High-property emulsion paint

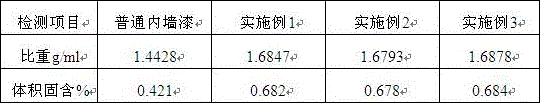

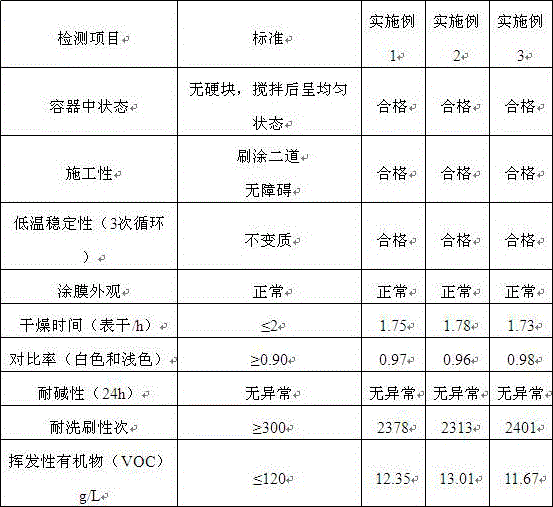

A latex paint, high-performance technology, applied in latex paint, anti-corrosion coatings, coatings, etc., can solve the problems of weak adhesion of the coating film, high VOC, low volume solid content, etc., to increase the thickness of the paint film, the adhesion of the coating film Strong force and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described high-performance latex paint, comprises the following steps:

[0029] S1: Add butyl acrylate, methyl methacrylate, superfine wollastonite, titanium dioxide, montmorillonite, white cement, potato modified starch, boron fiber, polyester fiber, hydroxypropyl methylcellulose, glycerin Alcohol, dispersant NC, and 235-320 parts of water are mixed, and dispersed at a temperature of 53-58°C and a rotation speed of 500-800r / min for 0.4-0.9h to obtain a mixture a;

[0030] S2: Add sodium dodecylbenzenesulfonate, stearic acid, leveling agent DSX2000, wetting agent CF-10, colorless cobalt, platinum catalyst, azobisisobutyric acid to the mixture a prepared in step S1 (Ethylene glycol acrylate), polyoxyethylene polyoxypropanolamine ether, paraffin wax emulsifier, continue to disperse at a temperature of 65-72°C, a microwave power of 120-150W, and a rotation speed of 200-400r / min for 0.8-1.3 h, making mixture b;

[0031] S3: sand-mill the mixture ...

Embodiment 1

[0036] A kind of high-performance latex paint, by weight, comprises the following raw materials: 34 parts of butadiene-styrene emulsion, 28 parts of acrylate emulsion, 22 parts of nano-titanium oxide concentrated slurry, 14 parts of butyl acrylate, methyl methacrylate 10 parts of ester, 9 parts of superfine wollastonite, 5 parts of titanium dioxide, 7 parts of montmorillonite, 8 parts of white cement, 14 parts of potato modified starch, 3 parts of boron fiber, 5 parts of polyester fiber, hydroxypropyl methyl 6 parts of cellulose, 17 parts of glycerin, 1.5 parts of dispersant NC, 0.7 parts of sodium dodecylbenzenesulfonate, 0.5 parts of stearic acid, 0.5 parts of leveling agent DSX2000, 0.3 parts of wetting agent CF-10 , 0.4 parts of colorless cobalt, 0.1 parts of platinum catalyst, 0.4 parts of azobisisobutyrate (ethylene glycol acrylate), 0.5 parts of polyoxyethylene polyoxypropanolamine ether, 0.7 parts of paraffin emulsifier, methyl methacrylate 0.3 parts of ester-butadiene...

Embodiment 2

[0045] A kind of high-performance latex paint, by weight, comprises the following raw materials: 30 parts of butadiene-styrene emulsion, 24 parts of acrylate emulsion, 20 parts of nano-titanium oxide concentrated slurry, 12 parts of butyl acrylate, methyl methacrylate 8 parts of ester, 7 parts of superfine wollastonite, 4 parts of titanium dioxide, 5 parts of montmorillonite, 6 parts of white cement, 10 parts of potato modified starch, 2 parts of boron fiber, 3 parts of polyester fiber, hydroxypropyl methyl 4 parts of cellulose, 15 parts of glycerin, 1 part of dispersant NC, 0.5 parts of sodium dodecylbenzenesulfonate, 0.4 parts of stearic acid, 0.3 parts of leveling agent DSX2000, 0.2 parts of wetting agent CF-10, none 0.3 parts of color cobalt, 0.1 parts of platinum catalyst, 0.3 parts of azobisisobutyrate (ethylene glycol acrylate), 0.4 parts of polyoxyethylene polyoxypropanolamine ether, 0.5 parts of paraffin emulsifier, methyl methacrylate- 0.2 parts of butadiene-styrene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com