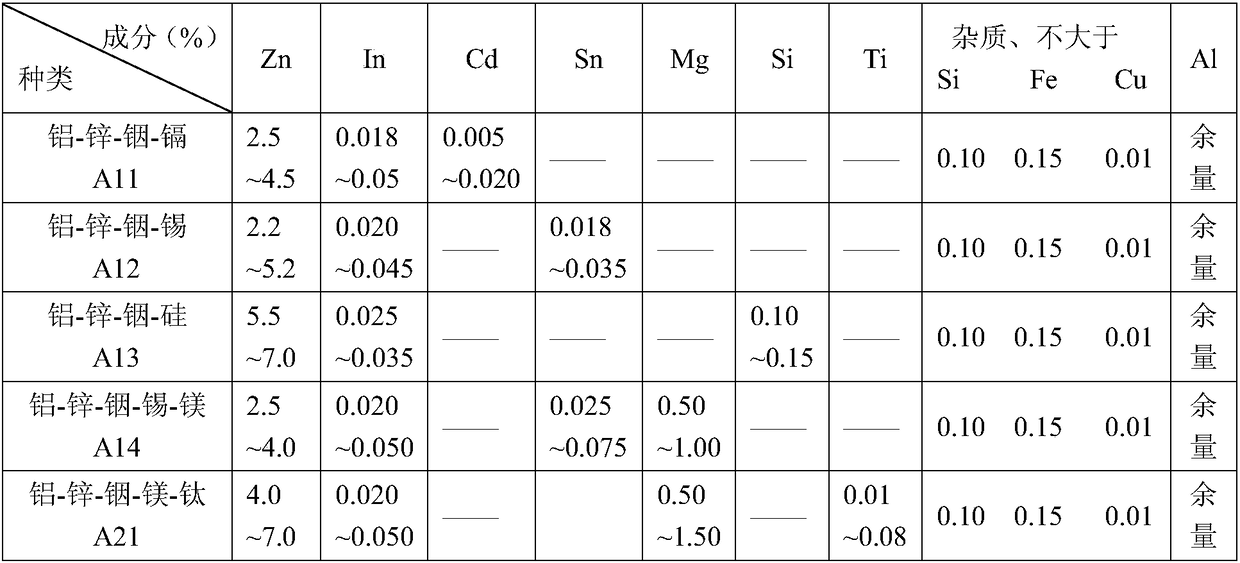

A kind of corrodible aluminum alloy material and preparation method thereof

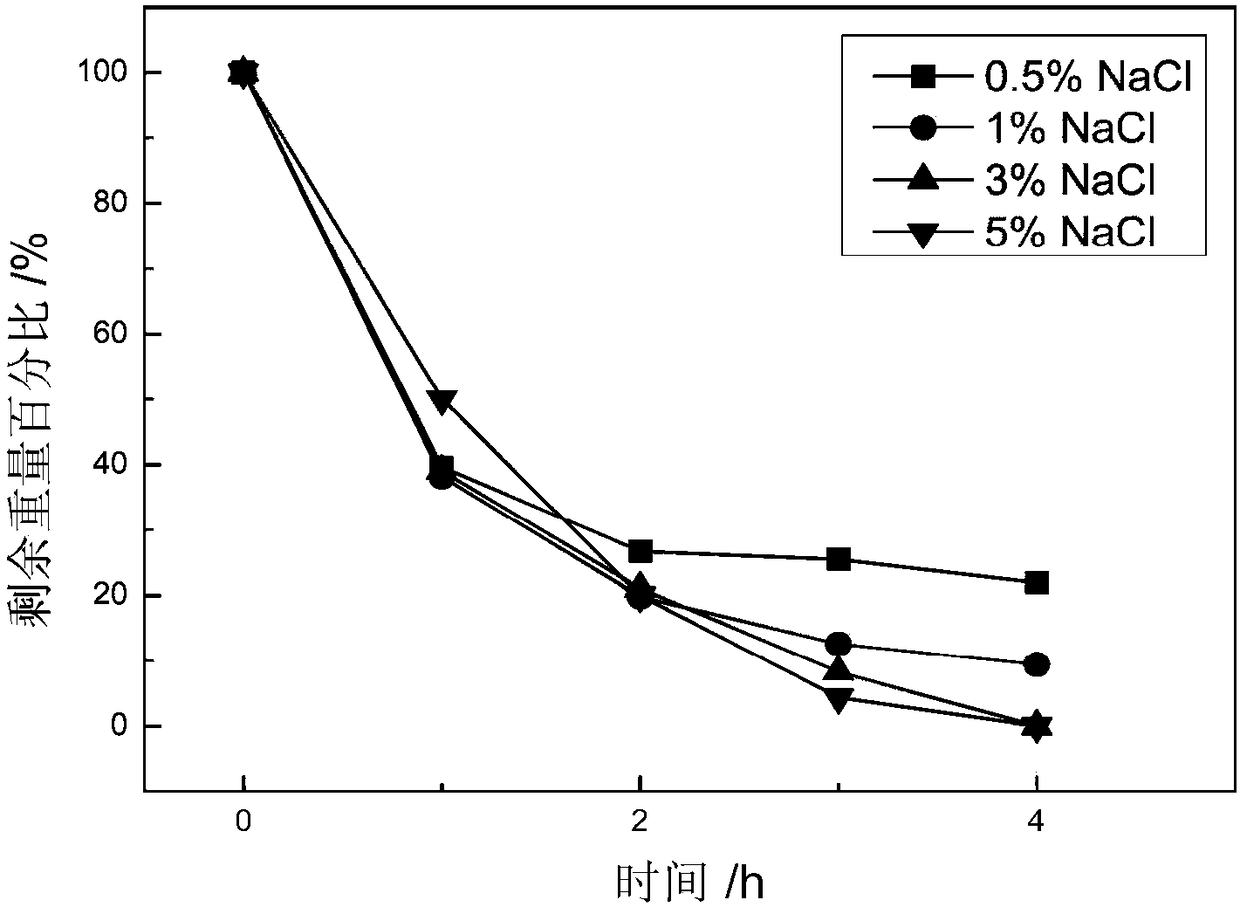

An aluminum alloy material and easy-to-corrosion technology, applied in the field of aluminum alloys, can solve problems such as failure to meet the use requirements and slow corrosion rate, and achieve the effects of fast corrosion rate, compact structure, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Chemical composition (mass fraction) of easily corroded aluminum alloy: 3.0% Zn, 2.0% Mg, 0.5% Ga, 0.3% In, 0.3% Sn, 0.55% Fe, 0.3% Mn, and the rest is Al.

[0022] Preparation method of easily corroded aluminum alloy:

[0023] 1) According to the mass percentage content of each element in the aluminum alloy material, configure 99.7% pure aluminum, 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium, 99.995% pure indium, Al-20 %Fe master alloy and Al-10%Mn master alloy.

[0024] 2) First, heat up and melt 99.7% pure aluminum, Al-20% Fe master alloy and Al-10% Mn master alloy; adjust the temperature of the aluminum alloy melt to 730°C, and use an iron bell jar to dry the dried flux The refining agent is pressed into the aluminum alloy melt for refining and purification, adding a mass percentage of 0.6%, and removing slag after refining; adding 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium and 99.995% % pure indium, le...

Embodiment 2

[0029] The chemical composition (mass fraction) of the easily corroded aluminum alloy: 7.0% Zn, 5.0% Mg, 5% Ga, 2% In, 0.1% Sn, 0.1% Fe, 0.1% Mn, and the rest is Al.

[0030] Preparation method of easily corroded aluminum alloy:

