High-temperature X8R type ceramic-capacitor dielectric material and preparation method thereof

A technology of ceramic capacitors and dielectric materials, applied in the direction of fixed capacitor dielectrics, capacitors, fixed capacitors, etc., can solve the problems of low working temperature range, low compressive strength, high dielectric loss, and achieve high working temperature range and high compressive strength. , the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

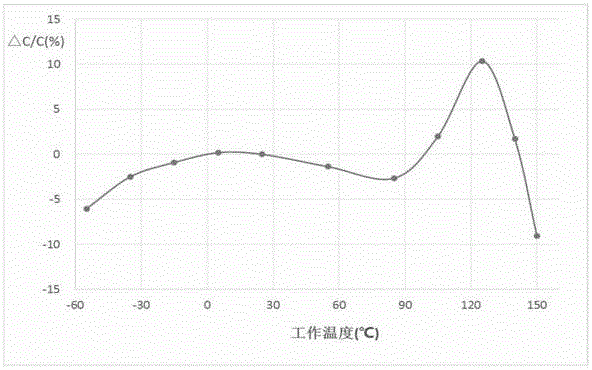

Image

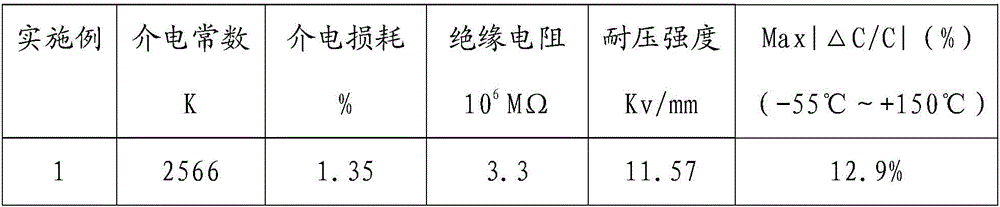

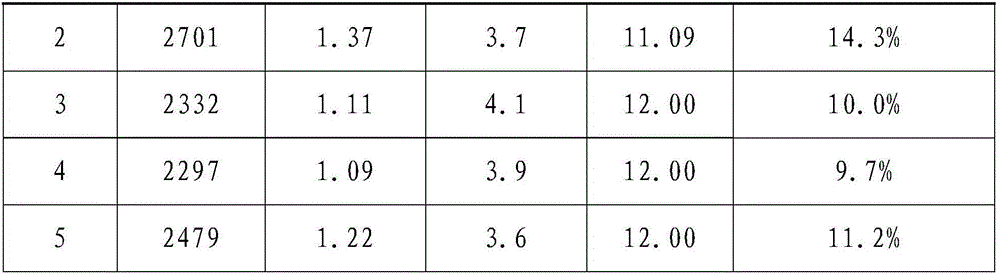

Examples

preparation example Construction

[0040] A method for preparing a high-temperature X8R type ceramic capacitor dielectric material, characterized in that it comprises the following steps:

[0041] Step 1, synthesizing the eutectic of barium titanate and bismuth sodium barium titanate after first synthesizing bismuth sodium barium titanate;

[0042] Step 2, synthesize the eutectic of oxides of niobium manganese and A, the atomic ratio of niobium to manganese is 6ˉ11, the atomic ratio of niobium to A element is 4.5ˉ8.5, and the atomic ratio of Nb to A is 4.5ˉ8.5. 2 o 5 , MnCO 3 , A oxide as raw material, wherein the A element is one or more of cobalt (Co), nickel (Ni), zinc (Zn), bismuth (Bi), etc., carry out batching, ball milling, drying, crushing, passing 40 Mesh standard screen, and then calcined at 900-1150°C for 2-6 hours to synthesize a co-melt of oxides of niobium-manganese and A;

[0043] Step 3, synthesis of silicon-lithium eutectic, by Li / Si atomic ratio=2ˉ4, with Li 2 CO 3 , SiO 2 As a raw mater...

specific Embodiment 1

[0050] Step 1, first synthesize bismuth sodium barium titanate and then synthesize the eutectic of barium titanate and bismuth sodium barium titanate, weigh 8.11g Ba(OH) respectively 2 ·8H 2 O, 10.68g Na 2 CO 3 , 46.96g Bi 2 o 3 , 34.25g TiO 2 , mixed ball milling, drying, crushing, passing through a 40-mesh standard sieve, and calcining at 850°C for 2 hours to synthesize bismuth sodium barium titanate; weigh 98g BaTiO 3 and 2g of bismuth sodium barium titanate synthesized in step ①, mixed with ball milling, dried, crushed, passed through a 40-mesh standard screen, and calcined at 1100°C for 3 hours to synthesize a eutectic product of barium titanate and bismuth sodium barium titanate;

[0051] Step 2, synthesize the eutectic of the oxide of niobium manganese and A, weigh 78g Nb respectively 2 o 5 , 10g MnCO 3 , 3gZnO, 9gCo 2 o 3 , mixing ball milling, drying, crushing, passing through a 40-mesh standard sieve, and calcining at 900°C for 2.5 hours to synthesize a nio...

specific Embodiment 2

[0056] Step 1, first synthesize bismuth sodium barium titanate and then synthesize the eutectic of barium titanate and bismuth sodium barium titanate, weigh 8.11g Ba(OH) respectively 2 ·8H 2 O, 10.68g Na 2 CO 3 , 46.96g Bi 2 o 3 , 34.25g TiO 2 , mixed ball milling, drying, crushing, passing through a 40-mesh standard sieve, and calcining at 900°C for 2 hours to synthesize bismuth sodium barium titanate, and weigh 97.5g BaTiO 3 and 2.5g of bismuth sodium barium titanate synthesized in step ①, mixed with ball milling, dried, crushed, passed through a 40-mesh standard screen, and calcined at 1090°C for 3 hours to synthesize a eutectic product of barium titanate and bismuth sodium barium titanate;

[0057] Step 2, synthesize the eutectic of the oxide of niobium manganese and A, weigh 80g Nb respectively 2 o 5 , 10g MnCO 3 , 10gCo 2 o 3 , mixing ball milling, drying, crushing, passing through a 40-mesh standard sieve, and calcining at 930°C for 2.5 hours to synthesize a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com