Polyphenylene-oxide-filled (PPO-filled) aligned carbon nanotube bundle (ACNTB)/thermosetting resin and preparation method thereof

A technology of oriented carbon nanotubes and polyphenylene ether, applied in the field of polymer composite material preparation, to achieve the effects of increasing interface effects, excellent heat resistance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of ACNTB@PPO

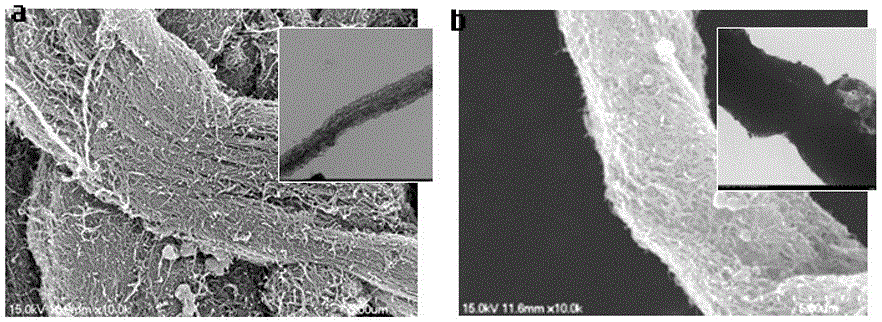

[0025] Dissolve 2g of vinyl-terminated PPO with a number average molecular weight of 2200 in about 90g of toluene solution to obtain a PPO solution. Add 1.5g of ACNTB to the solution, stir and defoam under vacuum at room temperature. Under capillary force and vacuum pressure, PPO The solution will penetrate into the pores between the ACNTB tube and the tube. As the solvent evaporates, the solution becomes viscous (5Pa·s), add 200g ethanol, stir for 2h, filter the solution and dry to obtain polyphenylene ether filled oriented carbon nano The tube bundle particles are marked as ACNTB@PPO particle powder, and the PPO content in the obtained ACNTB@PPO particles is about 51wt%. figure 1 Scanning electron microscope (SEM) and transmission electron microscope (TEM) pictures of ACNTB and ACNTB@PPO particles, a is ACNTB, b is ACNTB@PPO particle. Compared figure 1 a and b, it can be seen that the gap between the carbon tube and the carbon tube in the A...

Embodiment 2

[0032] Mix 50g of CE (bisphenol A cyanate ester) and 0.5g of diaminodiphenyl sulfone, heat and prepolymerize at 145°C and stir for 1.5h, then add 2.5g of N,N'-4,4'-diphenylmethane The ACNTB@PPO particles prepared in Example 1 and 1g ACNTB@PPO particles were heated and pre-polymerized at 145°C and stirred for 1 hour to obtain the ACNTB@PPO / CE pre-polymerization system; the pre-polymerization system was injected into the mold preheated at 145°C, After vacuum degassing at 150-160℃, solidify according to temperature program 160℃ / 2h+180℃ / 2h+200℃ / 2h+220℃ / 2h, and obtain ACNTB@PPO / CE composite material system after natural cooling .

[0033] In order to compare the performance, the same curing process was used to prepare the CE resin composite material (ACNTB / PPO / CE) of ACNTB and PPO with the same content as the ACNTB@PPO / CE composite material. Table 2 lists the mechanical properties, glass transition temperature and limited oxygen index of the ACNTB@PPO / CE composite system. Comparing ...

Embodiment 3

[0037] (1) Preparation of ACNTB@PPO

[0038] Calculated by weight, dissolve 2g vinyl-terminated PPO with a number average molecular weight of 1100 in about 90g toluene solution to obtain a toluene solution of PPO. Add 2g ACNTB to the solution. Stir and vacuum degas at room temperature. Under vacuum pressure, the PPO The toluene solution will effectively penetrate into the pores between the ACNTB tubes. As the solvent evaporates, the solution becomes viscous (20Pa·s). Add about 200g of ethanol, stir for 2h, filter the solution and dry to obtain ACNTB@PPO particle powder. The PPO content in the obtained ACNTB@PPO particles is about 40wt%.

[0039] (2) Preparation of ACNTB@PPO / CE composite material

[0040] Heat 50g of CE (bisphenol E cyanate ester) at 145°C for 2h to prepolymerize and stir, then add 1.5g of N,N'-4,4'-diphenyl ether bismaleimide and 2gACNTB@PPO particles, and then Heat and pre-polymerize at 145°C and stir for 1 hour to obtain ACNTB@PPO / CE pre-polymerized system; injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com