[0031] 1) According to the mass percentage content of each element in the aluminum alloy material, configure 99.7% pure aluminum, 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium, 99.995% pure indium, Al-20 %Fe master alloy and Al-10%Mn master alloy.

[0032] 2) First, heat up and melt 99.7% pure aluminum, Al-20% Fe master alloy and Al-10% Mn master alloy; adjust the temperature of the aluminum alloy melt to 750°C, use high-purity nitrogen for refining and degassing, and the refining is completed After removing slag; add 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium and 99.995% pure indium, let it stand for 20 minutes, check the composition of the alloy, and pour it after the composition is qual...

Embodiment 3

[0037] Chemical composition (mass fraction) of easily corroded aluminum alloy: 5.0% Zn, 3.5% Mg, 3% Ga, 1% In, 0.1% Sn, 0.1% Fe, 0.1% Mn, and the rest is Al.

[0038] Preparation method of easily corroded aluminum alloy:

[0039] 1) According to the mass percentage content of each element in the aluminum alloy material, configure 99.7% pure aluminum, 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium, 99.995% pure indium, Al-20 %Fe master alloy and Al-10%Mn master alloy.

[0040] 2) First, heat up and melt 99.7% pure aluminum, Al-20% Fe master alloy and Al-10% Mn master alloy; adjust the temperature of the aluminum alloy melt to 740°C, and use 0.6% hexachloroethane for refining and degassing After refining, remove slag; add 99.9% pure zinc, 99.8% pure magnesium, 99.8% pure tin, 99.99% pure gallium and 99.995% pure indium, let it stand for 20 minutes, check the alloy composition, and pour it after the composition is qualified.

[0041] 3) Sand casting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com