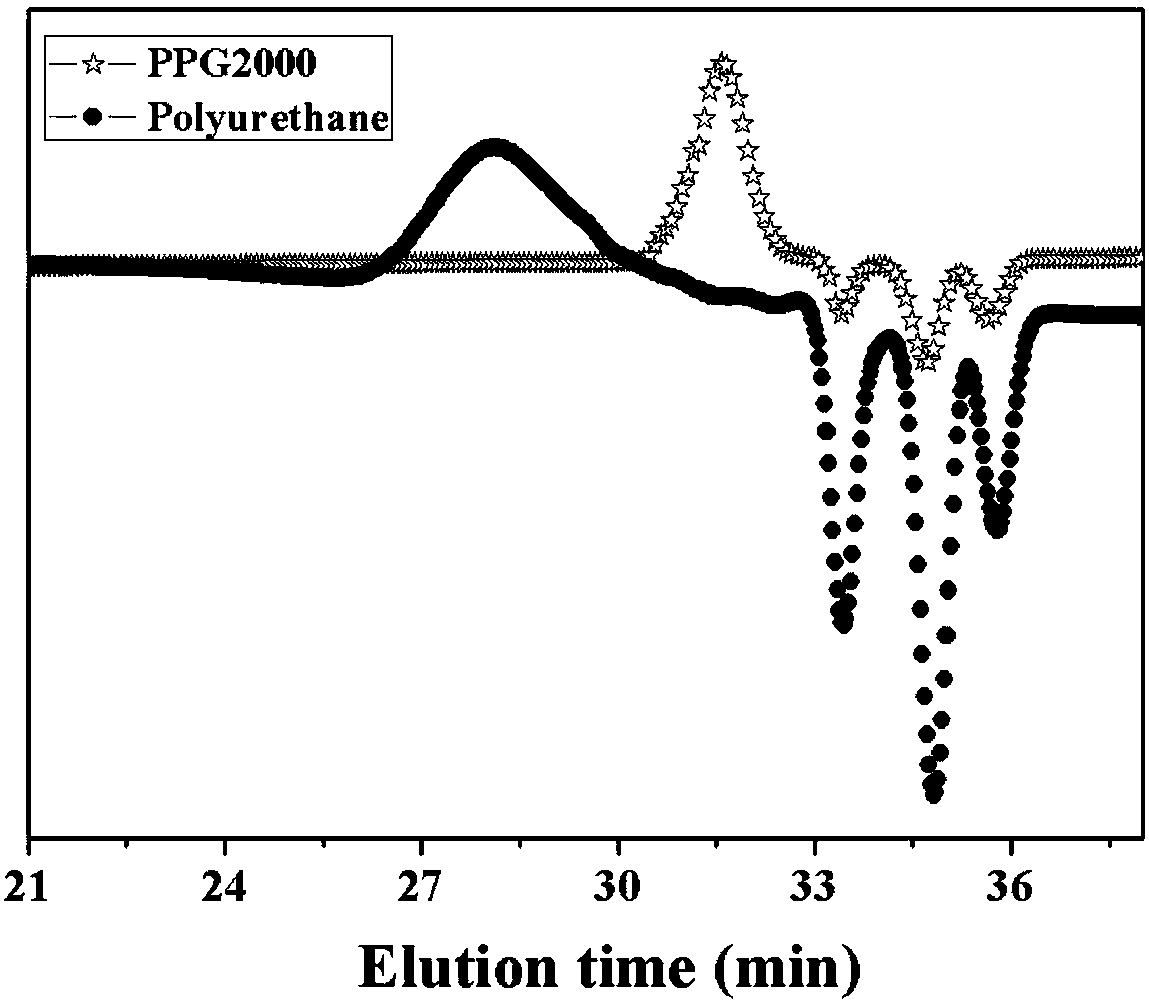

[0059] Add 37g of 4,4-diphenylmethane diisocyanate (MDI) and 63g of PPO (polypropylene oxide) with a molecular weight of 2000 into the reaction vessel in sequence, stir at 80°C, and react at constant temperature for 4 hours, then stop Heating, removing unreacted small molecules by vacuum distillation to obtain a prepolymer with NCO=10-11, viscosity 2000-3000mPa.s, GPC curve see image 3 , see the NMR spectrum Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com