Waterborne epoxy paint for protective treatment of cement concrete basal plane, and preparation method of waterborne epoxy paint

A technology of water-based epoxy coatings and water-based epoxy resins, which is applied in epoxy resin coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., and can solve problems such as flammability and explosion of organic solvents, environmental pollution, and performance gaps. Achieve the effects of excellent hardness and impact resistance, cost reduction, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

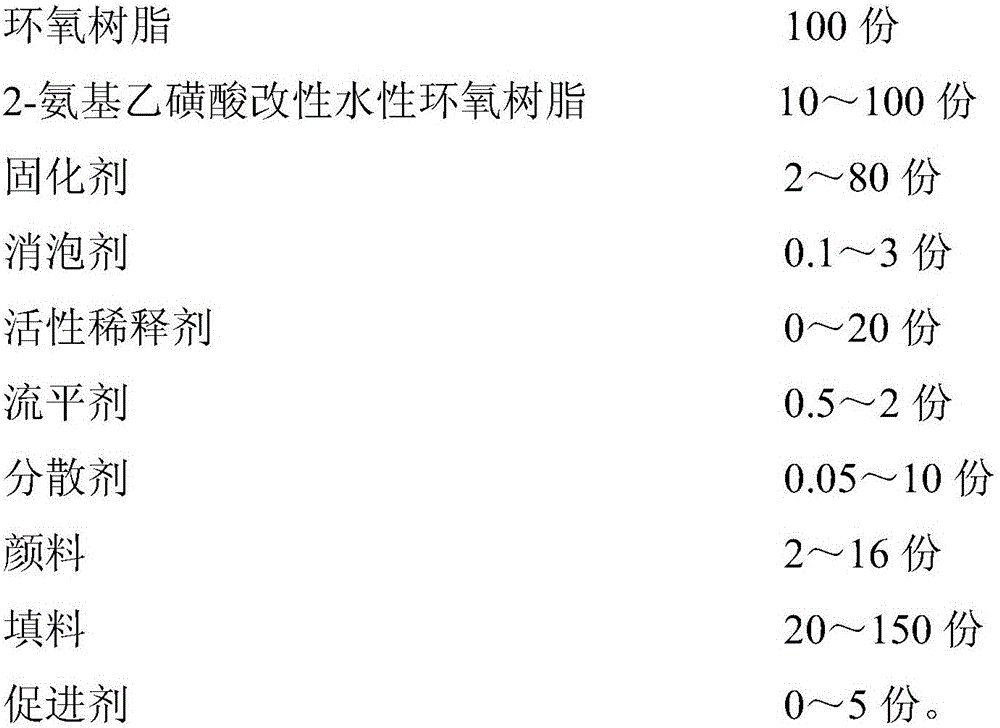

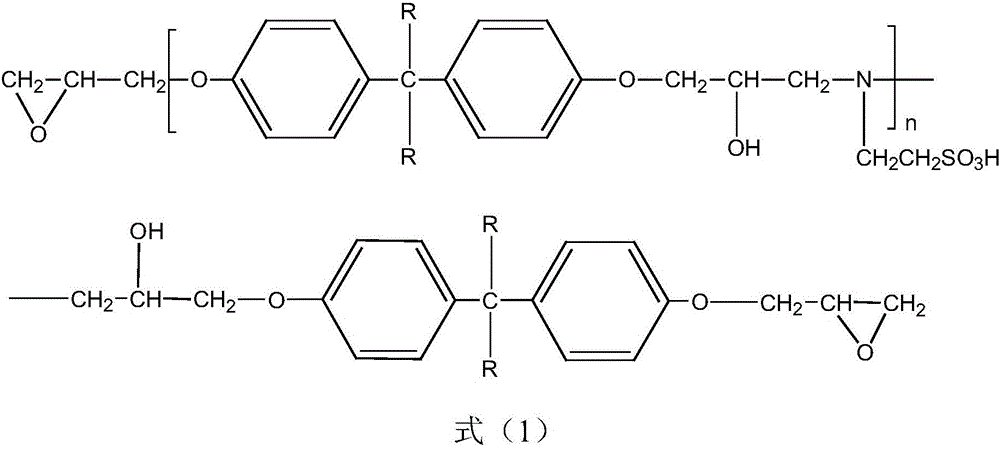

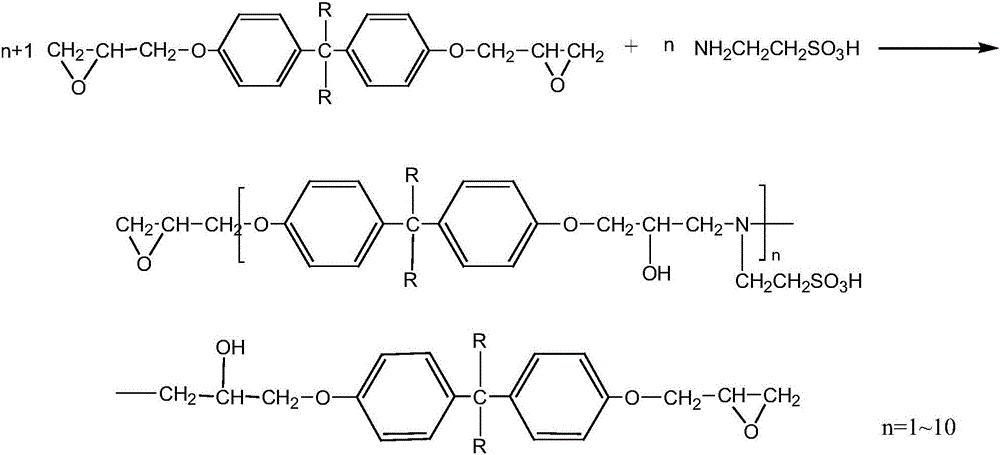

[0041] (1) Mix 100g of E-03 epoxy resin, 3g of 2-aminoethanesulfonic acid, 40g of deionized water and 1g of surfactant F8a into a three-necked bottle, and react for 5 hours at a temperature of 25°C. A water-based epoxy resin with a solid content of 70% can be obtained.

[0042] (2) Disperse 10g of modified water-based epoxy resin synthesized in step (1), 100g of E-03 epoxy resin, 0.1g of defoamer BYK06660.1g, 10g of propylene oxide butyl ether, and 0.8g of leveling agent EFKA3777 Agent BYK-P104 0.05g, titanium dioxide 16g, kaolin 20g, put in a strong mixer and mix evenly; then add 2g of DA-134 ketimine curing agent, mix evenly with a strong mixer, and get the water-based cement concrete base surface protection treatment. epoxy paint. After curing at room temperature for 14 days, measure the hardness with the standard GB / T6739-1996 (pencil hardness test method), the pencil hardness of the floor coating is 2H; use the standard GB / T 1768-2006 to measure the wear resistance, the ...

Embodiment 2

[0044](1) 100g E-51 epoxy resin, 14g 2-aminoethanesulfonic acid, 100g deionized water and 2g surfactant L-44 are mixed and dropped into a three-necked bottle, and reacted for 6 hours at a temperature of 30°C. Complete can obtain the waterborne epoxy resin that solid content is 50%.

