Flame-retarding, acid-alkali-resisting wear-resisting fire hose material

A fire hose, acid and alkali resistance technology, applied in the field of fire protection, can solve the problems of heat damage to the fire hose, and achieve the effect of superior flame retardant and improved product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

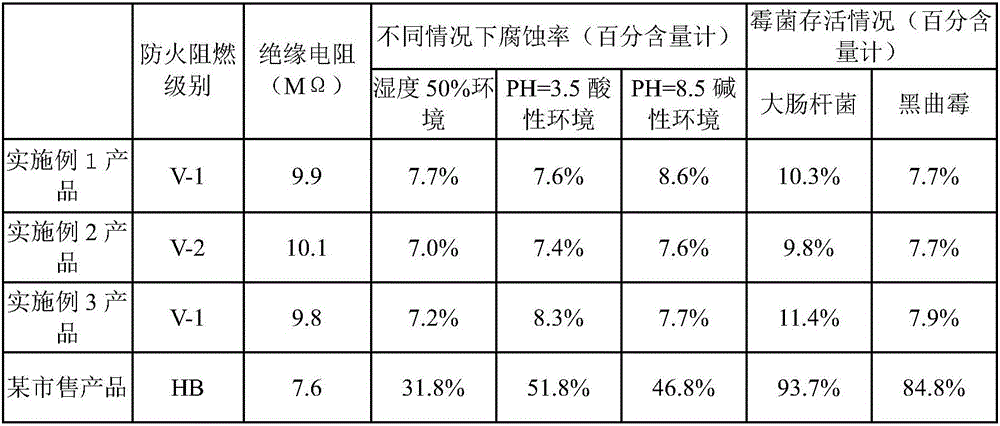

Embodiment 1

[0016] The flame-retardant acid and alkali-resistant wear-resistant fire-fighting hose material in this embodiment is composed of the following parts by mass: 22 parts of rosin resin, 20 parts of p-tert-octylphenol formaldehyde resin, 20 parts of amino resin, and polyethylene Wax emulsion 18 parts, tall oil fatty acid 20 parts, butyl acetate 20 parts, amyl propionate 18 parts, diethylene glycol ethyl ether 20 parts, dimethyl fumarate 20 parts, sodium perborate 18 parts, imidazoline 18 parts, 18 parts of ammonium fluorosilicate, 20 parts of guanidine phosphate powder, 18 parts of phenyltriethoxysilane, 16 parts of sodium pyrophosphate, 20 parts of chrome green, 18 parts of chromium chloride, 16 parts of menthol, chromic acid 18 parts of barium powder, 16 parts of iron orthophosphate, 16 parts of triethylene glycol diisocaprylate, 16 parts of tricresol phosphate, 14 parts of decabromodiphenyl ether, 10 parts of nano magnesium hydroxide, 8 parts of lignin, 8 parts of morpholine, 8...

Embodiment 2

[0022] The flame-retardant acid and alkali resistant wear-resistant fire hose material in this embodiment is composed of the following parts by mass: 24 parts of rosin resin, 22 parts of p-tert-octylphenol formaldehyde resin, 22 parts of amino resin, polyethylene 20 parts of wax emulsion, 22 parts of tall oil fatty acid, 22 parts of butyl acetate, 20 parts of amyl propionate, 22 parts of diethylene glycol ether, 22 parts of dimethyl fumarate, 20 parts of sodium perborate, imidazoline 20 parts, 20 parts of ammonium fluorosilicate, 22 parts of guanidine phosphate powder, 20 parts of phenyltriethoxysilane, 18 parts of sodium pyrophosphate, 22 parts of chrome green, 20 parts of chromium chloride, 18 parts of menthol, chromic acid 20 parts of barium powder, 18 parts of iron orthophosphate, 18 parts of triethylene glycol diisocaprylate, 18 parts of tricresol phosphate, 16 parts of decabromodiphenyl ether, 12 parts of nano magnesium hydroxide, 10 parts of lignin, 10 parts of morpholin...

Embodiment 3

[0028] The flame-retardant acid and alkali resistant wear-resistant fire hose material in this embodiment is composed of the following parts by mass: 26 parts of rosin resin, 24 parts of p-tert-octylphenol formaldehyde resin, 24 parts of amino resin, and polyethylene 22 parts of wax emulsion, 24 parts of tall oil fatty acid, 24 parts of butyl acetate, 22 parts of pentyl propionate, 24 parts of diethylene glycol ethyl ether, 24 parts of dimethyl fumarate, 22 parts of sodium perborate, imidazoline 22 parts, 22 parts of ammonium fluorosilicate, 24 parts of guanidine phosphate powder, 22 parts of phenyltriethoxysilane, 20 parts of sodium pyrophosphate, 24 parts of chrome green, 22 parts of chromium chloride, 20 parts of menthol, chromic acid 22 parts of barium powder, 20 parts of iron orthophosphate, 20 parts of triethylene glycol diisocaprylate, 20 parts of tricresol phosphate, 18 parts of decabromodiphenyl ether, 14 parts of nano-magnesium hydroxide, 12 parts of lignin, 12 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com