Compound semiconductor corrosion method

A compound and semiconductor technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of slow etching rate, time-consuming and energy-consuming oxidation process, inability to achieve partial etching, etc., to reduce roughness , the effect of precise control of etching rate and depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

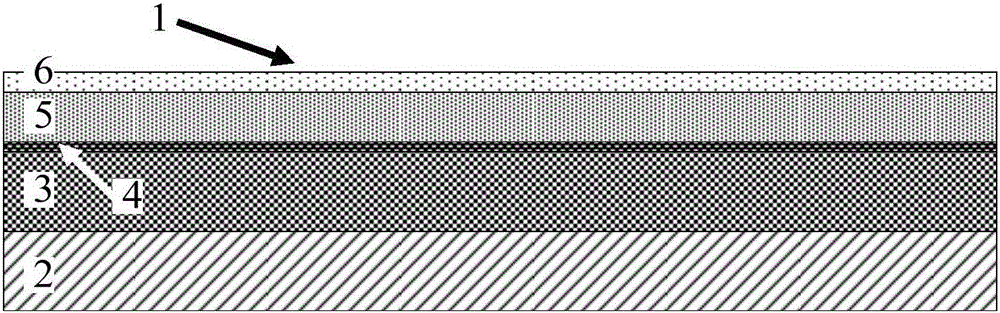

[0060] A kind of epitaxial wafer 1, the schematic diagram of its section structure is as figure 1 shown. The epitaxial wafer 1 includes a substrate 2 (sapphire substrate), a GaN buffer layer 3 (channel layer), a two-dimensional electron gas layer 4, an AlGaN barrier layer 5 (where the content of Al is adjustable) and a GaN buffer layer 5 from bottom to top. Layer 6.

[0061] The epitaxial wafer 1 is etched, and the etching method includes the following steps:

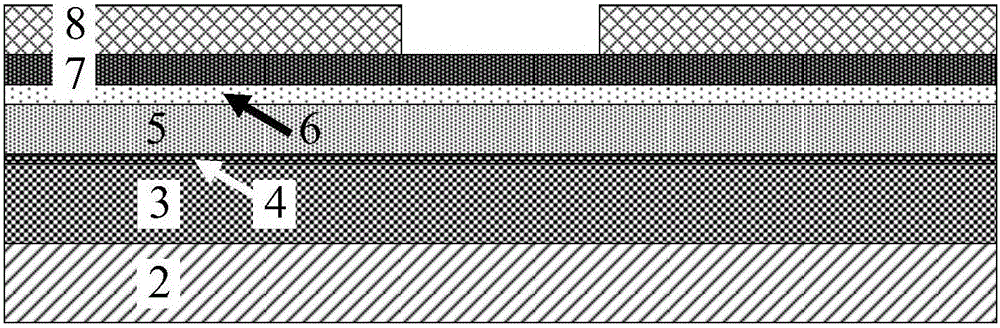

[0062] (1) Covering the mask layer 7 on the surface of the GaN layer 6, the material of the mask layer is selected from silicon oxide;

[0063] (2) Cover the photoresist layer on the surface of the mask layer 7, and obtain a patterned photoresist layer 8 by using a photolithography process;

[0064] (3) Obtaining a patterned mask layer by wet etching and / or dry etching;

[0065] (4) removing the patterned photoresist layer 8;

[0066] (5) Oxygen plasma generated by inductively coupled plasma-reactive ion etching sy...

Embodiment 2

[0081] An epitaxial wafer 1, which includes a substrate 2 (sapphire substrate), a GaN buffer layer 3 (channel layer), a two-dimensional electron gas layer 4 and an AlGaN barrier layer 5 from bottom to top.

[0082] The epitaxial wafer 1 is etched, and the etching method includes the following steps:

[0083] (1) covering the mask layer 7 on the surface of the AlGaN barrier layer 5, the material of the mask layer is selected from silicon nitride;

[0084] (2) Cover the photoresist layer on the surface of the mask layer 7, and obtain a patterned photoresist layer 8 by using a photolithography process;

[0085] (3) Obtain a patterned mask layer 7 by wet etching and / or dry etching;

[0086] (4) removing the patterned photoresist layer 8;

[0087] (5) Oxygen plasma generated by an inductively coupled plasma-reactive ion etching system is used to oxidize the exposed AlGaN barrier layer 5 to obtain an oxide layer 9, wherein, in the inductively coupled plasma-reactive ion etching sy...

Embodiment 3

[0091] A kind of epitaxial wafer 1, the schematic diagram of its section structure is as figure 1 shown. The epitaxial wafer 1 sequentially includes a substrate 2 (sapphire substrate), a GaN buffer layer 3, a two-dimensional electron gas layer 4, an AlGaN barrier layer 5 and a GaN capping layer from bottom to top.

[0092] The epitaxial wafer 1 is etched, and the etching method includes the following steps:

[0093] (1) covering the mask layer 7 on the surface of the GaN layer 6, the material of the mask layer is selected from aluminum;

[0094] (2) Cover the photoresist layer on the surface of the mask layer 7, and obtain a patterned photoresist layer 8 by using a photolithography process;

[0095] (3) Obtain a patterned mask layer 7 by wet etching and / or dry etching;

[0096] (4) removing the patterned photoresist layer 8;

[0097] (5) Oxygen plasma generated by inductively coupled plasma-reactive ion etching system is used to oxidize the exposed GaN layer 6 to obtain ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com