[0045] (2) 30g of modified water-based epoxy resin synthesized in step (1), 100g of E-51 epoxy resin, 0.8g of defoamer BYK066, 5g of C12-C14 fatty alcohol glycidyl ether, and 1.6g of leveling agent EFKA3777 , dispersant BYK163 8g, carbon black 10g, talcum powder 150g, put in a strong mixer and mix evenly; then add 12g of diethylenetriamine, mix evenly with a strong mixer, and then get the water-based epoxy coating for cement concrete base surface protection treatment. After curing at room temperature for 14 days, the pencil hardness of the floor coating obtained by testing is 3H; the abrasion resistance is 0.023, and the impact resistance is grade II, and the 1000g steel ball has no cracks and no ...

Embodiment 3

[0047] (1) Mix 100g E-54 epoxy resin, 34g 2-aminoethanesulfonic acid, 150g deionized water and 2g surfactant tetrabutylammonium bromide into a three-necked bottle, and react at a temperature of 35°C for 6 Hours, the reaction is completed to obtain a water-based epoxy resin with a solid content of 45%.

[0048] (2) 30g of modified water-based epoxy resin synthesized in step (1), 100g of E-54 epoxy resin, 1.2g of polysiloxane defoamer BYK066, 10g of butanol, 0.5g of leveling agent EFKA3777, Dispersant BYK163 10g, chrome yellow 2g, quartz sand 40g, 2-methylimidazole 1g, mix well in a strong mixer; then add N-AEP curing agent 32g, mix well with a strong mixer, and get the cement concrete base surface protection Treatment with water-based epoxy coatings. After curing at room temperature for 14 days, the pencil hardness of the floor coating obtained by testing is 3H; the abrasion resistance is 0.021, and the impact resistance is grade II, and the 1000g steel ball has no cracks and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com