A kind of iron-based material with surface patterned deposition metal and its preparation method and application

An iron-based material and surface pattern technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of accelerated corrosion of iron-based materials, no disclosure, etc., to achieve accelerated corrosion and controllable corrosion rate , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

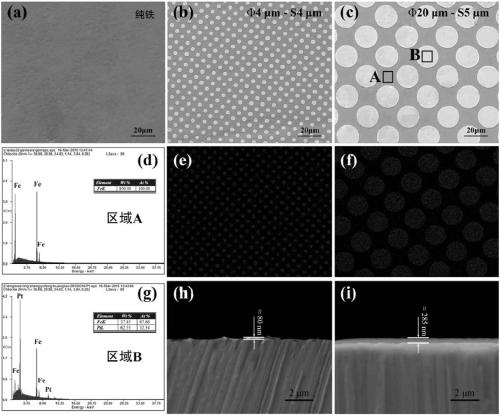

[0028] Example 1. Preparation of iron-based materials by depositing Pt disk arrays on the surface of pure iron

[0029] The test raw materials are pure Fe (purity: 99.95wt.%) and pure Pt (purity: 99.99wt.%).

[0030] Example 1 designed and prepared two iron-based materials with the size and arrangement of Pt discs on the surface, including Φ20 μm × S5 μm (Φ20 μm means that the diameter of the Pt electrode disc is 20 μm, and S5 μm means that the distance between the two nearest adjacent Pt discs is 5 μm ) and Φ4μm×S4μm, and the Pt disk was plated on the surface of pure iron by photolithography technology and electron beam evaporation technology. The ratio of the surface area of Pt disk to pure iron was 0.50265 and 0.19635, respectively.

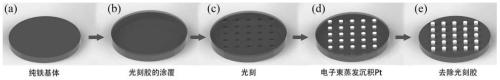

[0031] The preparation process of the Pt disk pattern is as follows figure 1 As shown, the specific steps are as follows:

[0032] (1) Polish the pure iron sheet, on the polished pure iron sheet (Φ75×1mm 2 ) is spin-coated with a layer of...

Embodiment 2

[0036] Embodiment 2, corrosion performance

[0037]The Pt disk patterned pure iron cold cut that embodiment 1 makes is 10 * 10 * 2mm 3 block sample, and then in Hank’s simulated body fluid (NaCl 8.0g, CaCl 2 0.14g, KCl 0.4g, NaHCO 3 0.35g, glucose 1.0g, MgCl 2 ·6H 2 O 0.1g,Na 2 HPO 4 2H 2 O 0.06g, KH 2 PO 4 0.06g, MgSO 4 ·7H 2 O 0.06g was dissolved in 1L deionized water) to carry out electrochemical test and immersion test to detect the corrosion rate of the material, with unpatterned pure iron as a comparison (measured by experiment, pure iron is in the Hank's simulated body fluid with a temperature of 37 ℃ The corrosion potential of platinum is -0.699V, the corrosion potential of platinum is 0.20V, and the corrosion potential difference between platinum and iron is 0.899V).

[0038] The electrochemical parameters of the Pt disc patterned iron-based material prepared in Example 1 and the corrosion rate calculated by two detection methods are shown in Table 1. As ...

Embodiment 3

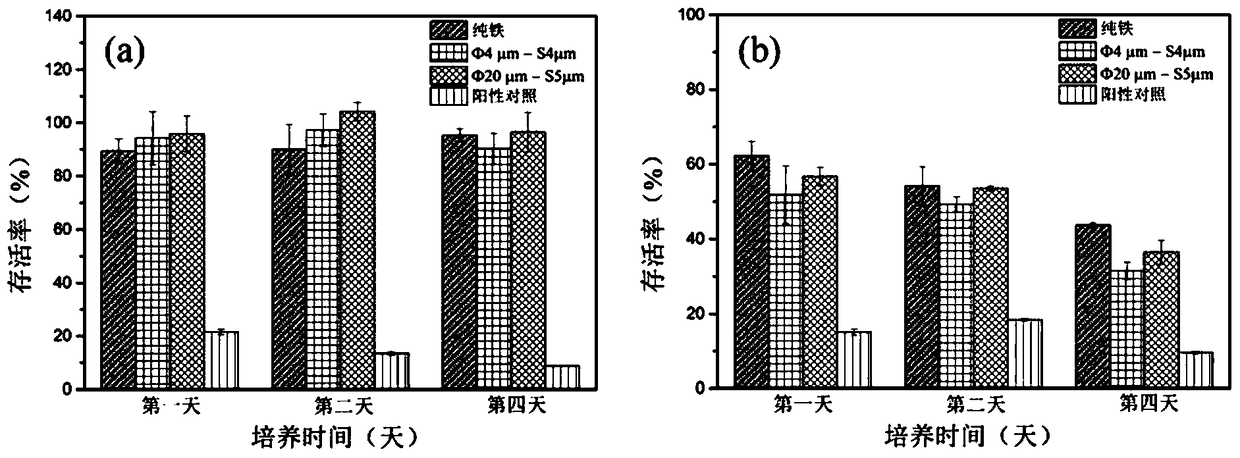

[0043] Embodiment 3, the biocompatibility of patterned iron-based material

[0044] Prepare the experimental sample according to the method in Example 1, and compare it with unpatterned pure iron. 2 ·ml -1 The standard extraction extract was used for cytotoxicity experiments of vascular smooth muscle cells VSMC and endothelial cells EA.hy-926. In addition, the sample was soaked in 10 mL of physiological saline containing 0.2 ml of diluted human blood (normal saline:human blood (volume)=5:4) for 1 hour, and the hemolysis rate of the material was tested.

[0045] The results of the cell survival rate and Pt disk patterned pure iron hemolysis rate relative to the negative control after culture are as follows: image 3 and Figure 4 shown by image 3 It can be seen that after culturing patterned iron-based materials and unpatterned pure iron extracts for 1, 2 and 4 days, the survival rate of VSMC cells decreased with the prolongation of culture time, while EA.hy-926 The cells...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com